Regenerated polyolefin plastic composition as well as preparation method and application thereof

A plastic composition and recycled polypropylene technology, which is applied in the field of engineering plastics, can solve the problems of poor toughness, poor stability, and low strength of waste polyolefin materials, and achieve the effects of improving toughness, increasing tensile strength, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

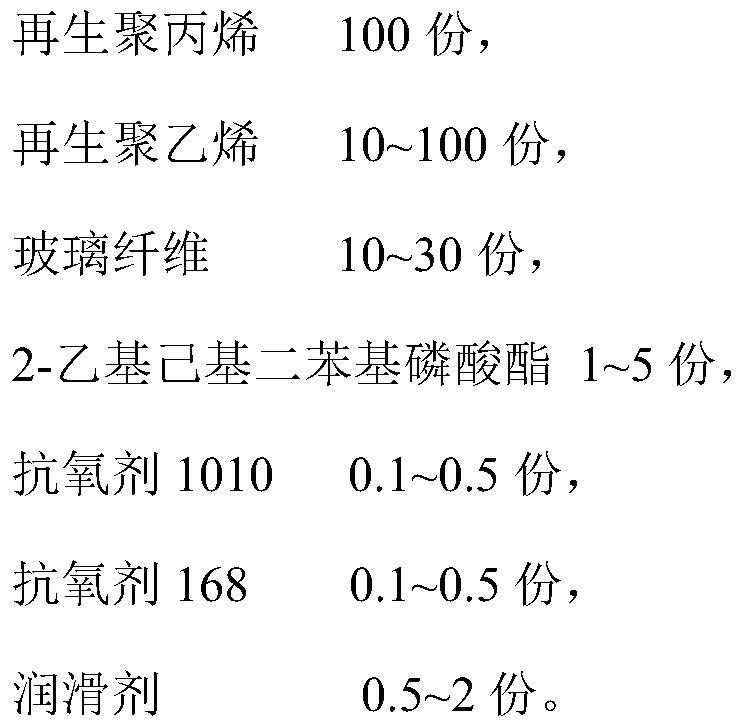

Method used

Image

Examples

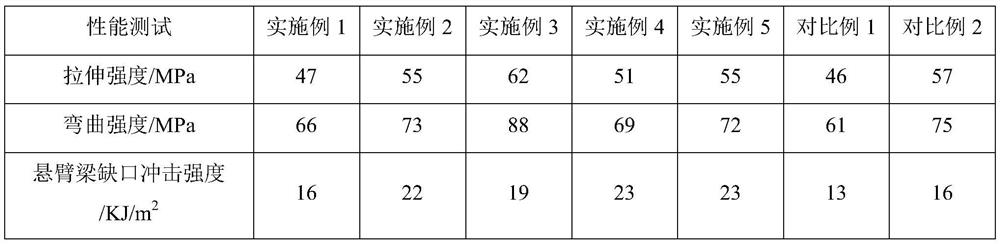

Embodiment 1

[0026] Pour 100 parts of recycled polypropylene, 10 parts of recycled polyethylene, 1 part of 2-ethylhexyl diphenyl phosphate, 0.1 part of antioxidant 1010, and 0.1 part of antioxidant 168 into a high-speed mixer according to parts by weight. The temperature is controlled at 20°C, the rotation speed is 1000r / min, and the mixing time is 3min; after turning on the mixer, add 0.5 parts of white oil, and mix again, the rotation speed is 300r / min, and the mixing time is 1min, so that it is fully uniform and the mixed material is obtained;

[0027] Feed the mixed material into the twin-screw extruder through the main feeding port, add 10 parts of glass fiber through the side feeding port, extrude, water-cool, pelletize and dry to obtain the recycled polyolefin plastic composition. Among them, the temperature of the twin-screw extruder is set as: 140°C in zone 1, 150°C in zone 2, 185°C in zone 3, 200°C in zone 4, 190°C in zone 5, 190°C in zone 6, and the rotation speed is 500 rpm.

Embodiment 2

[0029] Pour 100 parts of recycled polypropylene, 30 parts of recycled polyethylene, 5 parts of 2-ethylhexyl diphenyl phosphate, 0.2 part of antioxidant 1010, and 0.5 part of antioxidant 168 into a high-speed mixer according to parts by weight. The temperature is controlled at 40°C, the speed is 2000r / min, and the mixing time is 5 minutes; after turning on the mixer, add 2 parts of white oil, and mix again, the speed is 500r / min, and the mixing time is 2 minutes, so that it is fully uniform and the mixed material is obtained;

[0030] Feed the mixed material into the twin-screw extruder through the main feeding port, add 18 parts of glass fiber through the side feeding port, extrude, water-cool, pelletize and dry to obtain the recycled polyolefin plastic composition. Wherein the twin-screw extruder temperature is set as: zone 1 150°C, zone 2 160°C, zone 3 195°C, zone 4 210°C, zone 5 195°C, zone 6 200°C, and the speed is 1000 rpm.

Embodiment 3

[0032] Pour 100 parts of regenerated polypropylene, 50 parts of regenerated polyethylene, 3 parts of 2-ethylhexyl diphenyl phosphate, 0.4 part of antioxidant 1010, and 0.2 part of antioxidant 168 into a high-speed mixer according to parts by weight. The temperature is controlled at 30°C, the rotation speed is 1500r / min, and the mixing time is 4min; after turning on the mixer, add 1 part of white oil, and mix again, the rotation speed is 400r / min, and the mixing time is 1min, so that it is fully uniform and the mixed material is obtained;

[0033] Feed the mixed material into the twin-screw extruder through the main feeding port, add 30 parts of glass fiber through the side feeding port, extrude, water-cool, pelletize and dry to obtain the recycled polyolefin plastic composition. Among them, the temperature of the twin-screw extruder is set as: 145°C in the first zone, 155°C in the second zone, 190°C in the third zone, 205°C in the fourth zone, 190°C in the fifth zone, 195°C in ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap