Vacuum sealing structure of universal penetrating pipe

A vacuum sealing structure and vacuum sealing technology, which is applied in the direction of pipes, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of long replacement time, workload, time and economic cost, etc., so as to avoid excessive installation time and guarantee The effect of sealing vacuum, convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

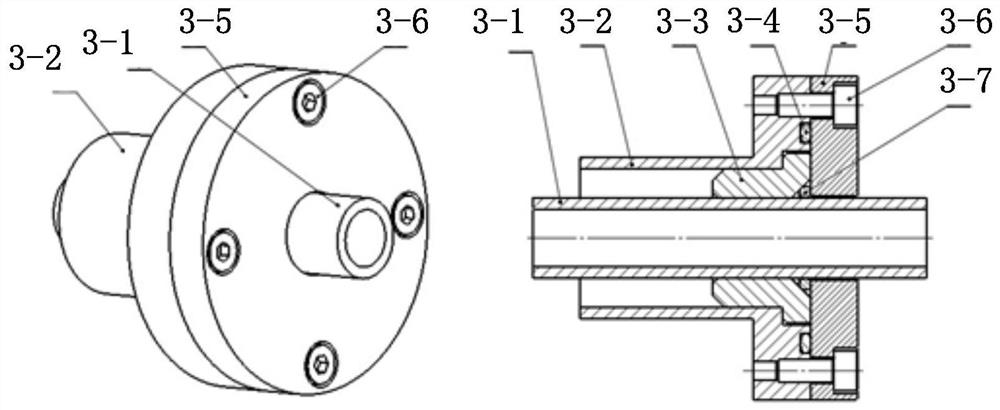

[0028] image 3 As shown, when the pipe needs to be replaced, remove 3-6 (screw), remove 3-5 (sealing flange), remove 3-7 (sealing ring), remove 3-3 (original inner core), and replace Take out 3-1 (the original pipe), install 3-1 (the new pipe), insert 3-3 (the inner core whose inner diameter matches the outer diameter of the new pipe), and install 3-7 (the outer diameter of the new pipe). Matching sealing ring), confirm that 3-4 (seal ring) is installed normally, install 3-5 (seal flange), install 3-6 (screw), and complete the vacuum seal of the new pipe.

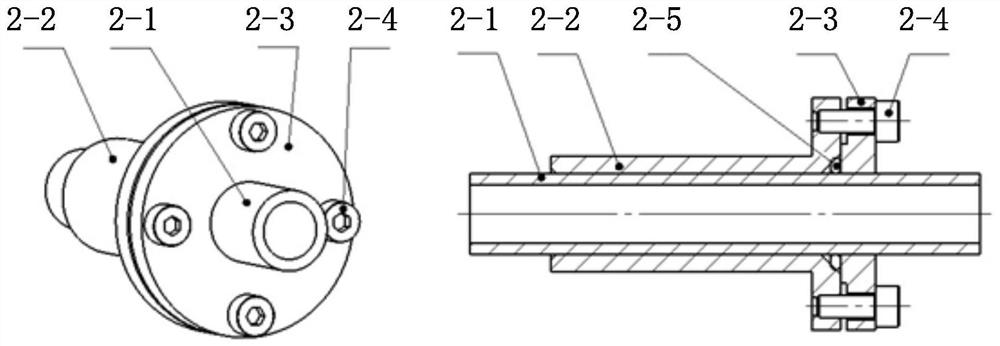

[0029] exist figure 2 In the conventional pipe-through structure, due to the need for vacuum sealing, the gap between 2-1 (pipe-through) and 2-2 (pipe-through-bottom pipe) needs to be strictly controlled, and under general site conditions, the gap between 2-1 (Pipe-through) usually needs to pass from the inside to the outside, and the operating position and space are usually limited. Therefore, in actual installation, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com