Optimization method of bolt thread height

An optimization method and thread technology, applied in the field of optimization, can solve the problems of bolt connection failure, prone to creep relaxation, etc., and achieve the effect of ensuring high strength and uniform bearing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

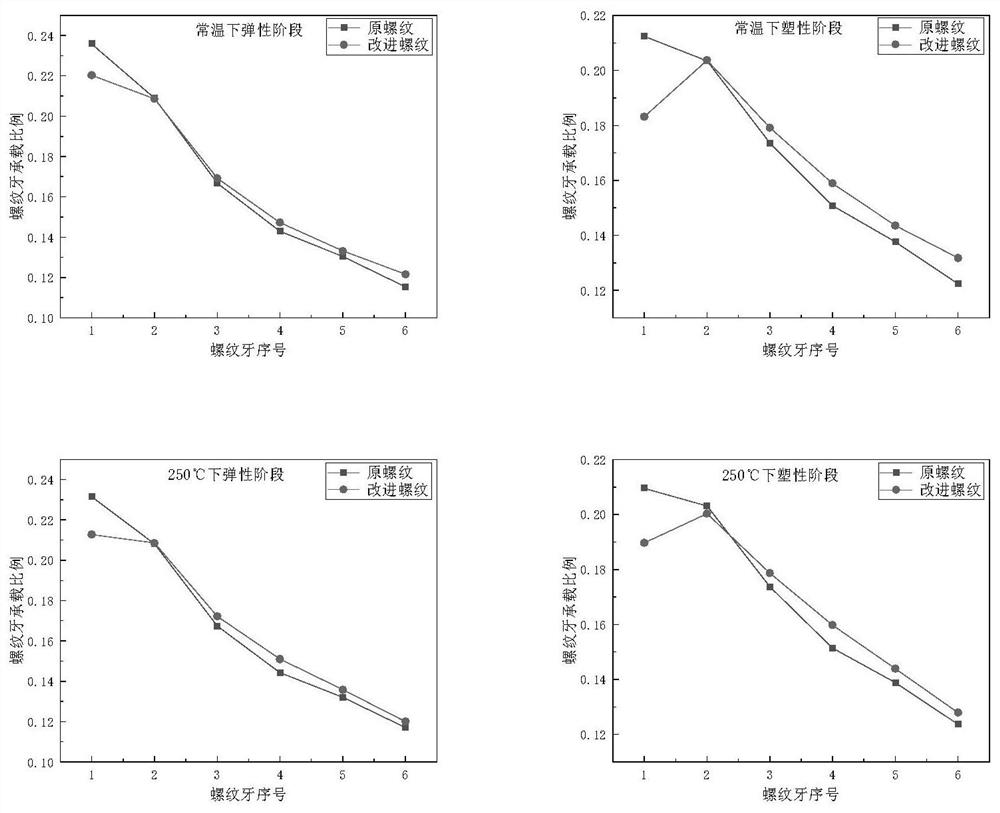

Examples

Embodiment Construction

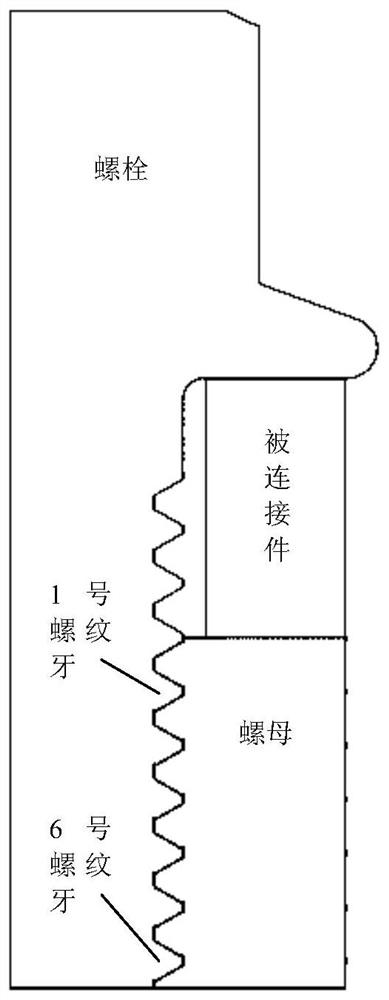

[0024] Below in conjunction with accompanying drawing, the present invention is described in further detail:

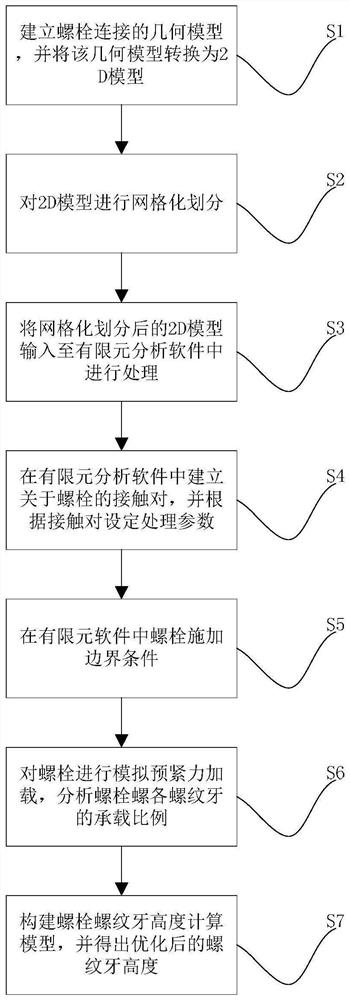

[0025] A method for optimizing the thread height of a bolt provided by the invention comprises the following steps:

[0026] S1. Establish the geometric model of the bolt connection, and convert the geometric model into a 2D model; wherein, the geometric model is realized by ProE or Catia software;

[0027] S2. Carry out grid division to 2D model; Grid division is carried out grid division by Hypermesh or Ansa software;

[0028] S3. Input the meshed 2D model into the finite element analysis software for processing; wherein, the finite element software adopts Abaqus;

[0029] S4. Establish the contact pair about the bolt in the finite element analysis software, and set the processing parameters according to the contact pair; wherein, the processing parameter setting includes the contact attribute of the thread pair and the contact attribute of the connector, including...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com