Particles for electronic paper and manufacturing method thereof

A technology of electronic paper and particles, applied in chemical instruments and methods, preparation of microspheres, microcapsule preparations, etc., can solve problems such as unsatisfactory display stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

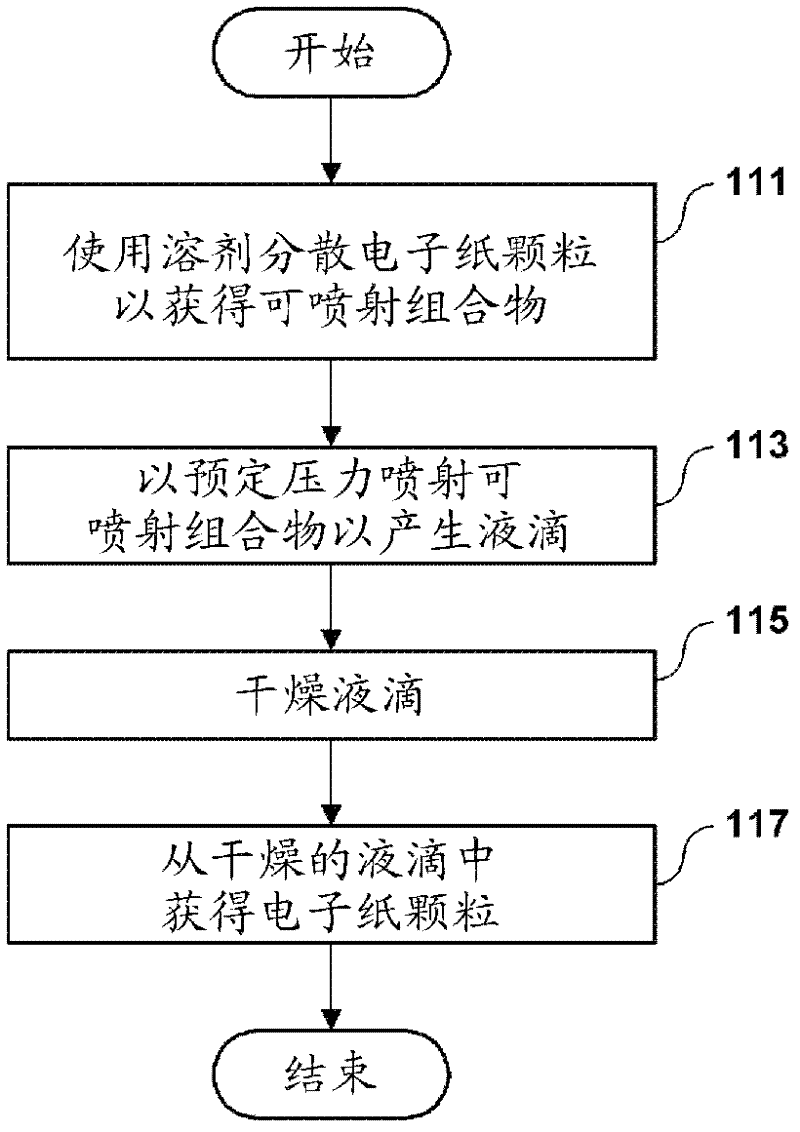

[0063] The electronic paper particle composition is dispersed using a solvent to obtain a sprayable composition. Here, the electronic paper particle composition includes a polymer resin, a charge control agent, and a pigment. A styrene-acrylate copolymer was used as a polymer resin, p-50 (a plasticizer having a positive charge) was added to the polymer resin at a content of 0.5%, and carbon black (black pigment) was used as a pigment.

[0064] The sprayable composition was sprayed through a two-fluid nozzle at a pressure of 3 MPa to produce droplets.

[0065] The droplets were dried by using air at 90° C. until the solvent content of the droplets became less than 1%, and electronic paper particles were obtained from the dried droplets.

Embodiment approach 2

[0067] A sprayable composition is obtained by dispersing the electronic paper particle composition using a solvent. Here, the electronic paper particle composition includes a polymer resin, a charge control agent, and a pigment. A polyester resin was used as a polymer resin, E-88 (Morflex 130) (a plasticizer having a negative charge sold by Orient Chemical in Japan) was added to the polymer resin at a content of 0.5%, and titanium dioxide (white pigment) was used as a pigment.

[0068] The sprayable composition was sprayed through a two-fluid nozzle at a pressure of 5 MPa to produce droplets.

[0069] The droplets were dried by using air at 80° C. until the solvent content of the droplets became less than 1%, and electronic paper particles were obtained from the dried droplets.

Embodiment approach 3

[0071] A sprayable composition is obtained by dispersing the electronic paper particle composition using a solvent. Here, the electronic paper particle composition includes a polymer resin, a charge control agent, and a pigment. Styrene-butadiene copolymer was used as the polymer resin, E-80 (Kesscoflex DBT) (plasticizer having a negative charge) was added to the polymer resin at a content of 0.5%, and titanium dioxide (white pigment) was used as the pigment .

[0072] The sprayable composition is sprayed through a two-fluid nozzle at 4 MPa to produce droplets.

[0073] The droplets were dried by using air at 100° C. until the solvent content of the droplets became less than 1%, and electronic paper particles were obtained from the dried droplets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com