Large-size silicon wafer double-sided polishing method

A double-sided polishing and large-size technology, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, grinding machines, etc., can solve the problems of low polishing efficiency, poor consistency, and poor polishing effect, and achieve good cleaning effect and polishing Good effect and stable geometric parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

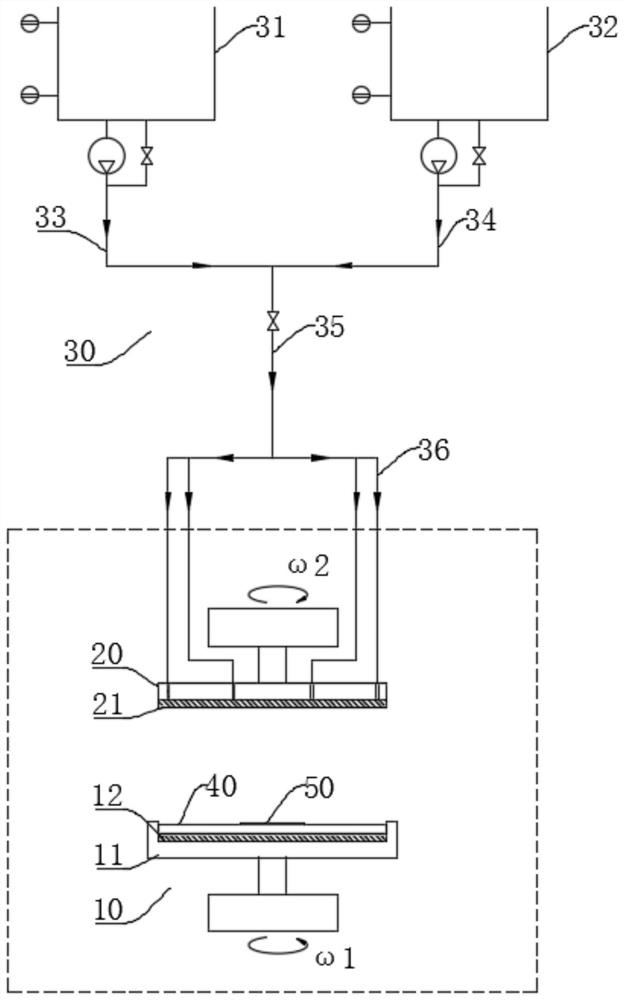

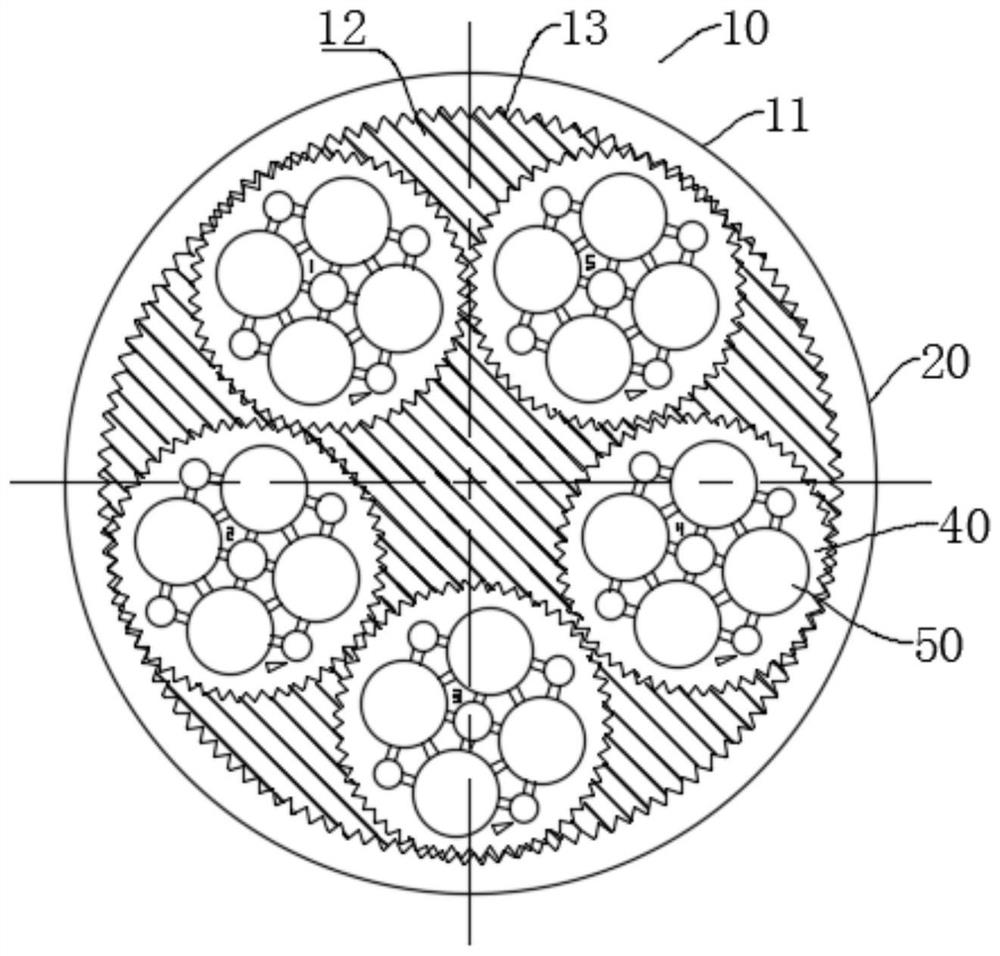

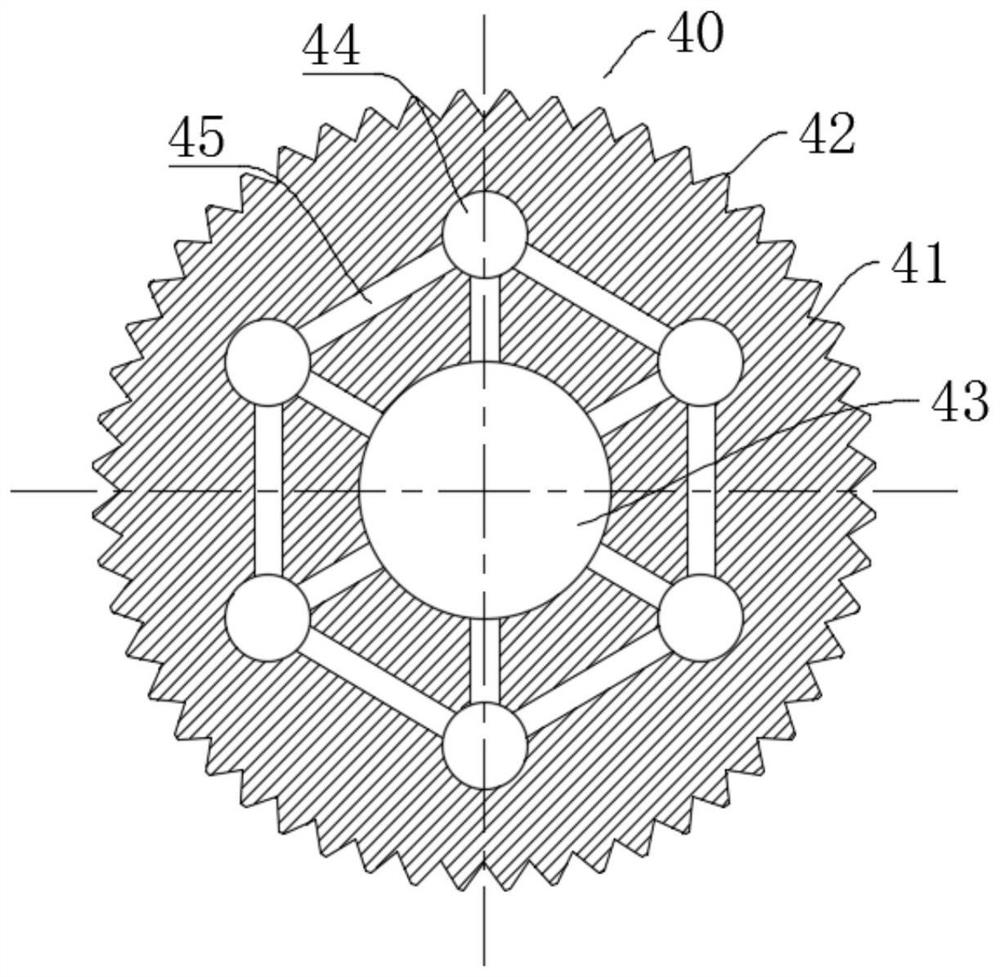

[0037] This embodiment proposes a double-sided polishing device for large-size silicon wafers, such as figure 1 As shown, it includes a carrier assembly 10 for placing a silicon wafer 50, a pressure plate 20 adapted to the carrier assembly 10 and in contact with the upper end surface of the silicon wafer 50, and a liquid casting assembly 30 that can provide rough or fine liquid. Single or several silicon wafers 50 are placed in the carrier assembly 10; the liquid throwing assembly 30 provides rough or fine throwing liquid to both sides of the silicon wafer 50 through the pressure plate 20, and the rough or fine throwing liquid is carried by the carrying assembly 10 and The counter-rotating force of the pressure plate 20 drives and rotates with the rotation of the silicon wafer 50 to polish both sides of the silicon wafer 50 .

[0038] Such a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com