An internal feedback precision closed hydrostatic turntable

A precision closed, static pressure turntable technology, applied in the direction of grinding slides, grinding workpiece supports, grinding racks, etc., can solve the complicated steps of adjusting the flow and pressure of the workbench, affecting the overall accuracy, aesthetics and performance of the workbench Poor functionality and other problems, to achieve the effect of improving rigidity and anti-overturning ability, improving the dimensional accuracy of grinding, and reducing the difficulty of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below with reference to the drawings and specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

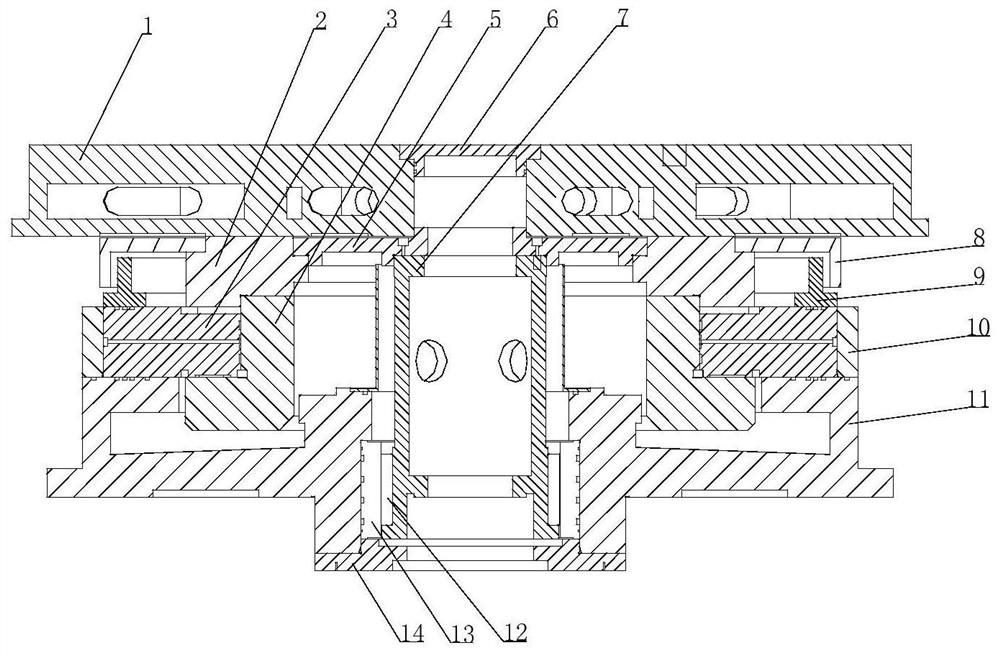

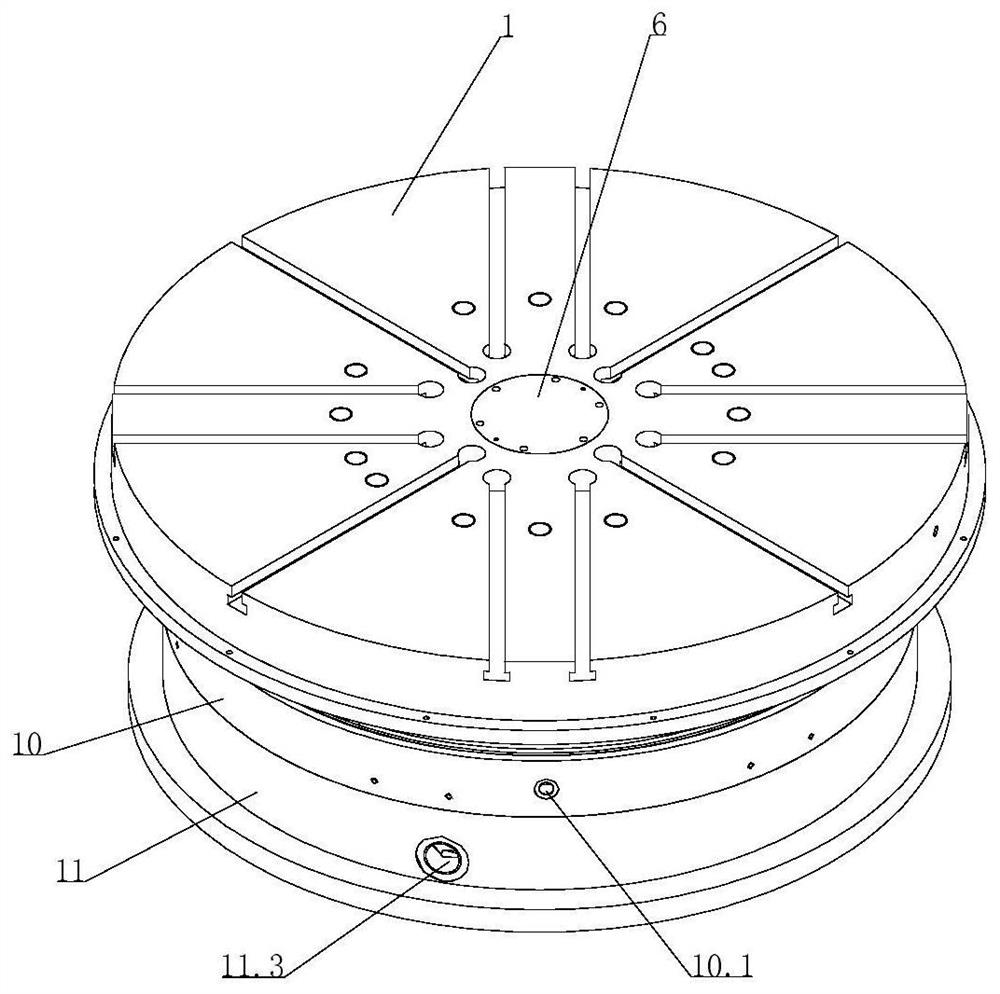

