A heat dissipation cover grounding package structure and process thereof

A technology of packaging structure and heat dissipation cover, which is applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problems of unstable connection, easy damage of heat dissipation cover, and high temperature fusing, etc., and achieve the stability of conduction Good, good heat dissipation effect, ensure the effect of grounding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

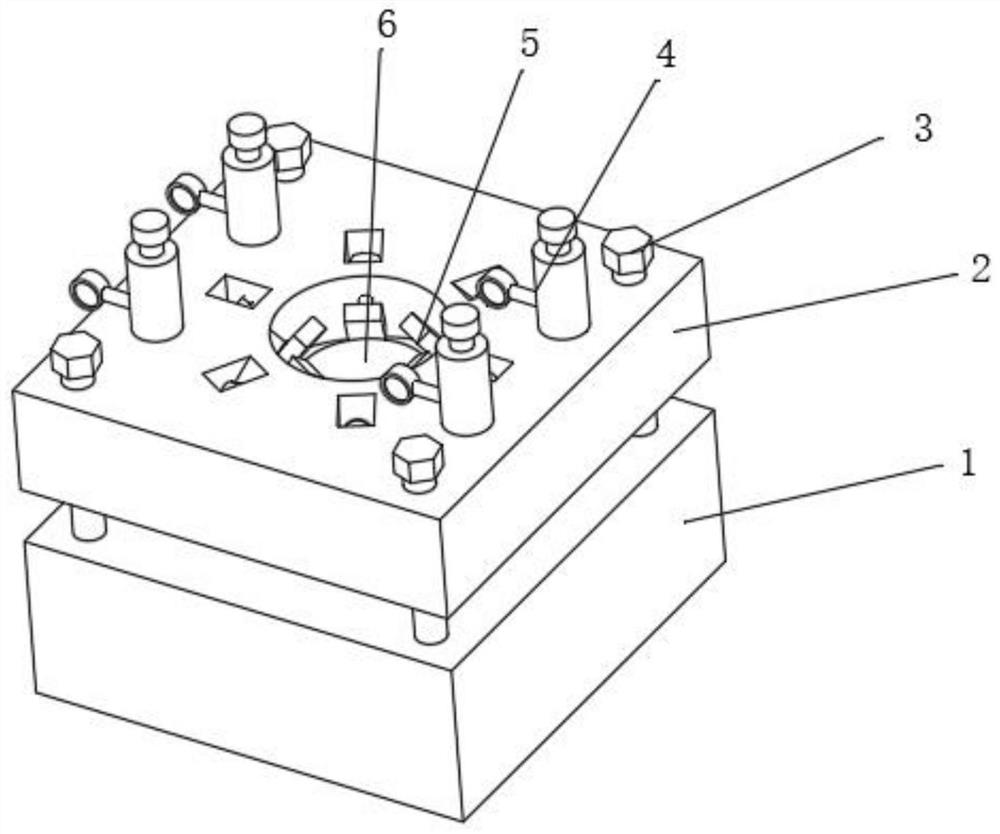

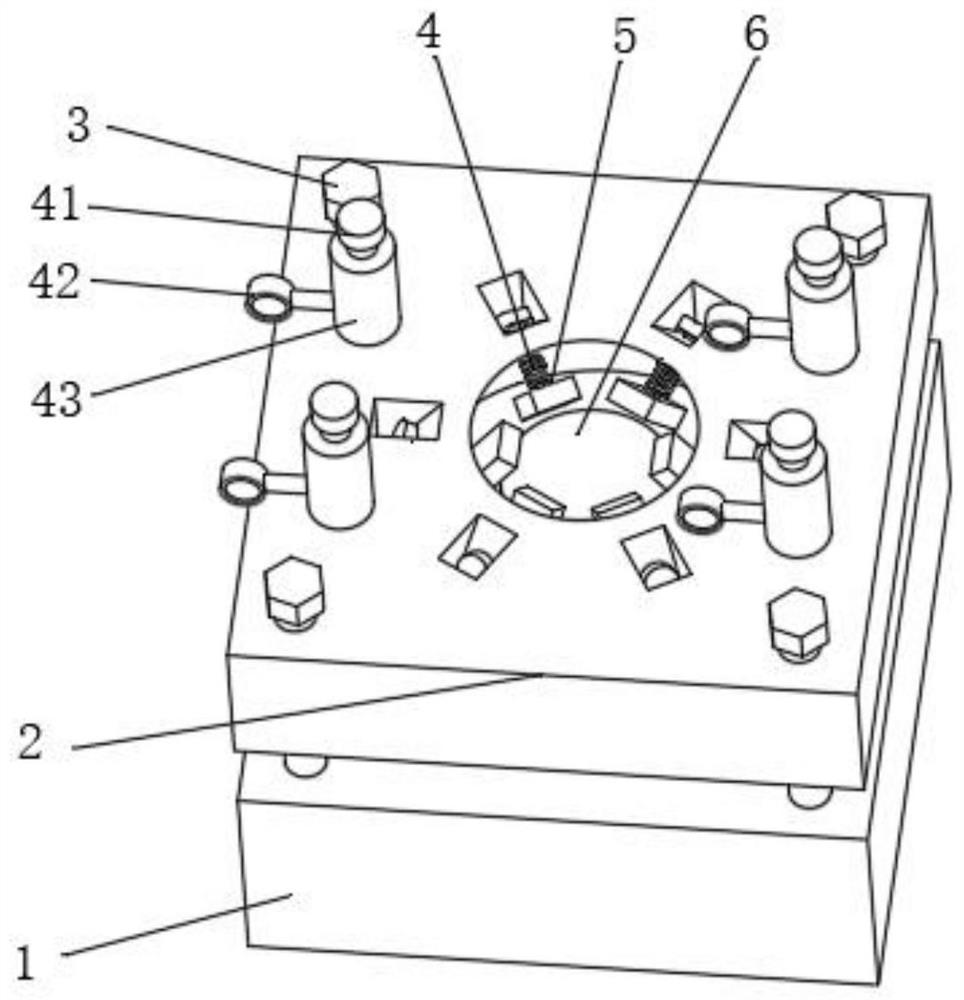

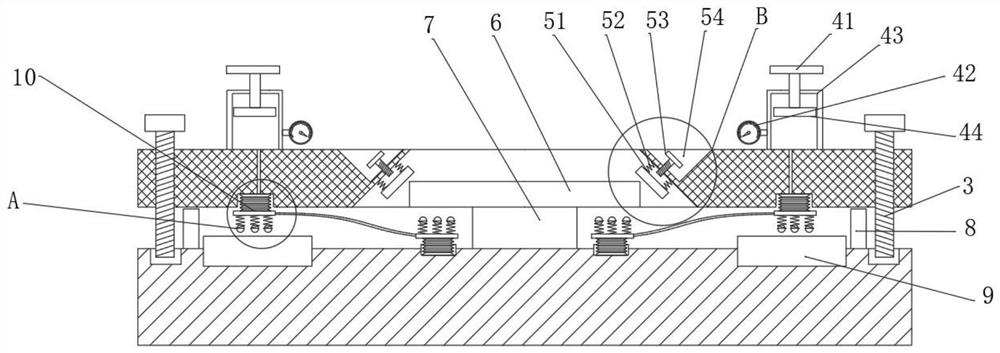

[0032] As an embodiment of the present invention, six rubber pads 51 are arranged in an annular matrix on the hole wall of the through hole on the inclined surface in the packaging board 2 , the positioning screw 53 is arranged corresponding to the rubber pad 51 , and the end surface of the positioning screw 53 is connected to the rubber pad 51 . tangent to the top side.

[0033] As an embodiment of the present invention, the pressurizing assembly 4 includes an extrusion screw 41, an air pressure gauge 42, a cylinder 43 and a piston 44. A piston 44 is installed inside the cylinder 43, and the extrusion screw 41 is threaded through the cylinder 43 through thread fit. Inside the top side wall of the cylinder 43, a gas pressure gauge 42 is fitted with the bottom of the cylinder 43.

[0034] As an embodiment of the present invention, the contact assembly 10 includes an extrusion airbag 101, a conductive plate 102, an expansion spring 103, a conductive ball 104, and a limit groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com