Welding, feeding and conveying device for automatic production of electric water heater heating disc

A technology for electric water heaters and conveying devices, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve problems such as welding errors, difficulty in separating a single insert, and difficulty in fixing the shape of the heating tube, so as to ensure symmetry and improve clamping effect of tightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

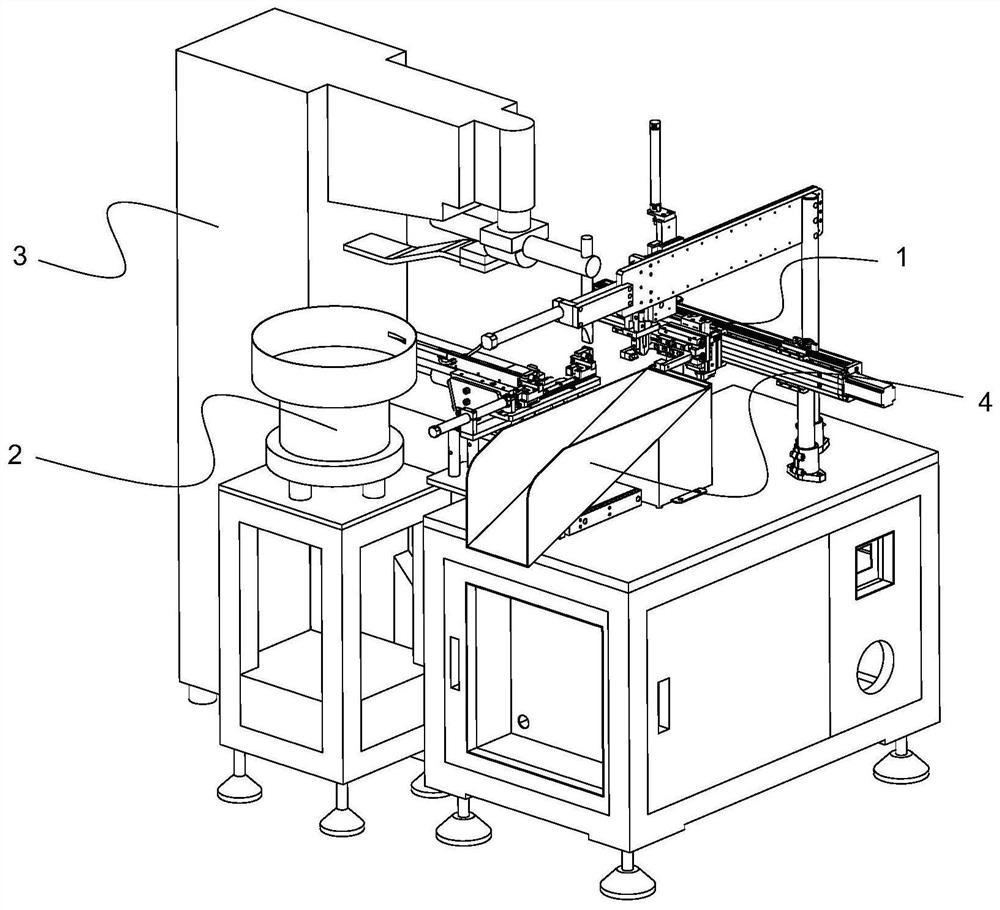

[0023] Such as figure 1 As shown, a heating plate wire connection plate welding equipment for an electric water heater, the equipment includes a frame and a heating plate welding feeding and conveying device 1 installed on the frame, an insert feeding device 2, a welding device 3 and a discharge track 4 The end of the heating plate welding feeding conveying device 1 is connected to the welding device 3, and the discharge end of the insert feeding device 2 is connected to the welding device 3; the discharge track 4 is located on one side of the insert feeding device 2, The feeding end of the material track 4 is connected with the middle part of the heating plate welding feeding conveying device 1; the heating plate welding feeding conveying device 1 is used for feeding the heating plate, fixing the heating plate during welding, and heating the heating plate after welding. sent to the discharge track 4; the insert feeding device 2 is used to transport the insert to the conductiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com