Guide rail mechanism for restraining rotation of brake pad supports and clamp braking device provided with guide rail mechanism

A technology of brake pad holders and guide rails, which is applied in the direction of axially joined brake components, brake types, brake components, etc., can solve the problems of unfavorable brake pad holders with extra torque, mutual incompatibility, and influence on anti-deflection effects, etc. , to achieve the effects of improving safety and reliability, avoiding abnormal eccentric wear, and reducing maintenance and repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

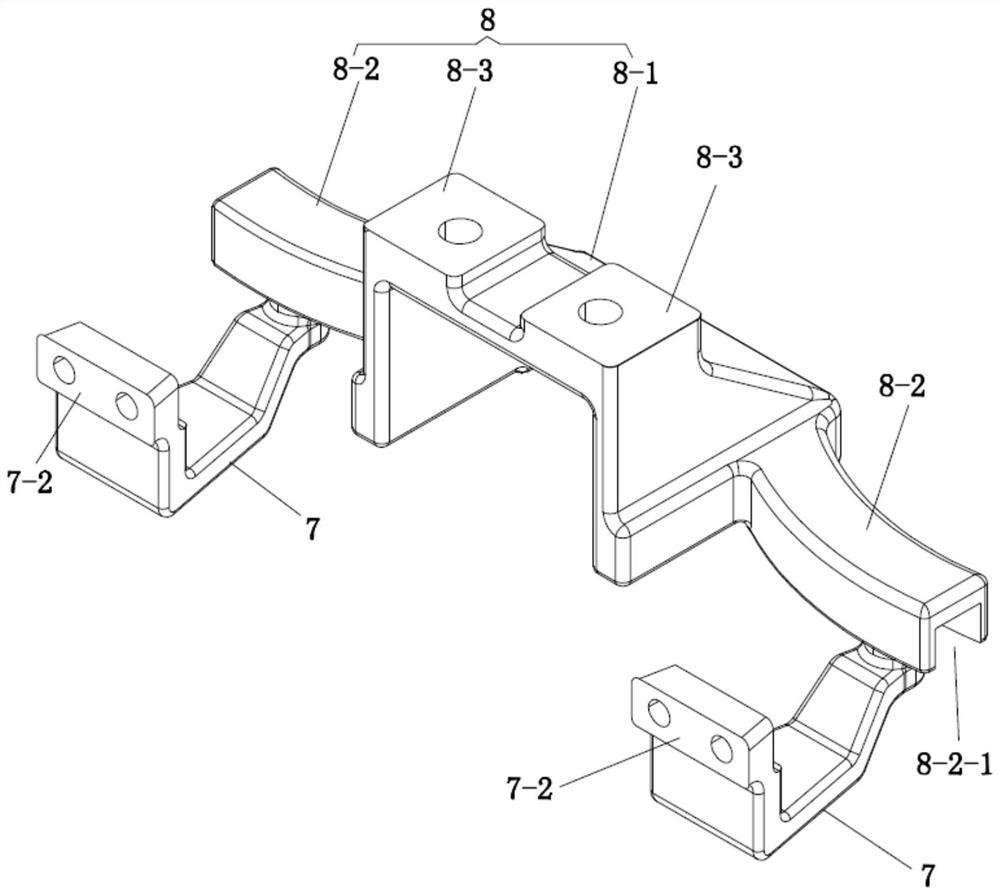

[0049]The guide rail mechanism for restricting the rotation of the brake pad holder in this embodiment is as followsfigure 1 As shown, the guide rail seat 8 is included. The mounting part of the guide rail seat 8 is composed of a support body 8-1 with two spaced upper mounting platforms 8-3 at one end. The upper mounting platform 8-3 is used for connecting the caliper brake device The bottom of the clamp body 1 is connected. The support may be a solid structure, but preferably a hollow structure that helps reduce weight. The bottom edges of the vertical extending surfaces outside the two upper installation platforms 8-3 of the installation part respectively extend out of the guide rail 8-2 through reinforcing ribs. Preferably, the inner end of the guide rail 8-2 is arranged at the rear end of the bottom edge of the vertical extension surface, which is more conducive to the track design of the guide groove; the guide rail 8-2 has an end connected to the connecting rod 7 (extending fr...

Embodiment 2

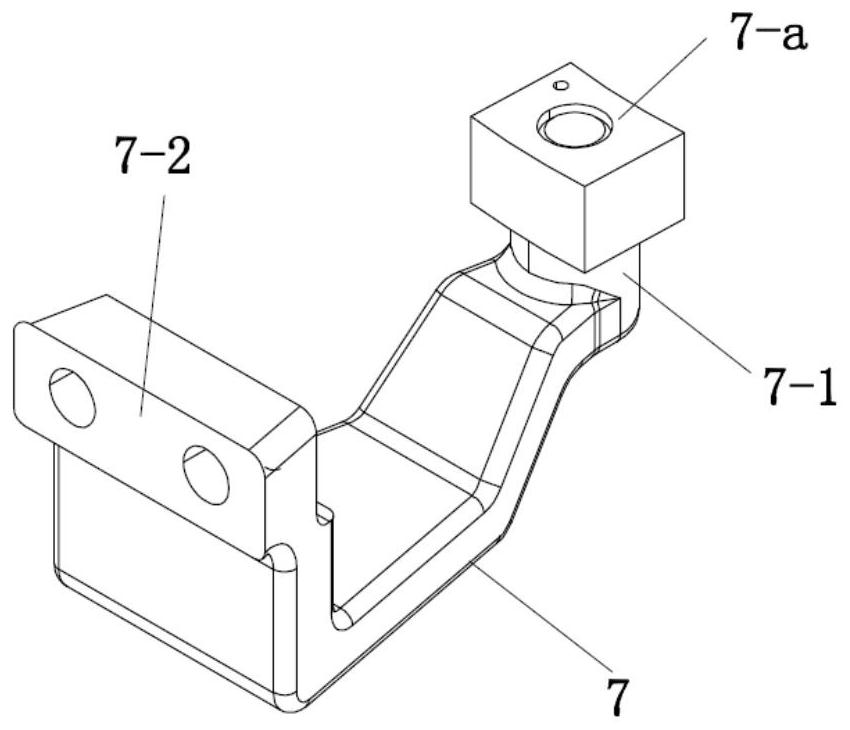

[0064]The guide rail mechanism for restricting the rotation of the brake pad holder in this embodiment is as followsFigure 8 withPicture 9 As shown, the difference from the first embodiment is that the guide rail 8-2 has a front opening guide groove 8-2-1 which forms a cam pair with one end of the connecting rod 7; the connecting rod 7 is in the shape of a plate, and one end is directly along the length direction. A cylindrical connecting column 7-1 is extended to form a cam pair directly with the front opening guide groove 8-2-1 of the guide rail 8-2; the other end extends away from the connecting column 7-1 in the length direction and is directly formed The front installation platform 7-2, the front installation platform 7-2 is fixedly connected with the brake pad holder on the same side. Therefore, the structure is simpler. Since the front mounting platform 7-2 is used to connect with the brake pad, the width of the other end of the connecting rod 7 is greater than the width of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com