Disinfection module and air purification device

A technology of air intake cavity and exhaust cavity, which is applied in the field of air purification, can solve the problem of high cost of disinfection modules, and achieve the effect of low cost and reduced cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The disinfection module of the air purification equipment in the prior art usually uses electric heating equipment to heat the filter screen or the air inside the air purification equipment, so as to kill bacteria and viruses intercepted on the filter screen or bacteria and viruses in the air. The power consumption of electric heating equipment is high, and the customer consumes a lot of electricity when using the product, resulting in high product cost.

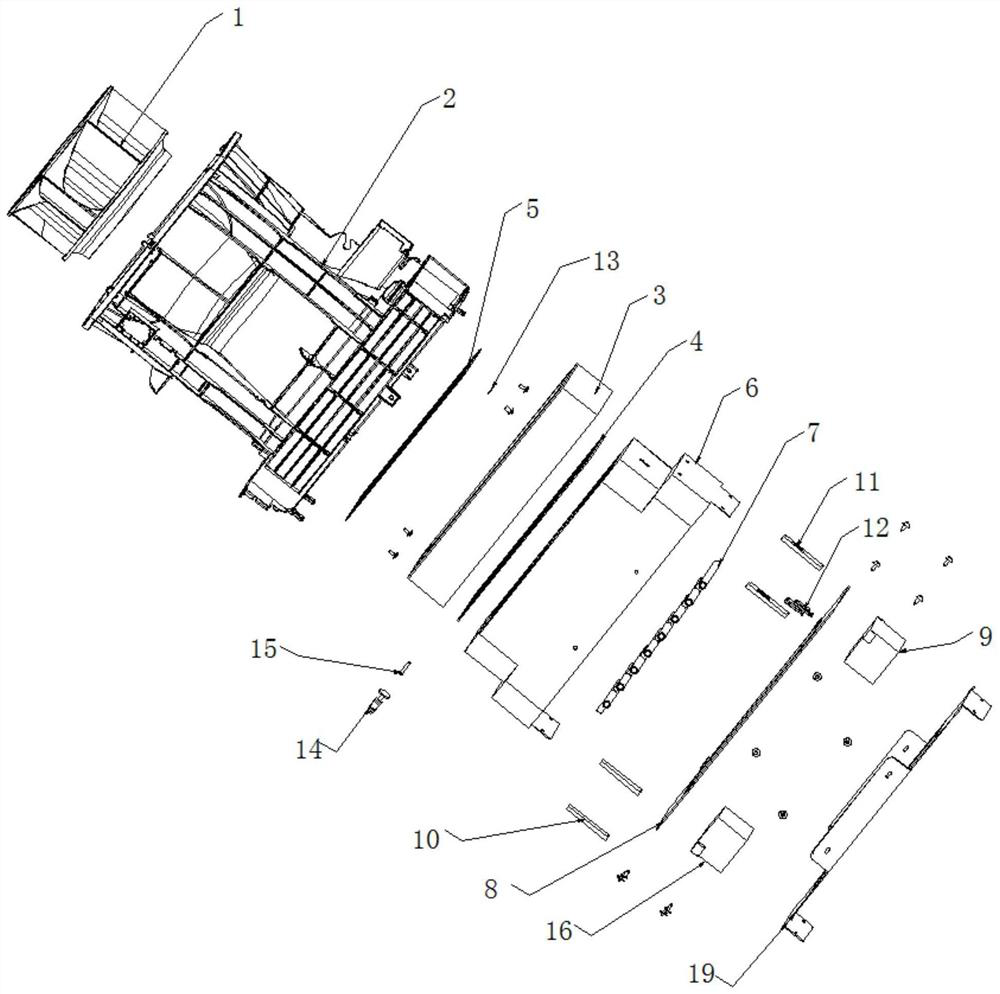

