Preparation method and application of a biomass-based hydrothermal carbon-supported nano-aluminum catalyst

A technology of hydrothermal carbon and nano-aluminum, which is applied in the direction of catalyst activation/preparation, preparation of sugar derivatives, physical/chemical process catalysts, etc. It can solve the problems of enzymes that cannot be reused, low stability, and difficult to separate homogeneous systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

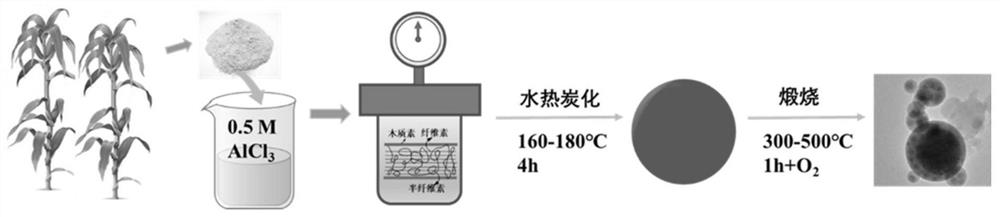

[0027] Such as figure 1 As shown, the preparation method and application of a kind of biomass-based hydrothermal charcoal supported nano-aluminum catalyst provided by the present invention comprises the following steps:

[0028] 1) The corn stalks are washed to remove dust, air-dried and crushed, and passed through a 40-mesh sieve.

[0029] 2) Add 20 g of corn stalk powder and 200 ml of 0.5 mol / L AlCl in a glass-lined reactor (4500, Parr Instrument Company, America) 3 Aqueous solution, the ratio of solid to liquid is 1:10 (g / ml). The reaction conditions were controlled by a Parr 4848 controller, and the stirring speed was 60r / min. Keep warm for 4 hours, and set three different hydrothermal carbonization temperatures of 160°C, 180°C and 200°C. After the reaction system was cooled to room temperature, the hydrothermal solid was vacuum filtered and washed, and then dried in an oven at 105° C. for 8 hours.

[0030] 3) The samples prepared at different hydrothermal temperatures...

Embodiment example 1

[0037] 1. Preparation of aluminum-containing hydrothermal carbon

[0038] Add 20 g of corn stover and 200 mL of 0.5 mol / L AlCl in a glass-lined reactor (4500, Parr Instrument Company, America) 3 Aqueous solution, the solid-to-liquid ratio is 1:10 (g / mL). Such as figure 1, using Parr 4848 controller to control the reaction conditions, stirring speed 60r / min. Keep warm for 4 hours, and set three different hydrothermal carbonization temperatures of 160°C, 180°C and 200°C. Two parallel experiments were performed for each group of samples. After the reaction system was cooled to room temperature, the hydrothermal solids were vacuum filtered and washed, and then dried in an oven at 105° C. for 8 hours to obtain aluminum-containing hydrothermal carbon solids. AlCl 3 The addition of the solution lowered the temperature of lignocellulose hydrothermal char formation.

