Electrostatic electret loading device for melt-blown cloth

An electrostatic electret and loading device technology, which is applied in textiles and papermaking, fiber processing, physical processing, etc., can solve the problems that the electrostatic electret effect of metal tungsten wire is not ideal and the working efficiency is not high enough, and is suitable for popularization and use with simple structure. , the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

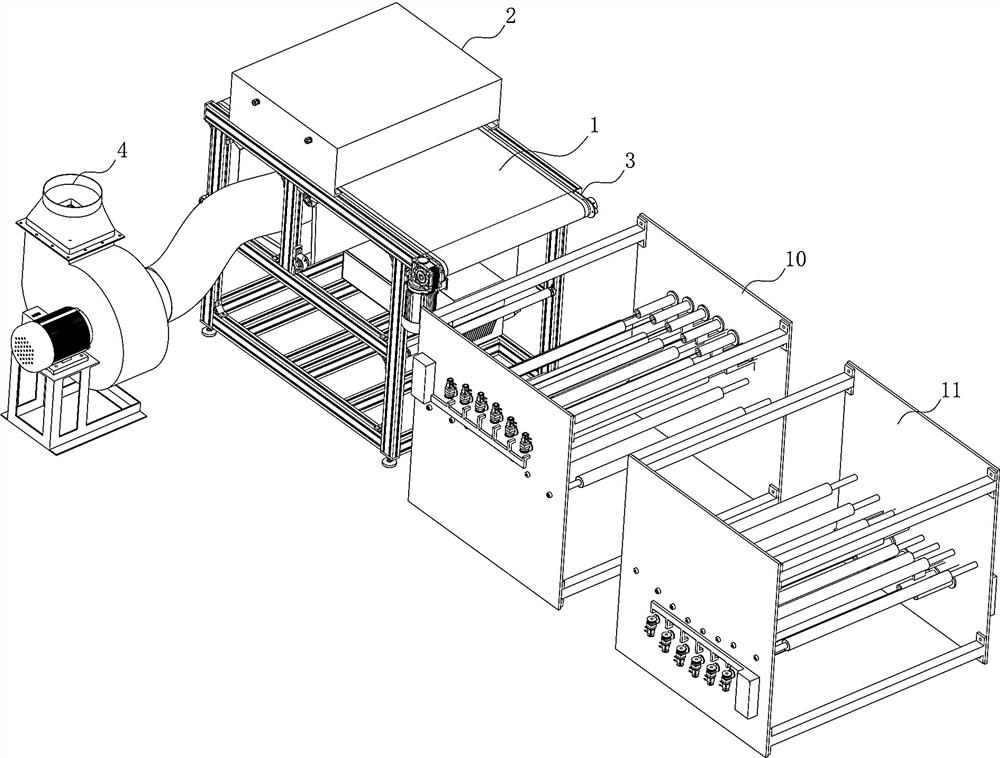

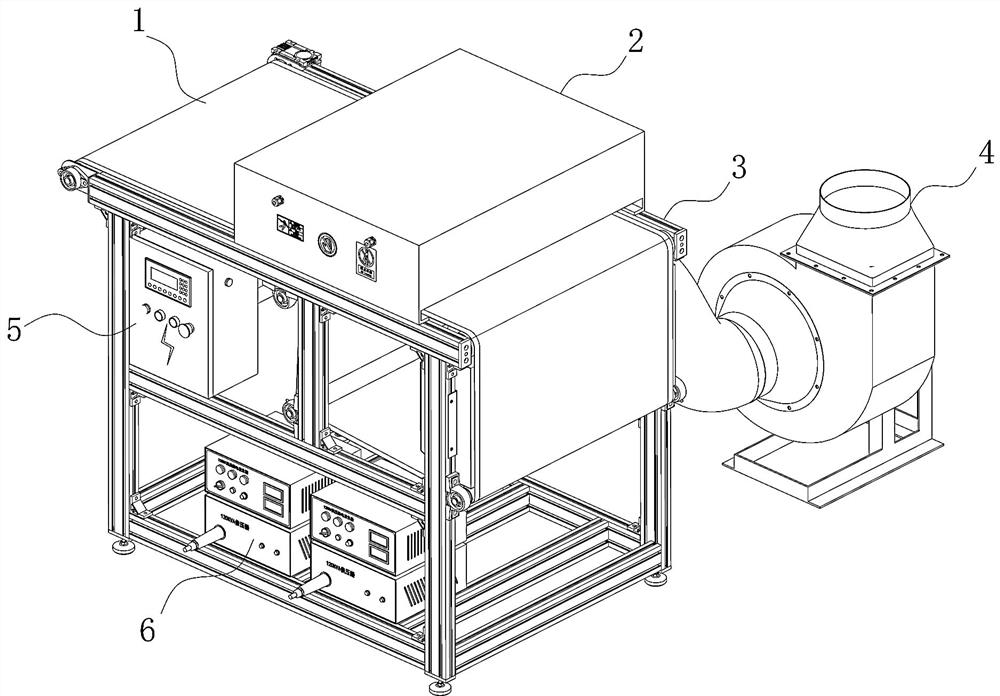

[0037] like Figures 1~14 As shown, a kind of electrostatic electret loading device for melt-blown cloth, the melt-blown cloth collection support 3 is provided with a collection conveyor belt 1, the top of the collection conveyor belt 1 is provided with a preliminary electrostatic electret device 2, and the melt-blown cloth collection support 3 The discharge end is provided with a front electret 10, one side of the front electret 10 is provided with a reverse electret 11, the front electret 10 and the reverse electret 11 are rotationally symmetrical, and the front electret 10 is provided with a plurality of There are several grounding rollers 14 , an electret wire 13 is arranged above a single grounding roller 14 , and both ends of the electret wire 13 are fixed on the front electret frame 10 through the discharge seat 12 . Using multiple electret structures to electret the non-woven fabric, the preliminary electrostatic electret device 2 performs preliminary electret to the n...

Embodiment 2

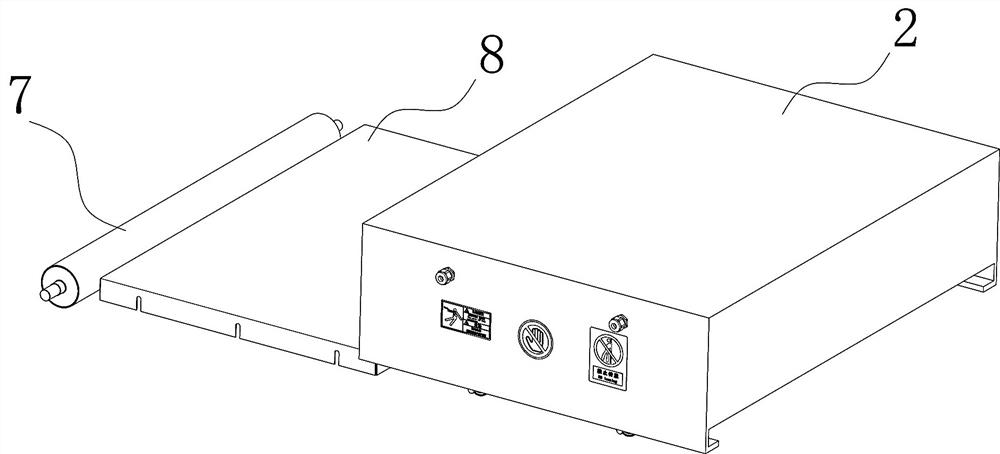

[0045] Further description in conjunction with embodiment 1, as Figures 1~14 As shown, a kind of electrostatic electret loading device for melt-blown cloth, the melt-blown cloth collection support 3 is provided with a collection conveyor belt 1, and the top of the collection conveyor belt 1 is provided with a preliminary electrostatic electret device 2, and a preliminary electrostatic electret device 2. There are static electricity generating needles 203 inside, and a plurality of static electricity generating needles 203 are arranged on a support that can be lifted and lowered. The preliminary electrostatic electret device 2 is provided with a plurality of cylinders 202. The telescopic ends of the cylinders 202 are connected to the support. 1 is provided with an electrostatic grounding plate 8 below. With this structure, the air cylinder 202 is used to drive the bracket on which a plurality of static electricity generating needles 203 are installed to rise and fall, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com