An antifreeze faucet based on the heat diffusion technology of the die heat source

A faucet and thermal diffusion technology, applied in the field of faucets, can solve problems such as inability to supply water, freezing and cracking faucet pipes, inconvenient application, etc., and achieve the effect of ensuring safe use and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

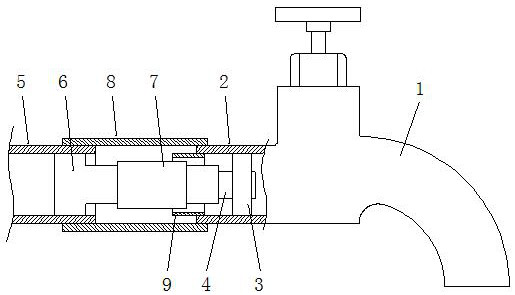

[0035] See figure 1 , an antifreeze faucet based on the heat diffusion technology of the core heat source, comprising a faucet body 1 and a water supply pipe 5, the water inlet end of the faucet body 1 is connected through the water inlet pipe 2, and the inner cavity of the water inlet pipe 2 is sleeved with The isolation plate 3 is embedded with an inner connection pipe 4, the two ends of the inner connection pipe 4 run through the left and right sides of the isolation plate 3, and the end of the water inlet pipe 2 away from the faucet body 1 is sleeved with a water supply pipe. The outer connecting pipe 8 matched with the pipe 5 is threadedly connected between the water inlet pipe 2 and the outer connecting pipe 8. The outer connecting pipe 8 is threaded on the outside of the water supply pipe 5, and the outer connecting pipe 8 is connected to the water supply pipe respectively. 5 and the faucet body 1, can realize the through connection between the water supply pipe 5 and t...

Embodiment 2

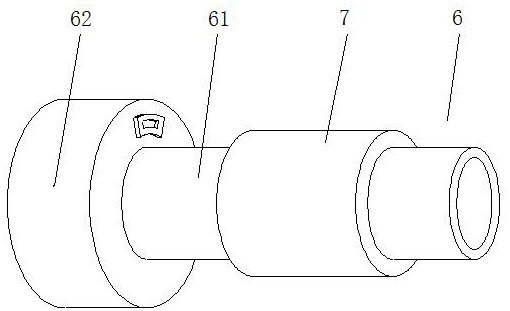

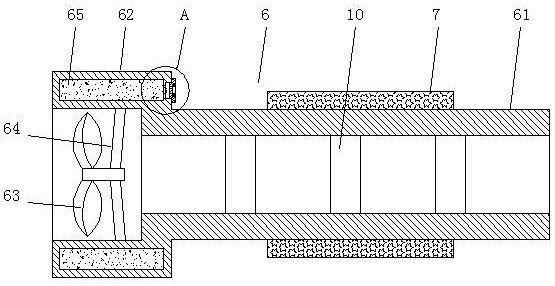

[0039] See Figure 2-6 The difference from Embodiment 1 is that the core pipe 6 includes a thawing pipe 61 on the inner connecting pipe 4 and a surge pipe 62 sleeved in the water supply pipe 5, and the gap between the surge pipe 62 and the water supply pipe 5 is It is a threaded connection, and the surge pipe 62 connects the thawing pipe 61 through. The space is threaded, the electric heating jacket assembly 7 is set on the outside of the thawing pipe 61, the core pipe 6 is connected to the water supply pipe 5 through the surge pipe 62, and the core pipe 6 is connected to the inner connecting pipe 4 through the thawing pipe 61, which can realize The core pipe 6 is used to connect the water supply pipe 5 and the faucet body 1 to ensure smooth water supply of the faucet body 1; and the electric heating jacket assembly 7 can directly heat the thawing pipe 61, so that the whole core pipe 6 can be thawed, thereby ensuring the faucet. Body 1 is normally used in cold weather;

[00...

Embodiment 3

[0045] See Figure 7 The difference from Embodiment 1 is that the external connection pipe 8 includes a base pipe 81 that is matched with the water inlet pipe 2 and the water supply pipe 5 respectively, and the base pipe 81 is threaded on the water inlet pipe 2 and the water supply pipe 5 respectively. On the outside, the spiral direction between the base pipe 81 and the water inlet pipe 2 is completely opposite to the spiral direction between the base pipe 81 and the water supply pipe 5; the water inlet pipe 2 and the water supply pipe 5 can be connected through the base pipe 81;

[0046] The outer circular surface of the base pipe 81 is evenly provided with a number of rotating teeth 82, the base pipe 81 and the rotating teeth 82 are integrally formed, and the outer side of the base pipe 81 is provided with a thermal insulation layer that matches the rotating teeth 82. Layer 83, the outer side of the heat preservation layer 83 is provided with a heat insulation layer 84 that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com