Embodiment example 2

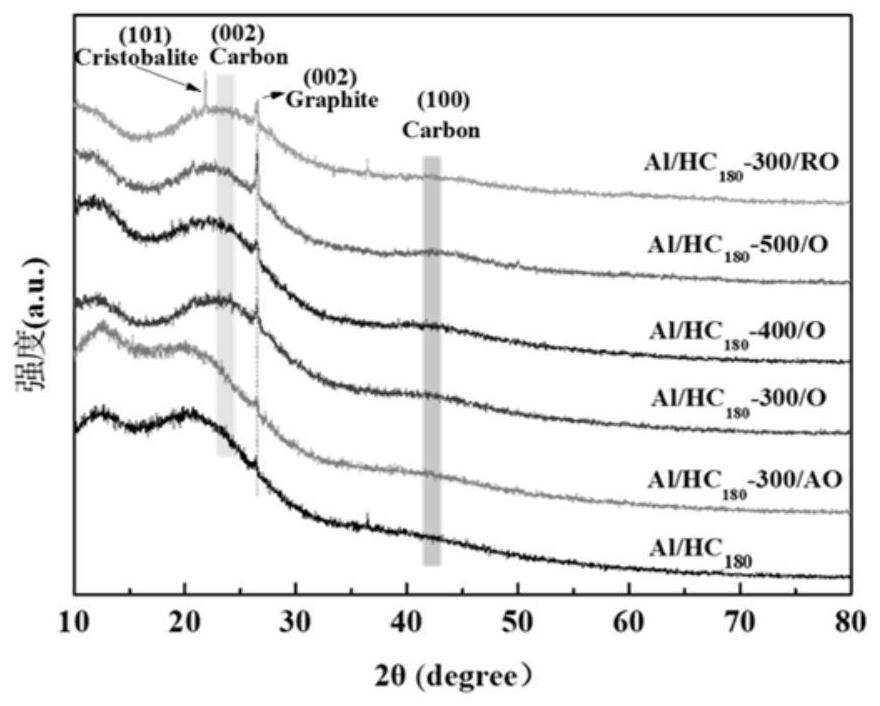

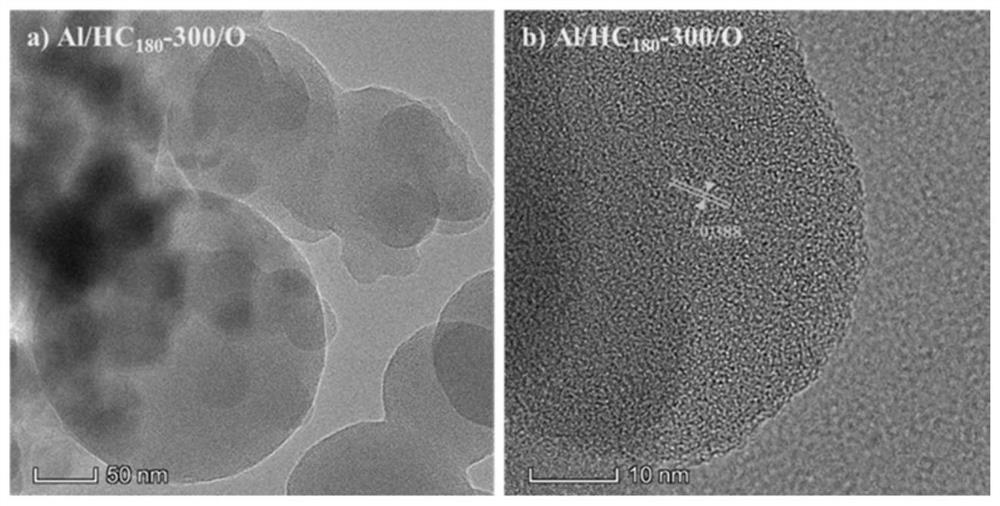

[0040] 2. Preparation of aluminum-supported hydrothermal carbon catalyst

[0041] The samples prepared above at different hydrothermal temperatures were calcined under anaerobic and anaerobic environments. The low-oxygen calcination is carried out in a muffle furnace. Weigh 1g of aluminum-containing hydrothermal charcoal solid into a 30mL porcelain crucible, cover it, fix it with a crucible shelf and place it in a muffle furnace for calcination for 1h. The heating rate is 5°C / min. Three different calcination temperatures 300°C, 400°C and 500°C. Anaerobic calcination was carried out in a tube furnace, and 1 g of hydrothermal charcoal was also weighed and placed in a rectangular corundum boat to calcine the sample (experimental conditions: temperature 300°C, 400°C and 500°C, heating rate 5°C / min, Holding time 1h, Ar flow rate is 120cm 3 / min), prepared as an aluminum-hydrothermal carbon catalyst, and the prepared catalyst was ground with an agate mortar. The Al-hydrothermal c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com