Combined deslagging device

A technology for discharging hoppers and installing rods, which is applied in the field of slag discharging equipment for incinerators, and can solve problems such as collection, unfavorable user dumping of slag materials, subsequent processing, and difficult slag materials, so as to improve slag discharge efficiency and increase slag discharge efficiency , easy delivery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

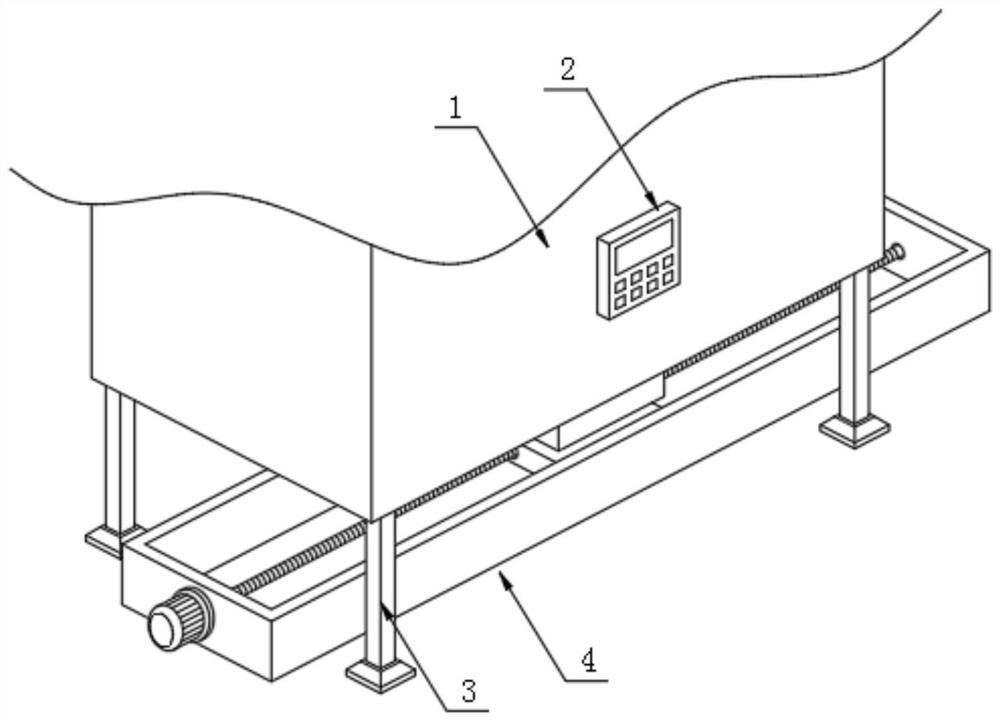

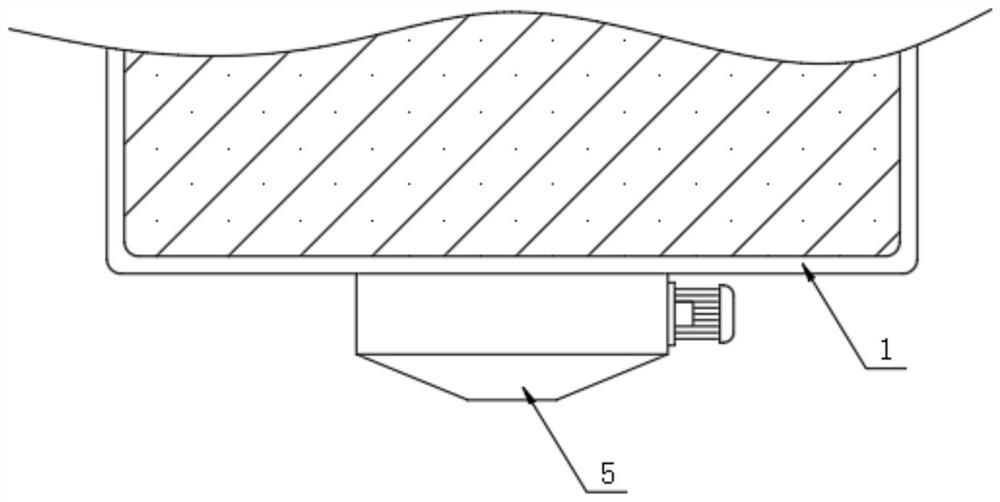

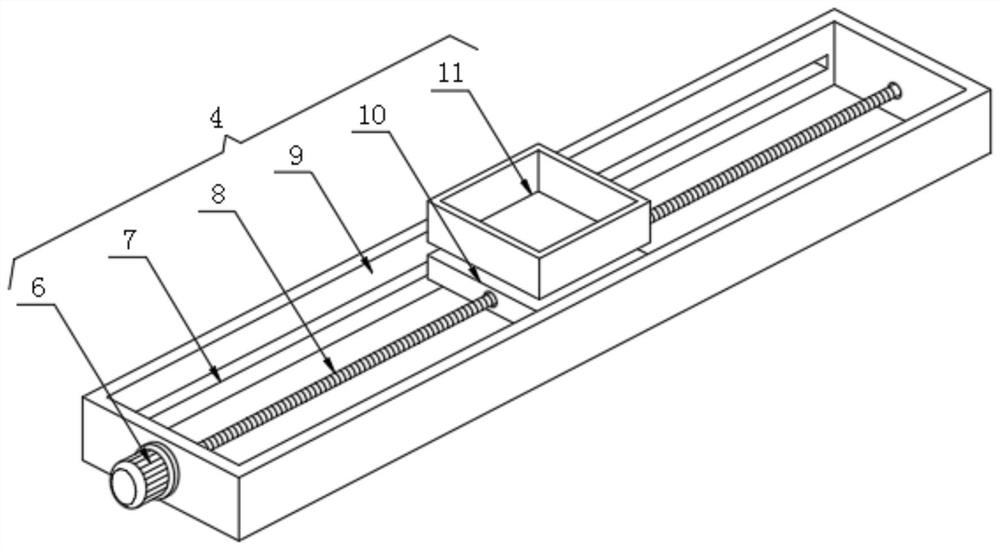

[0024] see Figure 1~6 , in an embodiment of the present invention, a combined slagging device includes an incinerator 1, a discharge hopper 5 is affixed to the center of the lower surface of the incinerator 1, and supports are affixed to the four corners of the lower surface of the incinerator 1 Leg 3, the controller 2 is fixed on the front surface of the incinerator 1, and the battery is fixed on the rear surface of the incinerator 1, the model of the controller 2 is DKC-Y110, and the feeding device 4 is installed under the discharge hopper 5 , the feeding device 4 includes a servo motor 6, a limit groove 7, a threaded rod 8, a mounting seat 9, a fixed block 10 and a storage box 11, the outer side of the mounting seat 9 is fixedly connected with the servo motor 6, and the inner wall of the mounting seat 9 is two Limiting grooves 7 are provided on the sides, and a fixed block 10 is slidably connected to the inside of the mounting base 9. The driving end of the servo motor 6 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com