Method for automatically regulating the size of a slot of a nozzle assembly and control and/or regulation system

A nozzle and gap technology is applied in the field of automatically adjusting the nozzle outlet gap size of the nozzle mechanism, which can solve problems such as inability to achieve, and achieve the effect of reducing cross effects and saving repeated operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In the following figures, the same components are marked with the same reference numerals for the sake of overview.

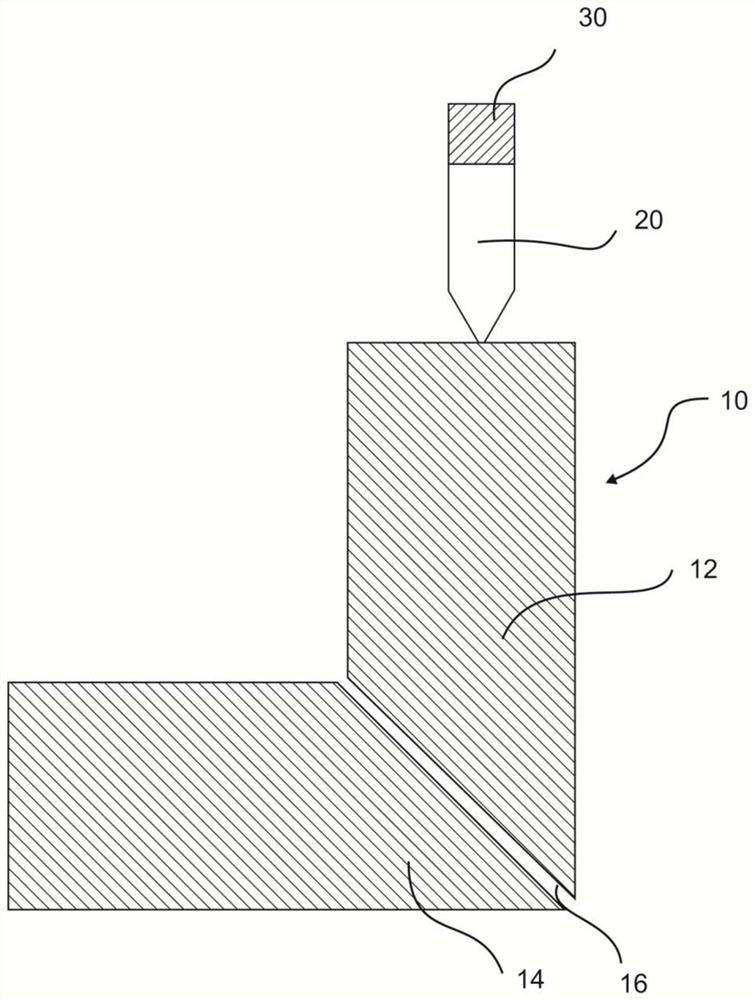

[0054] figure 1 A schematic diagram of a nozzle mechanism 10 according to the invention for automatic adjustment of nozzle outlet gap size according to a first embodiment is shown. The nozzle mechanism 10 has a first nozzle lip 12 and a second nozzle lip 14 . Between the nozzle lips 12 and 14 there is a nozzle outlet gap 16 for the controllable adjustment of the thickness profile of the conveyable melt. Here, a melt, for example a plastic melt, is conveyed through the nozzle outlet gap 16 to produce a flat film. Depending on the size or height of the nozzle exit gap 16, the melt thickness is adjusted or changed.

[0055] In order to adjust the size or height of the nozzle outlet gap 16 , a plurality of adjustment elements 20 , in particular approximately 120 adjustment elements 20 , are provided on the first nozzle lip 12 . exist figure 1 Only one a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com