Preparation of a graphene-coated sulfur-intercalated ordered mesoporous carbon sphere composite and its application as a cathode material for lithium-sulfur batteries

A graphene-coated lithium-sulfur battery technology, applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of severe capacity attenuation, shuttle effect, and inability to meet the requirements of high-performance batteries, and achieve electrochemical performance Excellent, simple and efficient preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

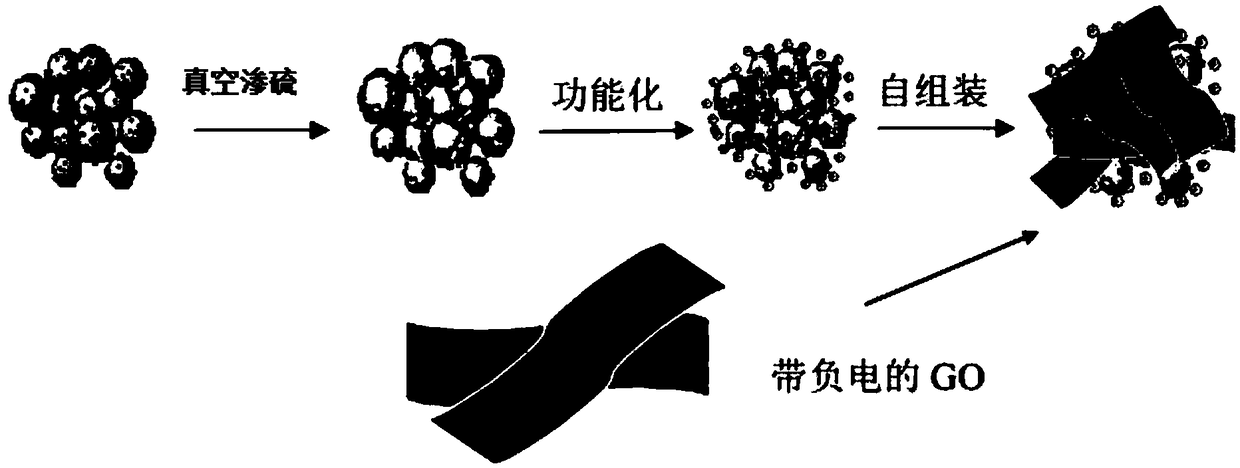

Method used

Image

Examples

Embodiment 1

[0044] First, add 5mL of concentrated sulfuric acid to 100mL of deionized water, heat to 38°C, add 4.0g of triblock copolymer F127 (polyoxyethylene-polyoxypropylene-polyoxyethylene), and after it is completely dissolved, add 2.0g of propane Triol and stirred for 2 hours, then added 8g of tetraethyl orthosilicate, continued to stir for 10 minutes, then stood at 38°C for 28 hours, reacted hydrothermally at 110°C in the reactor for 28 hours, filtered and washed, put it in an oven After drying at 115°C for 8 hours, the temperature was adjusted to 170°C for pre-carbonization for 5 hours to obtain a composite. Put the composite into a carbonization furnace and raise the temperature to 900°C at a rate of 2°C / min under the protection of a nitrogen atmosphere, stop heating after 3 hours of heat preservation and cool naturally, then soak in 15wt% hydrofluoric acid, and then wash, Drying and grinding yield ordered mesoporous carbon spheres.

[0045] Mix 1g of spherical ordered mesoporou...

Embodiment 2

[0056] First, add 2mL of concentrated sulfuric acid into 75mL of deionized water, heat to 36°C, add 2.0g of F127, after it is completely dissolved, add 2.0g of glycerol and stir for 1.5 hours, then add 6g of ethyl orthosilicate, continue Stir for 10 minutes, then stand at 36°C for 28 hours, hydrothermally crystallize in a reactor at 105°C for 26 hours, filter and wash, put in an oven and dry at 110°C for 7 hours, then adjust the temperature to 165°C for 4.5 hours to obtain Complex. Put the composite into a carbonization furnace and raise the temperature to 875°C at a rate of 2°C / min under the protection of a nitrogen atmosphere, stop heating after 2.5 hours of heat preservation and cool naturally, then soak with 15wt% hydrofluoric acid, and then wash, Drying and grinding yield ordered mesoporous carbon spheres.

[0057] Mix 1g of spherical ordered mesoporous carbon material with 1.5g of elemental sulfur, heat up to 800°C at a rate of 5°C / min under a vacuum of 10KPa, keep it w...

Embodiment 3

[0061] First, add 10mL of concentrated sulfuric acid to 125mL of deionized water, heat to 40°C, add 6.0g of F127, after it is completely dissolved, add 2.0g of glycerol and stir for 2.5 hours, then add 10g of ethyl orthosilicate, continue Stir for 10 minutes, then stand at 40°C for 28 hours, hydrothermally react in a reactor at 115°C for 30 hours, filter and wash, put in an oven and dry at 120°C for 9 hours, then adjust the temperature to 175°C for pre-carbonization for 5.5 hours to obtain a compound things. Put the compound into a carbonization furnace and raise the temperature to 975°C at a rate of 2°C / min under the protection of a nitrogen atmosphere, stop heating after 3.5 hours of heat preservation and cool naturally, then soak in 15wt% hydrofluoric acid, and then wash, Drying and grinding yield ordered mesoporous carbon spheres.

[0062] Mix 1g of spherical ordered mesoporous carbon material with 2.5g of elemental sulfur, heat up to 900°C at a rate of 5°C / min under a va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com