Composite material reinforced steel pipeline and preparation method thereof

A composite material and steel pipeline technology, applied in the field of oil pipeline preparation, can solve the problems of increasing pipeline processing cost and time, and achieve the effect of uniform bearing ratio and stress reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

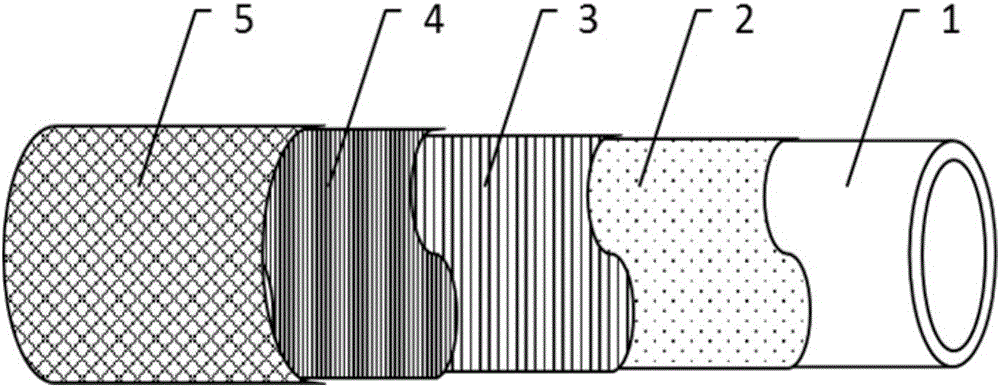

[0038] (1) Structural design: as attached figure 1 As shown, the fiber-reinforced layer 3 of this embodiment is selected Kevlar49, and its modulus is 124GPa, and the composite material reinforced layer 4 is selected from E-type glass fiber reinforced epoxy resin, and its modulus is 35-45GPa, compared to the modulus of steel 206GPa , the modulus of Kevlar is closer, so as a reinforcement layer close to the steel pipe, it plays the role of transferring stress. The elongation at break of the fiber-reinforced layer 3 and the composite material-reinforced layer 4 is very close, both about 2%. The similar elongation at break ensures that the two structural layers are destroyed at the same time, and there will be no phenomenon that a single structural layer is loaded, which is beneficial to have two Structural layers enhance the effect while playing.

[0039] Due to the hoop stress (σ s ) and axial stress (σ a ) is related by σ s =2σ a , that is, if the requirements of the axial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com