[0026] An internal feedback precision closed hydrostatic turntable, see Figure 1-4 , the invention point is: including the base 11 , the internal feedback type hydrostatic bearing, the worktable 1 , the torque motor stator 13 , the torque motor rotor 12 , the transmission shaft 7 and the transmission disc 5 .

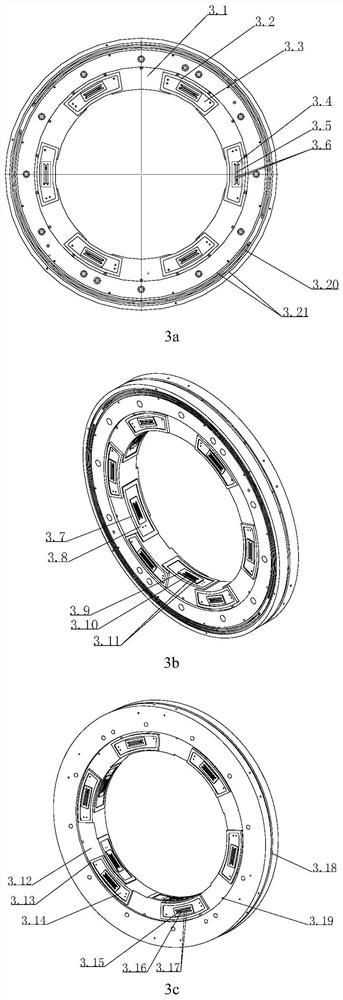

[0027] The internal feedback type hydrostatic bearing is composed of an upper guide rail 2, a lower guide rail 4, a hydrostatic bearing body 3 and a heat-fit sleeve 10 which is sleeved on the outer ring of the hydrostatic bearing body. The upper guide rail and the lower guide rail are fixedly connected up and down coaxially through screws; the static pressure bearing body is fixed and fixed on the upper end of the base t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com