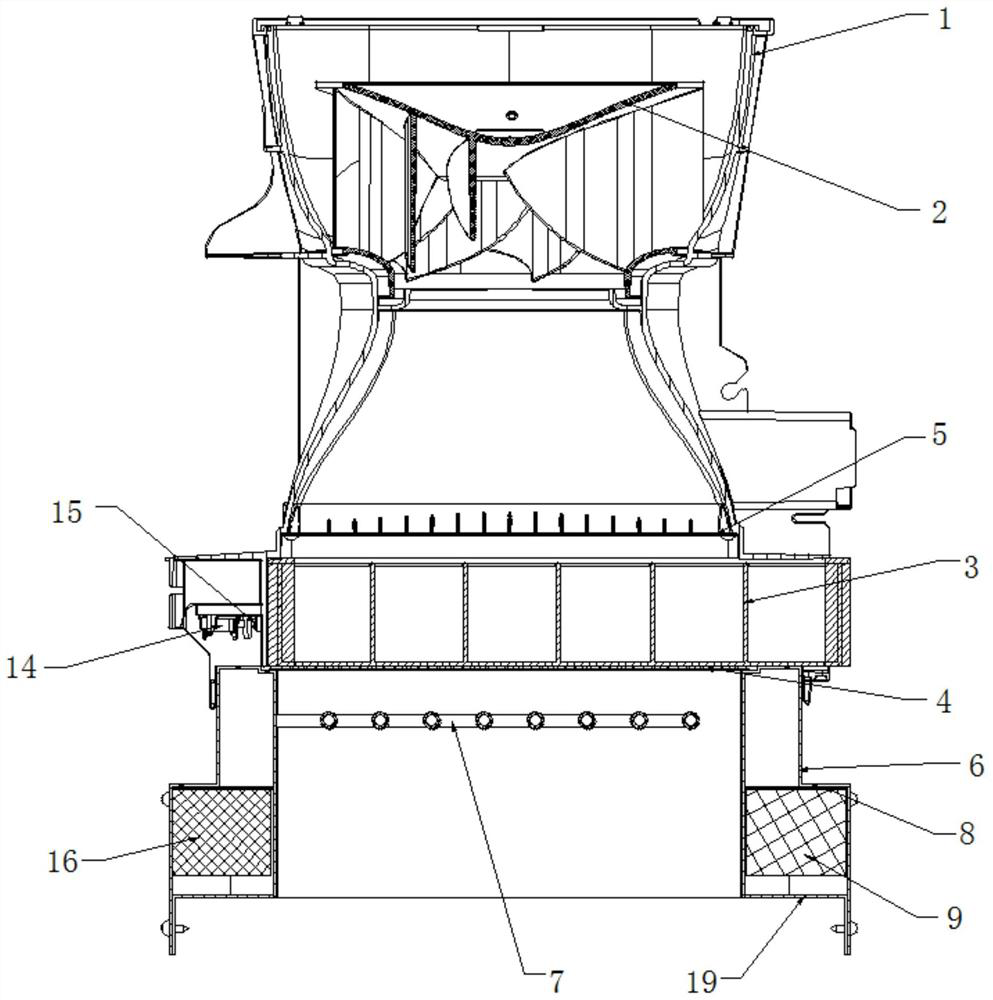

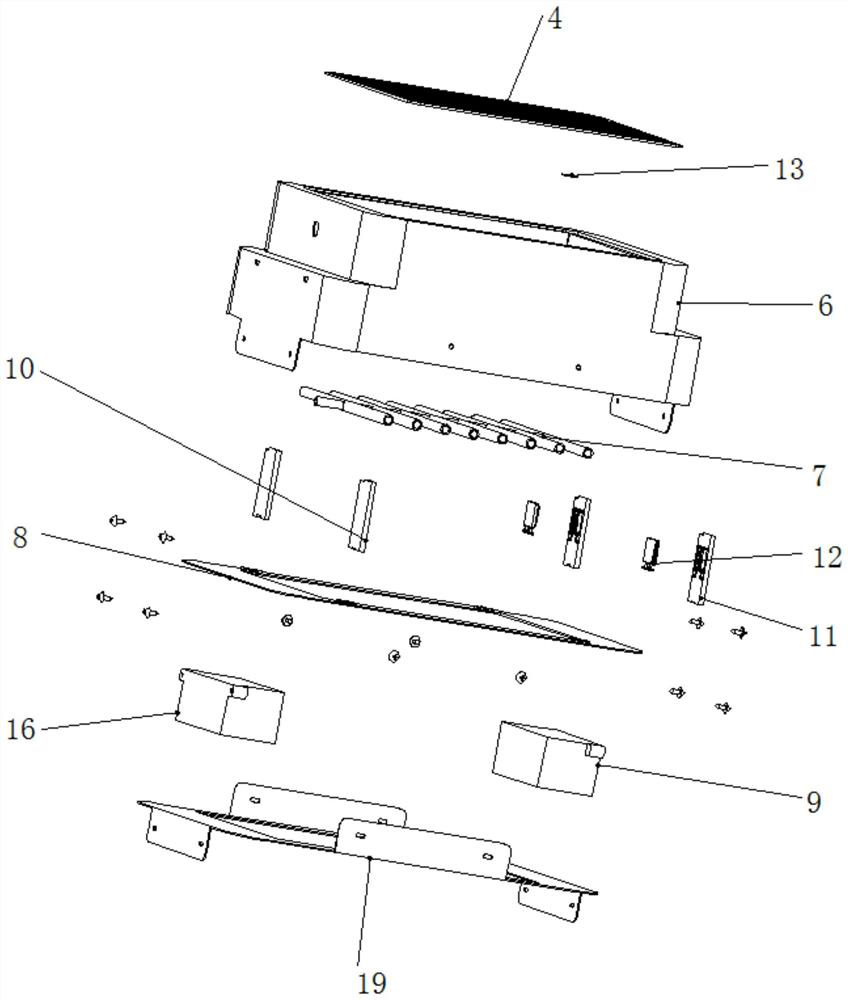

[0041] For this reason, this embodiment provides a kind of disinfection module, in one embodiment, as Figure 3 to Figure 7 As shown, the disinfection module includes a heating chamber 6 , a heating pipe 7 , and an air intake and ignition control device 9 .

[0042] Wherein the heating chamber 6 has a heat outlet, and the heat outlet is suitable for being arranged opposite to the filter screen 3; the heating pipe 7 is arranged in the heating chamber 6; the air intake and ignition control device 9 is used to control th...

Embodiment 2

[0056] This embodiment provides an air purification device, including the disinfection module provided in the above embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com