A kind of spherical graphite anode material with controllable morphology and preparation method thereof

A technology of spherical graphite and negative electrode materials, which is applied in the direction of negative electrodes, battery electrodes, and active material electrodes, can solve the problems of large differences in the shape of negative electrode materials, complex manufacturing processes of carbon microspheres, and difficulty in producing sample prices. High isotropy, improved processability, and enhanced electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

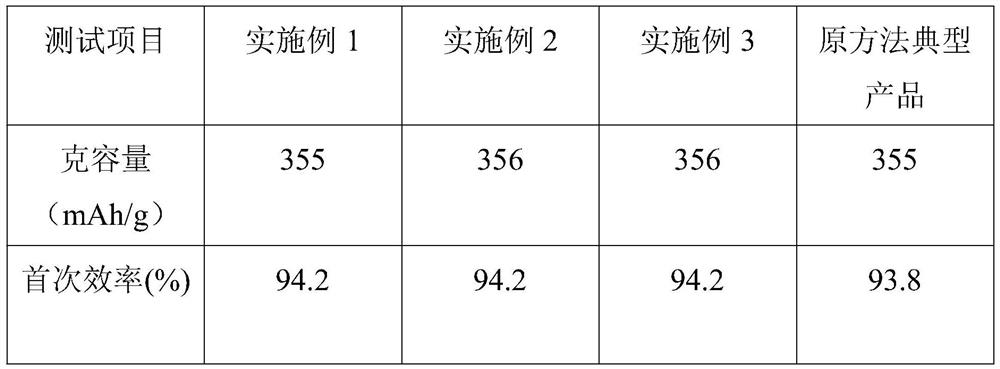

Embodiment 1

[0031] 1) Graphitization treatment: the graphite precursor is subjected to graphitization treatment, and the graphitization temperature is 3100° C. to obtain a graphite material.

[0032] 2) Mixing: Disperse the graphite material, dispersant, binder, and conductive agent in distilled water at a ratio of 97:1.5:0.5:1, stir for 3 hours, and adjust the viscosity of the slurry to 700 mPa*s and the solid content of 40 during this process. % to obtain a suitable mixed slurry.

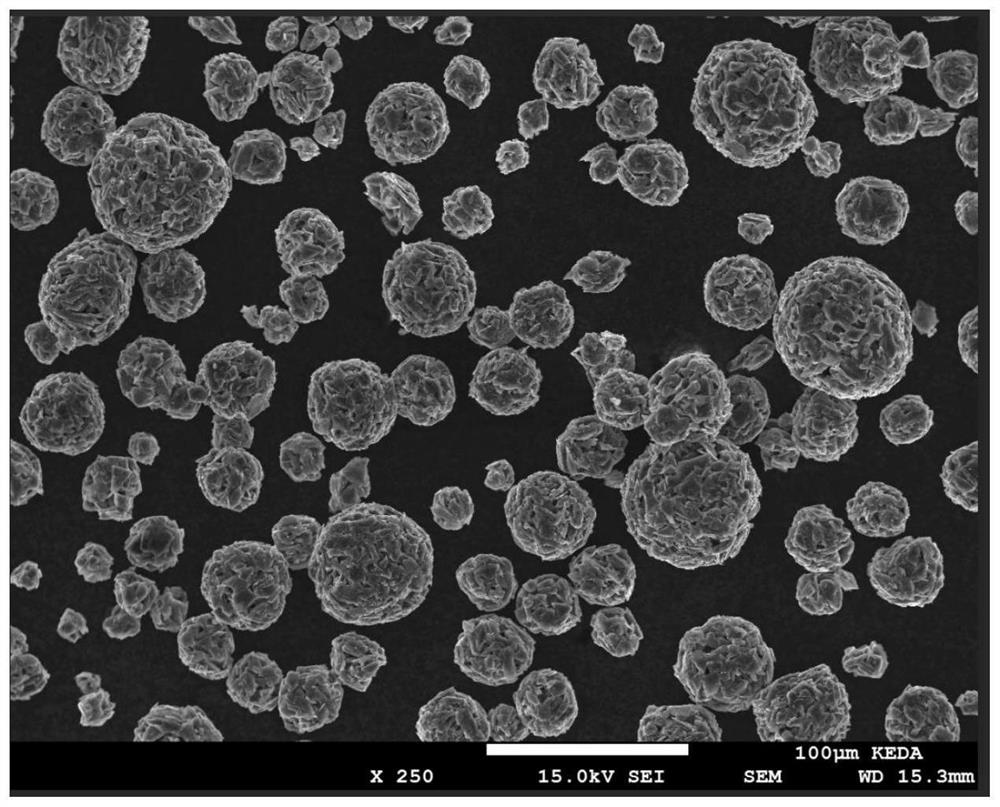

[0033] 3) Spheroidization: the slurry is dried into powder by spray drying equipment to obtain spherical granulated products. The inlet air temperature of spray drying is 200°C, the outlet air temperature is 100°C, and the atomizer frequency is 400Hz.

[0034] 4) Stability treatment: the surface of the spherical granulated product is coated with a dense single-layer metal thin layer of iron-copper alloy by vacuum sputtering coating method; the sputtering power of vacuum sputtering coating is 2000W, the ultra...

Embodiment 2

[0039] 1) Graphitization treatment: the graphite precursor is subjected to graphitization treatment, and the graphitization temperature is 3200° C. to obtain a graphite material;

[0040] 2) Mixing: Disperse the graphite material, dispersant, binder, and conductive agent in distilled water at a ratio of 97:1.5:0.5:1, stir for 3 hours, and adjust the viscosity of the slurry to 800mPa*s and the solid content of 38. % to obtain a suitable mixed slurry;

[0041] 3) Spheroidization: the slurry is dried into powder by spray drying equipment to obtain spherical granulated products. The inlet air temperature of spray drying is 210°C, the outlet air temperature is 100°C, and the atomizer frequency is 420Hz;

[0042] 4) Stability treatment: the surface of the spherical granulated product is coated with a dense single-layer metal thin layer of iron-copper alloy by vacuum sputtering coating method; the sputtering power of vacuum sputtering coating is 1800W, the ultrasonic vibration power...

Embodiment 3

[0047] 1) Graphitization treatment: the graphite precursor is subjected to graphitization treatment, and the graphitization temperature is 3200° C. to obtain a graphite material;

[0048] 2) Mixing: Disperse the graphite material, dispersant, binder and conductive agent in distilled water at a ratio of 97:1.5:0.5:1, stir for 3 hours, and adjust the viscosity of the slurry to 850mPa*s and the solid content of 36 during the process. % to obtain a suitable mixed slurry;

[0049] 3) Spheroidization: the slurry is dried into powder by spray drying equipment to obtain spherical granulated products. The inlet air temperature of spray drying is 220°C, the outlet air temperature is 100°C, and the atomizer frequency is 430Hz;

[0050] 4) Stability treatment: the surface of the spherical granulated product is coated with a dense single-layer metal thin layer of iron-copper alloy by vacuum sputtering coating method; the sputtering power of vacuum sputtering coating is 1600W, the ultrasonic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com