Battery cover assembly system, adsorption jig and assembly method

A technology for assembling system and battery cover, applied in the field of parts assembly, can solve the problem of edge-finding and positioning deviation between the battery cover and the middle frame, and achieve the effect of avoiding springback and improving the accuracy of edge-finding positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Exemplary embodiments will be described in detail herein, examples of which are illustrated in the accompanying drawings. The following description refers to

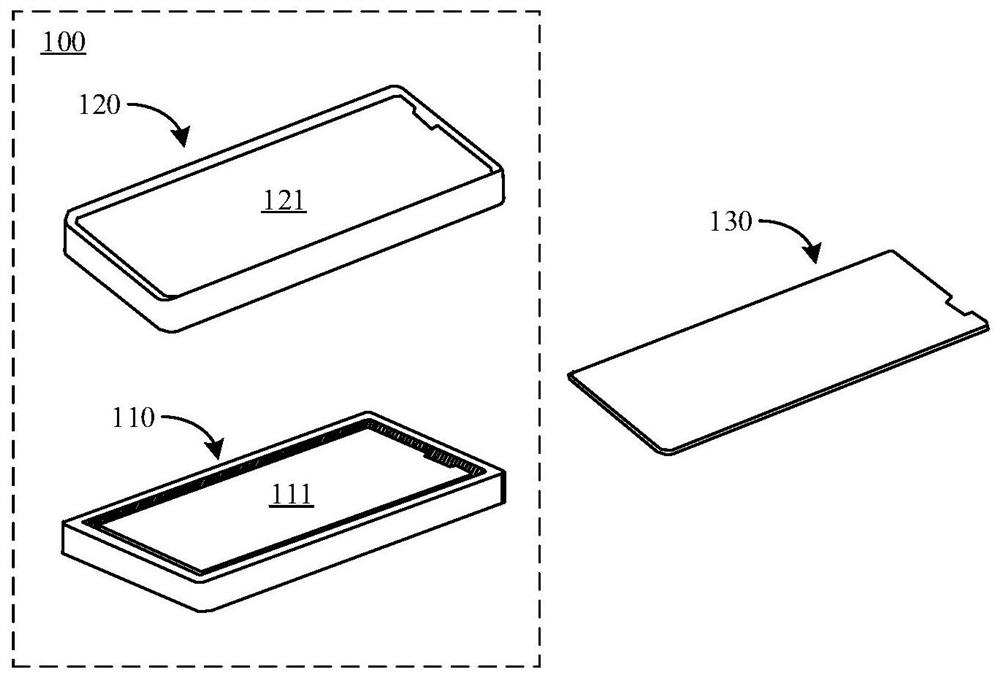

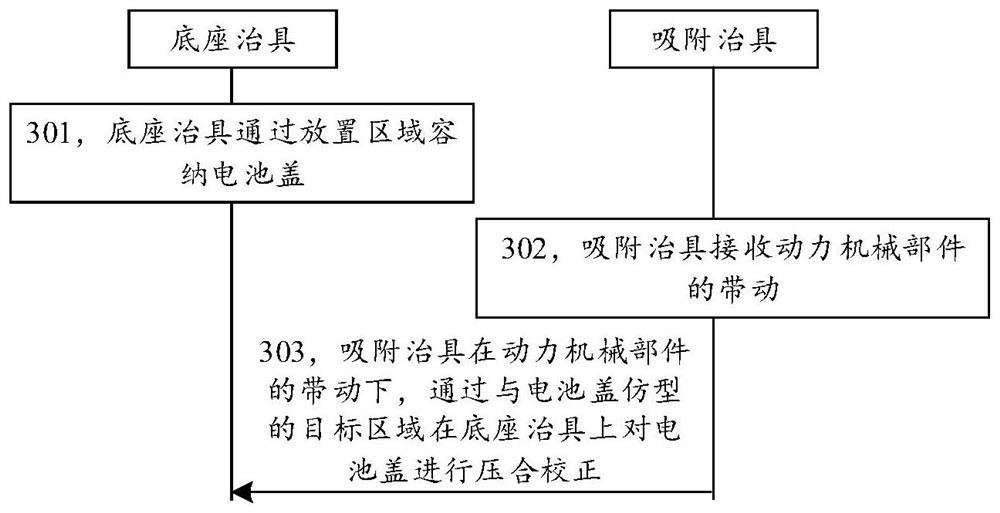

[0059] FIG. 1 is a structural diagram of an assembly system for a battery cover provided by an exemplary embodiment of the present disclosure, as shown in FIG. 1 ,

[0062] Optionally, the base fixture 110 and the adsorption fixture 120 are two fixtures that have been positioned and calibrated.

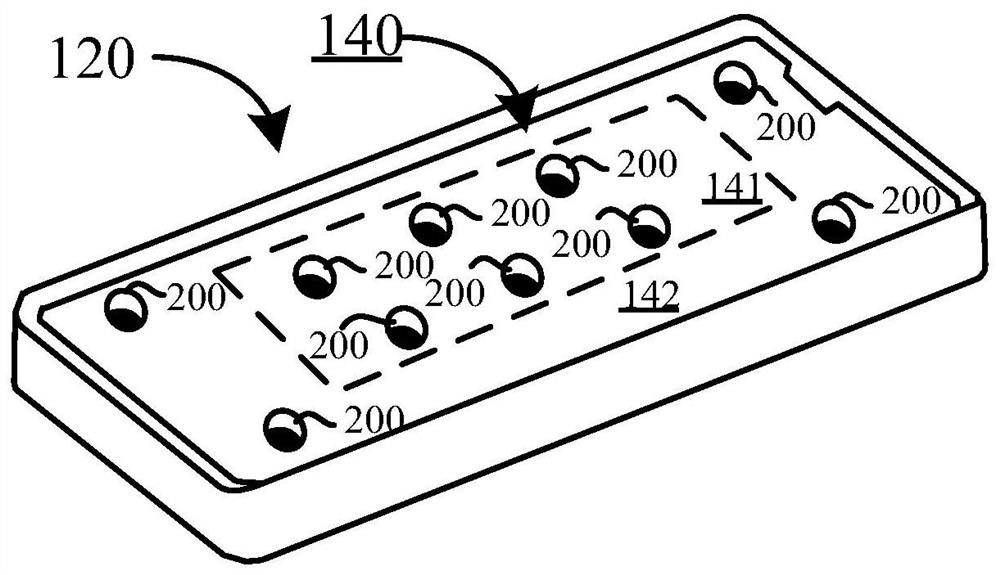

[0063] Optionally, the above-mentioned adsorption area 140 and the target area 121 can be implemented as the same area, or an adsorption area

[0064] To sum up, the assembly system of the battery cover provided in the embodiment of the present disclosure, the battery cover is

[0065] The assembly system provided by this embodiment, the battery cover is taken from the base jig in an adsorption manner by an adsorption jig.

[0066] In an optional embodiment, the above-mentioned adsorption fixture 120 carries out the battery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com