Multilayered lifting conveying device and energy-saving oven provided with same

A conveying device and lifting conveying technology, applied in the field of ovens, can solve the problems of insufficient utilization of heat energy, low work efficiency, large space occupation, etc., and achieve the effect of improving the heat cycle utilization rate, improving work efficiency and effective utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

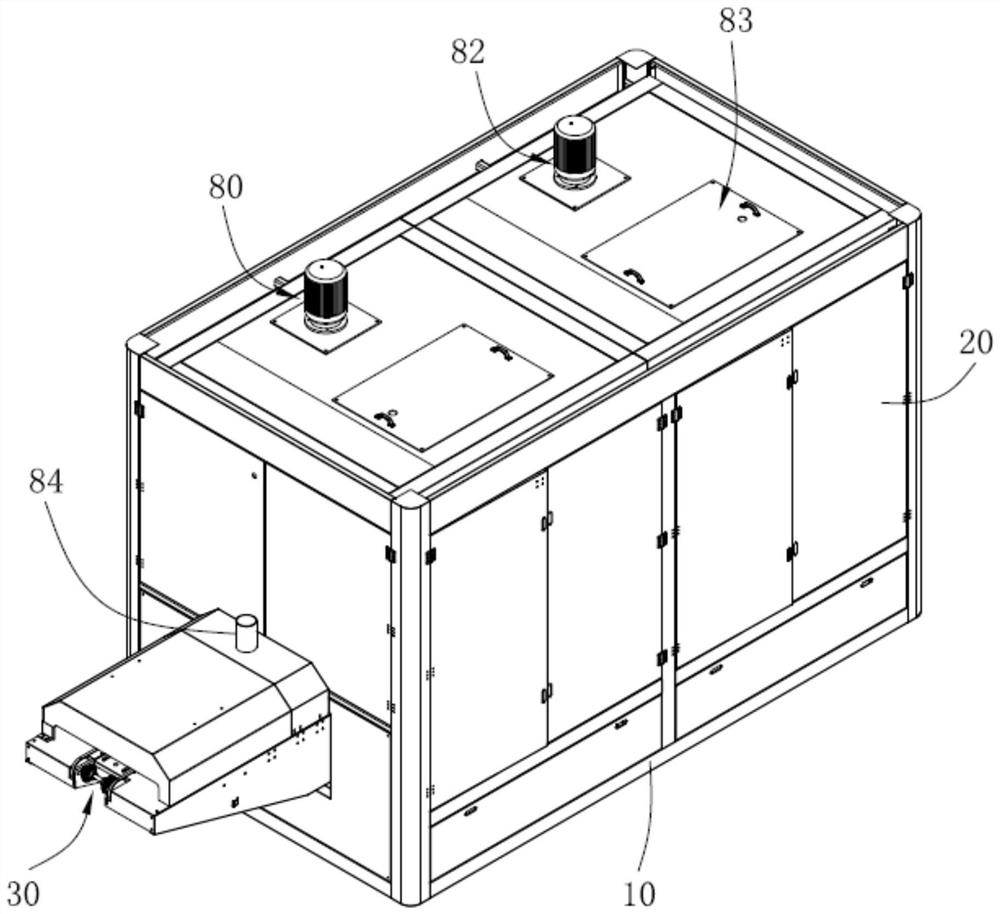

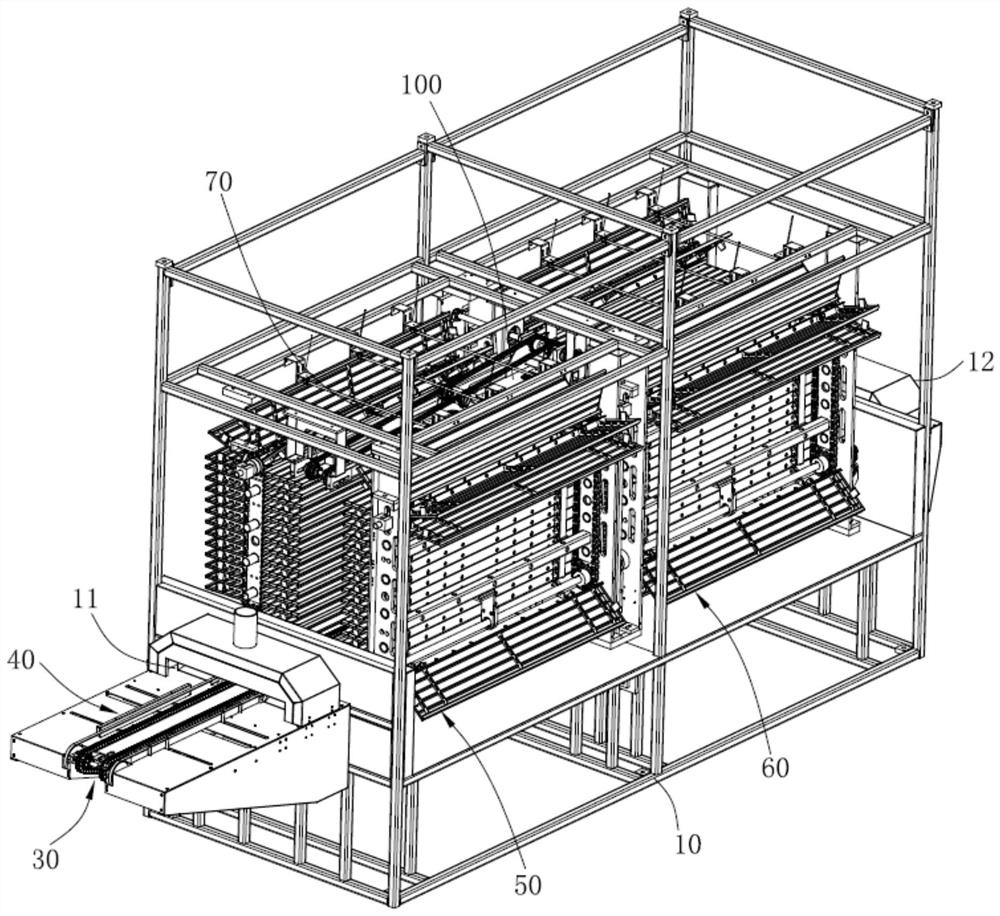

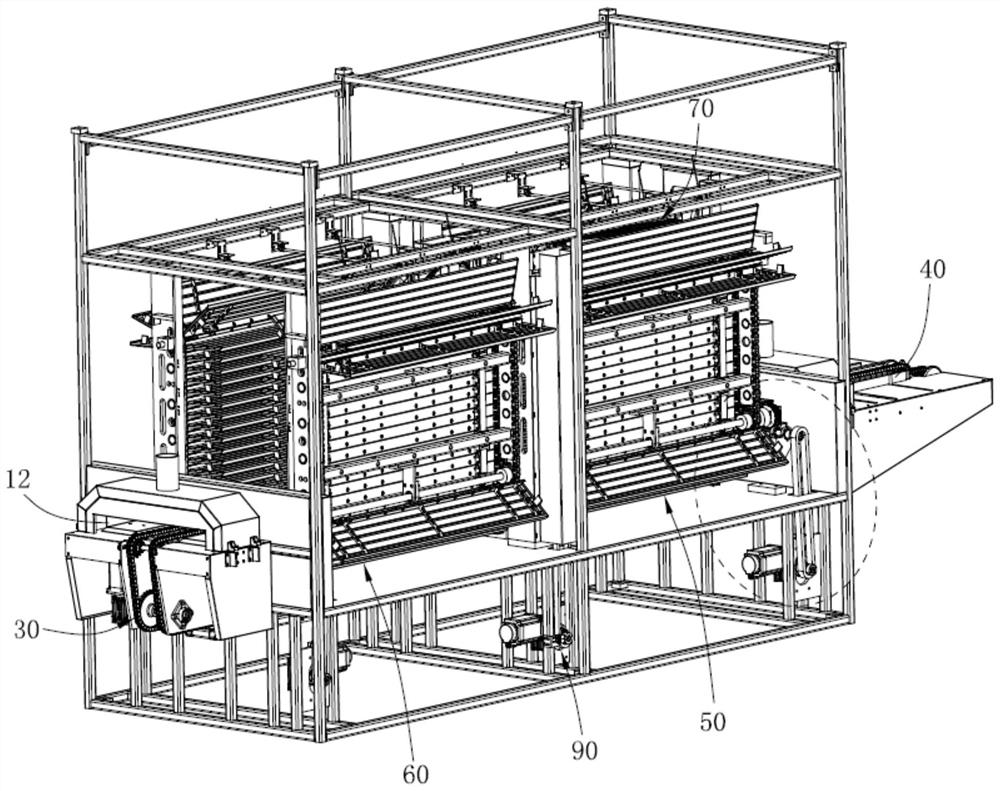

[0044] Such as Figure 1 to Figure 17 As shown, it is an energy-saving oven provided by the present invention with a multi-layer lifting and conveying device, which is used for baking the circuit board 100 or any other products that need to be baked. The energy-saving oven with multi-layer lifting and conveying device includes a frame 10, a casing 20 arranged on the outside of the frame 10, and a feeding device 30 installed in the casing 20, a positioning device 40, and a lifting and conveying device 50. Blanking conveying device 60, material pushing device 70, wind transport device 80, centering board arrangement device 90.

[0045] The casing 20 is installed on the frame 10, and a feed port 11 and a discharge port 12 are arranged between the cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com