Shielding cover

A technology of shielding cover and shielding frame is applied in the field of shielding cover, which can solve the problems of high mold development cost and mold repair cost, difficult disassembly, etc., so as to save mold development cost and mold repair cost, and reduce mold process, size and flatness. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

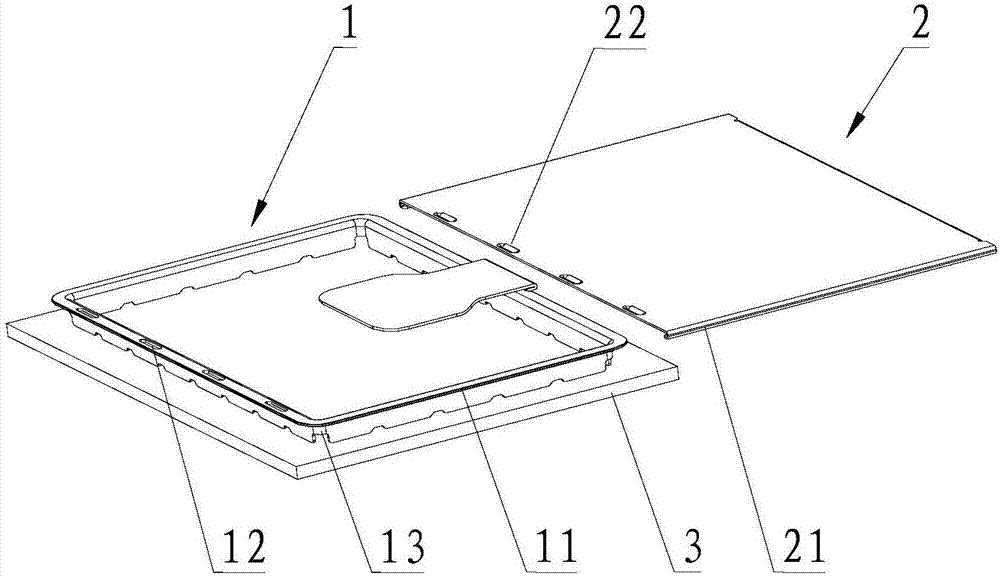

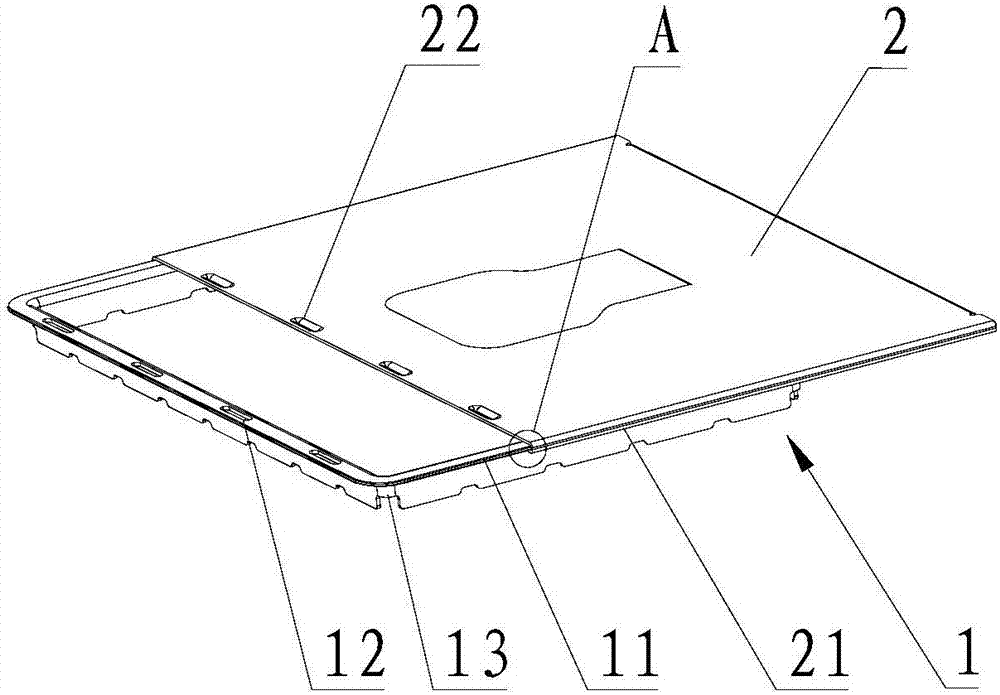

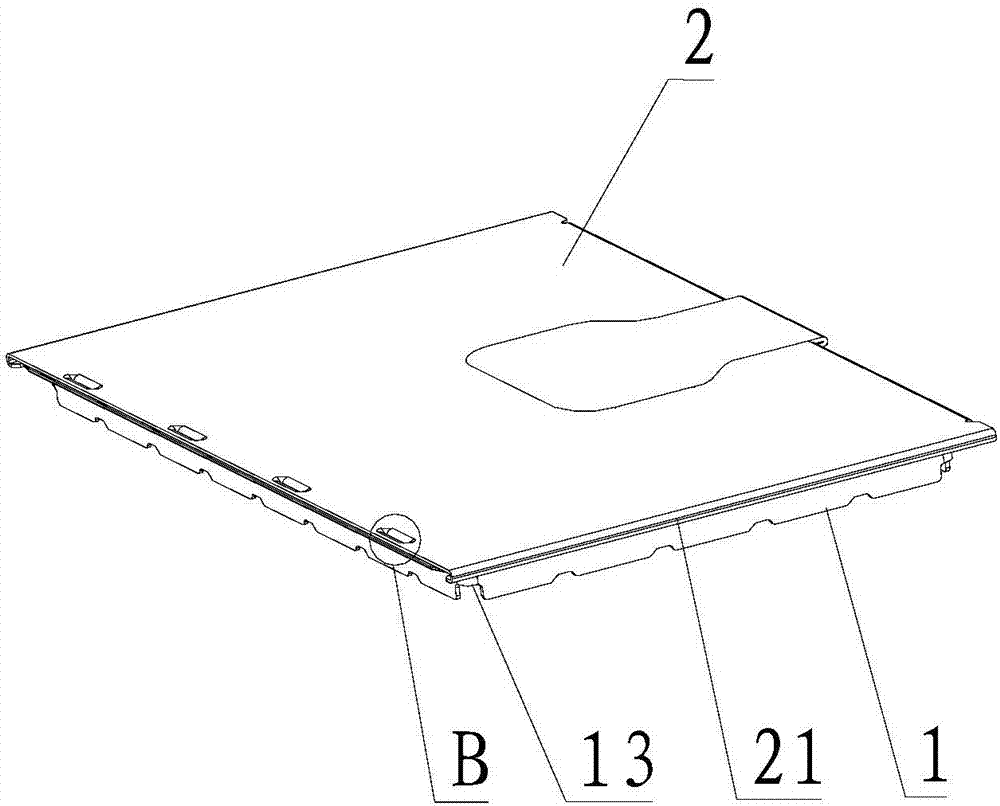

[0051] Please refer to Figure 1-5 , Embodiment 1 of the present invention is:

[0052] The shielding case of the present embodiment comprises a shielding frame 1, a shielding cover 2, a semi-stretched structure 13 and a plate-shaped PCB3, the shielding frame 1 is located on the PCB3, and the shielding frame 1 includes a first frame body, a second frame body, the third frame body and the fourth frame body, the first frame body, the second frame body, the third frame body and the fourth frame body respectively include a top surface and a side surface connected with the top surface, and the first frame body The top surfaces of the frame body, the second frame body, the third frame body and the fourth frame body are integrally formed, and the sides of the first frame body, the second frame body, the third frame body and the fourth frame body pass through The semi-tensile structures 13 are connected. The edge positions of the top surfaces of the first frame body and the third fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com