Photovoltaic module

A photovoltaic module and reflective technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve problems such as cell splits, and achieve the effects of convenient processing, reliable connection, and long-term reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

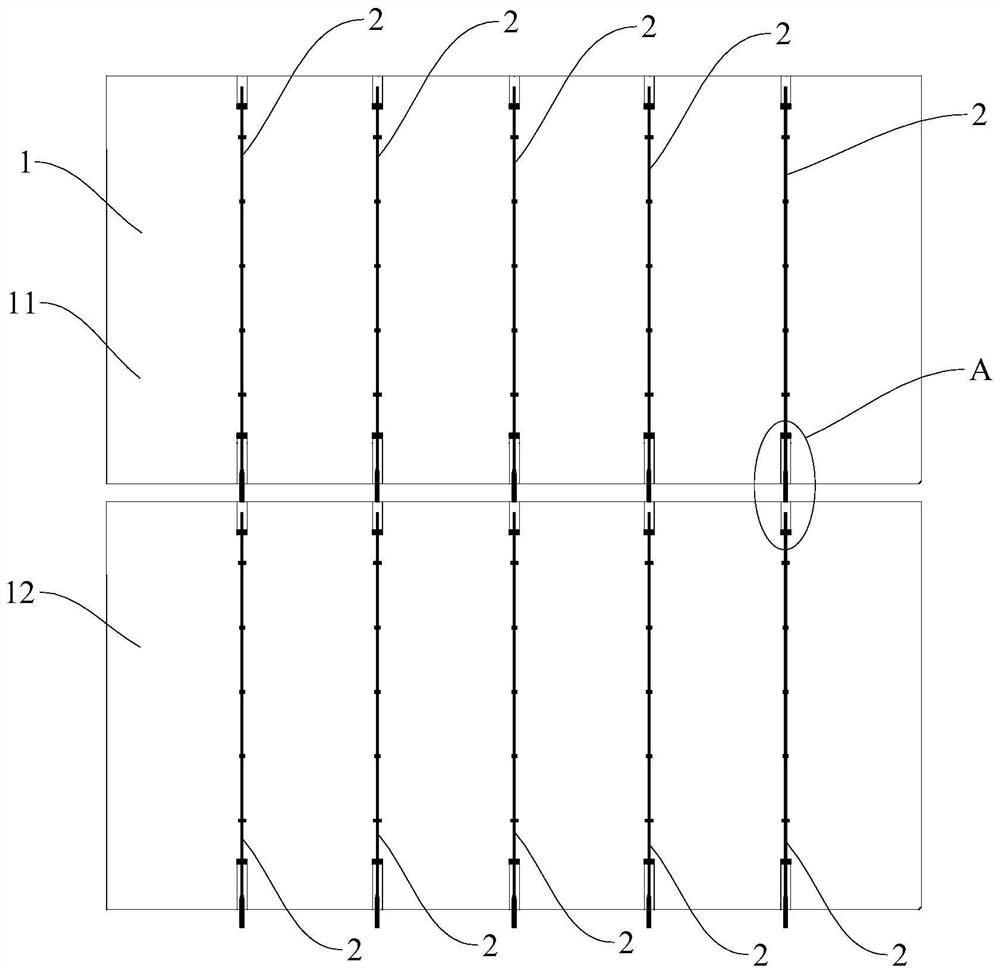

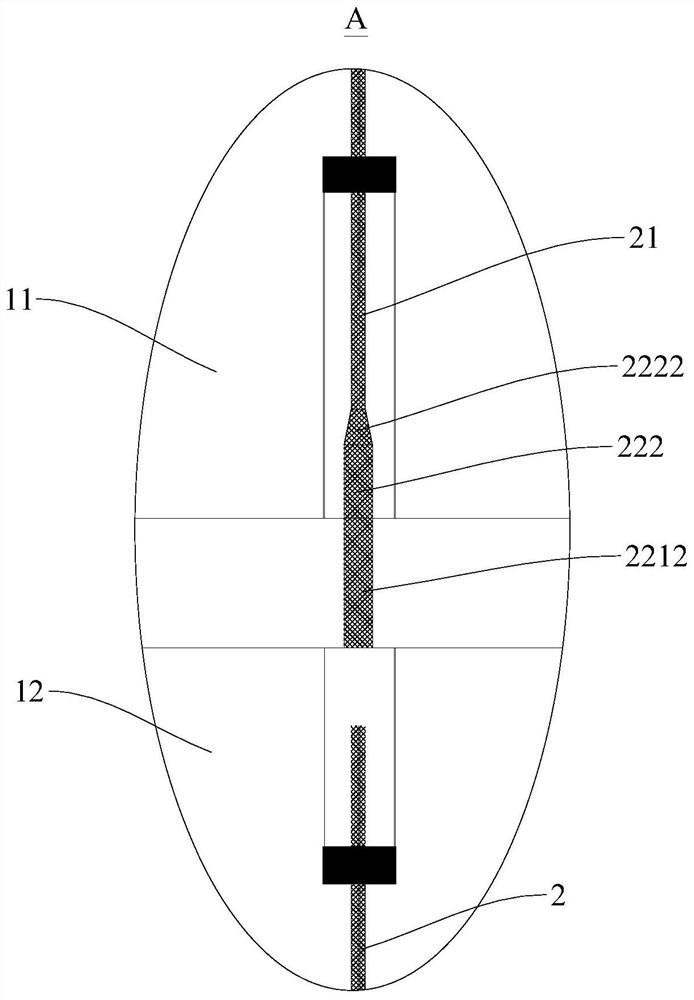

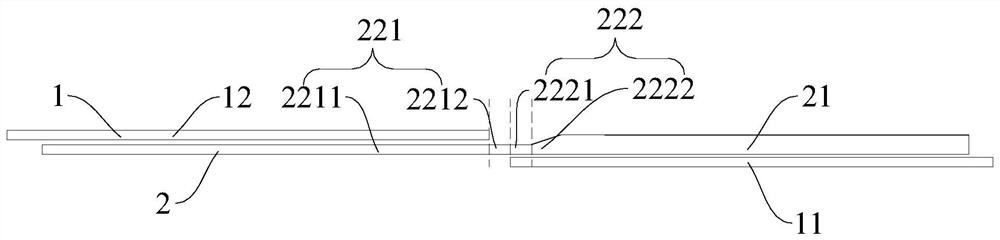

[0061]In this embodiment, asFigure 1a-Figure 1c withimage 3 As shown, the photovoltaic module is a mosaic module, and there is a gap between the first cell 11 and the second cell 12. From right to left, the interconnect structure 2 includes a reflective section 21, a first transition portion 2222, a first connection portion 2221, a second sub-connection section 2212 and a first sub-connection section 2211 in order. The entire interconnecting structure 2 may be an integrally formed part, that is, the reflective section 21, the first transition portion 2222, the first connection portion 2221, the second sub-connection section 2212, and the first sub-connection section 2211 are integrally formed during the processing. Their materials can be the same, and there is no obvious dividing line. The widths of the first connecting portion 2221, the second sub-connecting section 2212 and the first sub-connecting section 2211 are equal (or very close in width), and both are larger than the width...

Embodiment 2

[0065]In this embodiment, asFigure 2a-Figure 2c withimage 3 As shown, the photovoltaic module is a shingled module, and the end of the first cell 11 and the end of the second cell 12 are overlapped. From right to left, the interconnect structure 2 includes a reflective section 21, a first transition portion 2222, a first connection portion 2221, a fourth sub-connection section 2214 and a third sub-connection section 2213 in order. The entire interconnecting structure 2 can also be an integrally formed part, that is, the reflective section 21, the first transition portion 2222, the first connecting portion 2221, the fourth sub-connecting section 2214, and the third sub-connecting section 2213 are integrally formed during processing. , Their materials can be the same, and there is no obvious dividing line. The widths of the first connecting portion 2221, the fourth sub-connecting section 2214 and the third sub-connecting section 2213 are equal (or very close in width), and both are la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com