Electrolytic disinfection structure and dish-washing machine

A dishwasher and electrolysis bin technology, which is applied in the electrolysis process, electrolysis components, washing machine/washing machine for tableware, etc., can solve the problems of poor performance of parts and loss of effect after a period of use, and ensure reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

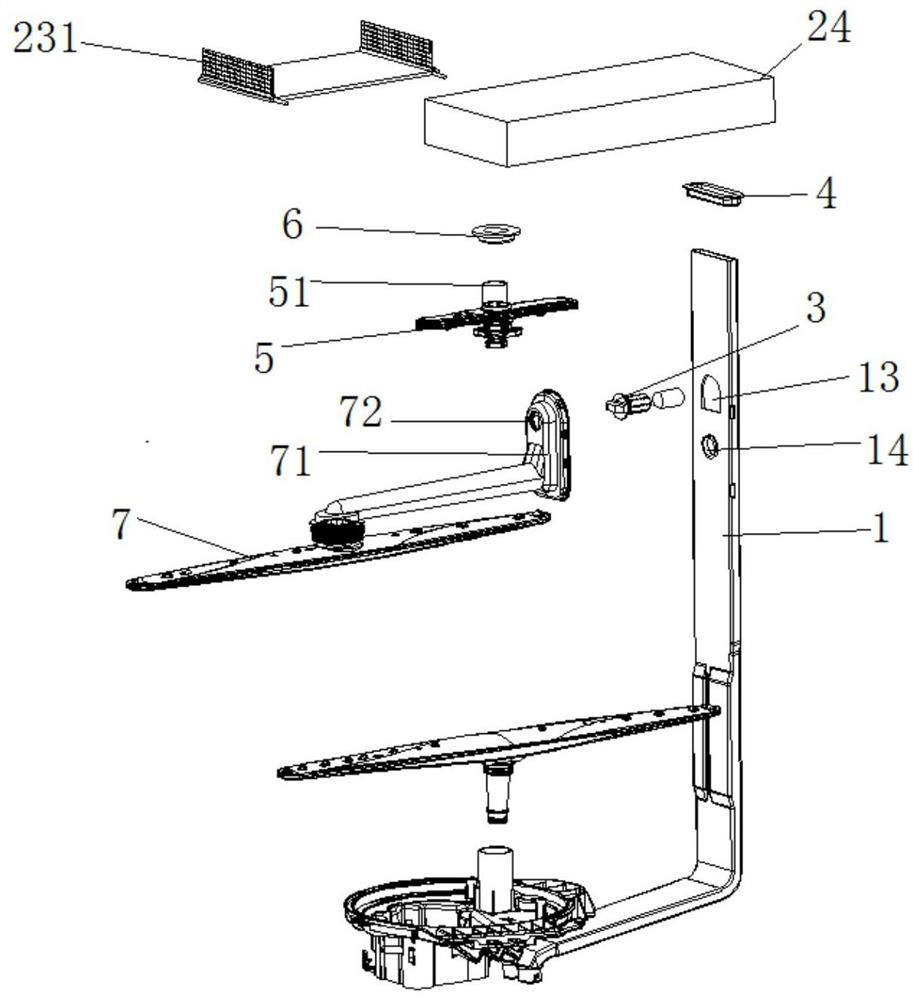

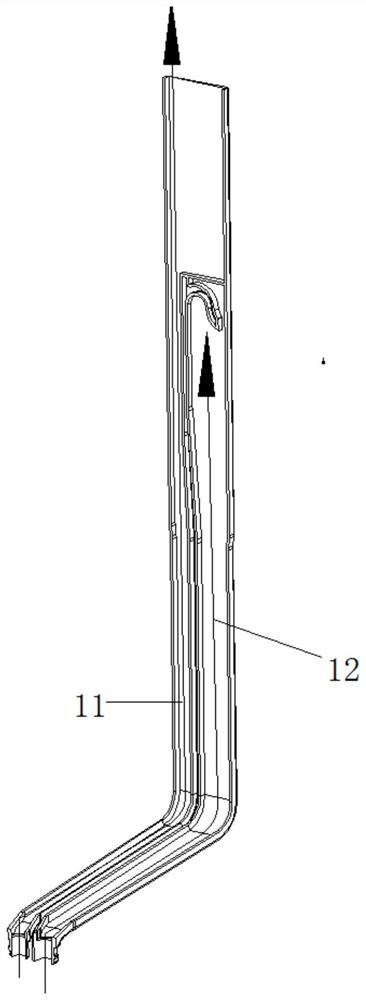

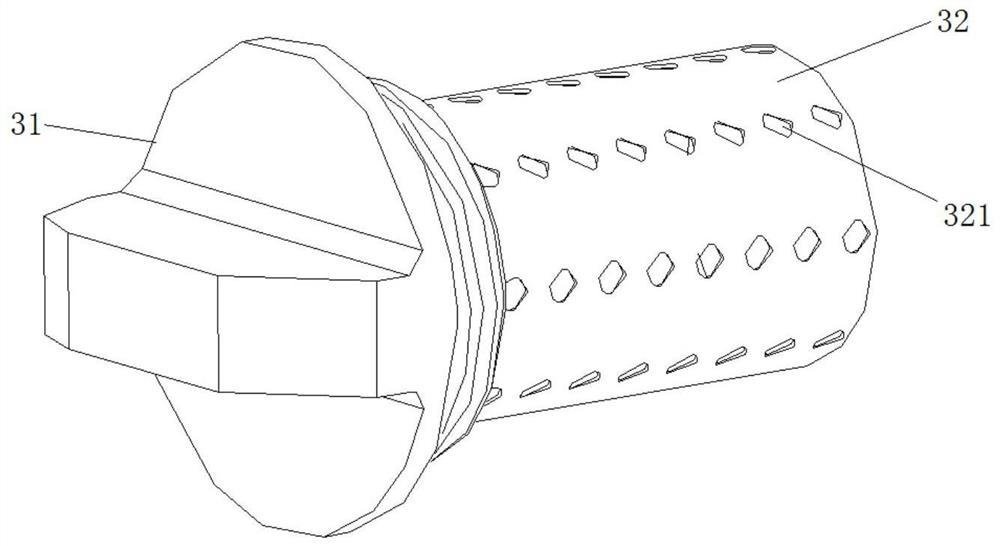

[0058] Such as Figure 1 to Figure 5 As shown, an electrolytic disinfection structure provided in this embodiment includes an electrolytic water circuit 11, which is suitable for being arranged on the inner container of a dishwasher; an electrolytic assembly 2, which includes a water inlet 21 communicating with the electrolytic water circuit 11; It is suitable for communicating with the water outlet 22 of the inner tank; and the electrolysis chamber 23 connected between the water inlet 21 and the water outlet 22, the electrolysis chamber 23 is provided with an electrode 231; Salt feeding device 3.

[0059] In this embodiment, by setting the electrolytic assembly in the inner tank of the dishwasher, the electrolytic water circuit 11 supplies water to the electrolytic assembly 2, and the salt feeding device 3 provides the reaction liquid required for the reaction to prepare the disinfection liquid, and the disinfection liquid flows into the water outlet into the liner to realiz...

Embodiment 2

[0075] This embodiment provides a dishwasher, which includes the electrolytic disinfection structure in Embodiment 1 above, and has all its technical advantages, which will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com