Solid component separator control device, solid component separating device, marine exhaust gas scrubber system, and marine diesel engine

A technology of solid composition and control device, which is applied in the direction of engine control, use of liquid separating agent, and propulsion device engine, etc., can solve problems such as concentration reduction, increase in washing water volume, and difficulty in discharging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

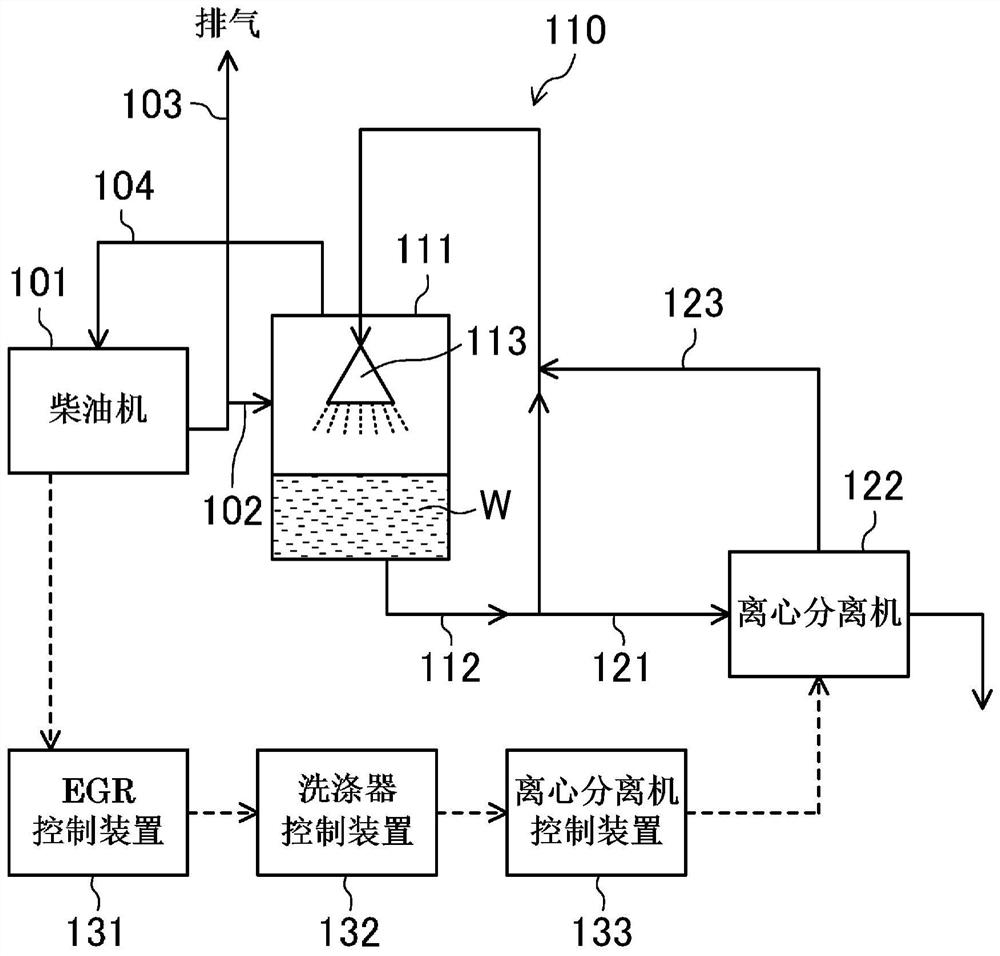

[0016] Next, an example of an exhaust gas scrubbing system as an embodiment of the present invention will be described in detail with reference to the drawings. Among them, the exhaust gas washing system removes dust from the exhaust gas of the diesel engine.

[0017] (Brief structure of exhaust gas scrubbing system)

[0018] Such as figure 1 As shown, the exhaust gas scrubbing system includes a scrubbing device 110 and a centrifugal separation device (solid component separation device). Among them, the washing device 110 captures particulate matter (solid content) such as unburned carbon contained in the exhaust gas of the diesel engine 101, and the centrifugal separation device (solid content separation device) has the function of removing the washing water W captured in the washing device 110. The centrifuge 122 (solid component separator) for solid content in (processed fluid).

[0019] More specifically, the scrubber 110 has a scrubber 111, and part of the exhaust gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com