A gearbox intermediate shaft structure

A gearbox and intermediate shaft technology, applied in gear lubrication/cooling, belt/chain/gear, transmission parts, etc., can solve the problems of low NHV index, improve accuracy, shorten axial dimension, and improve loadability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

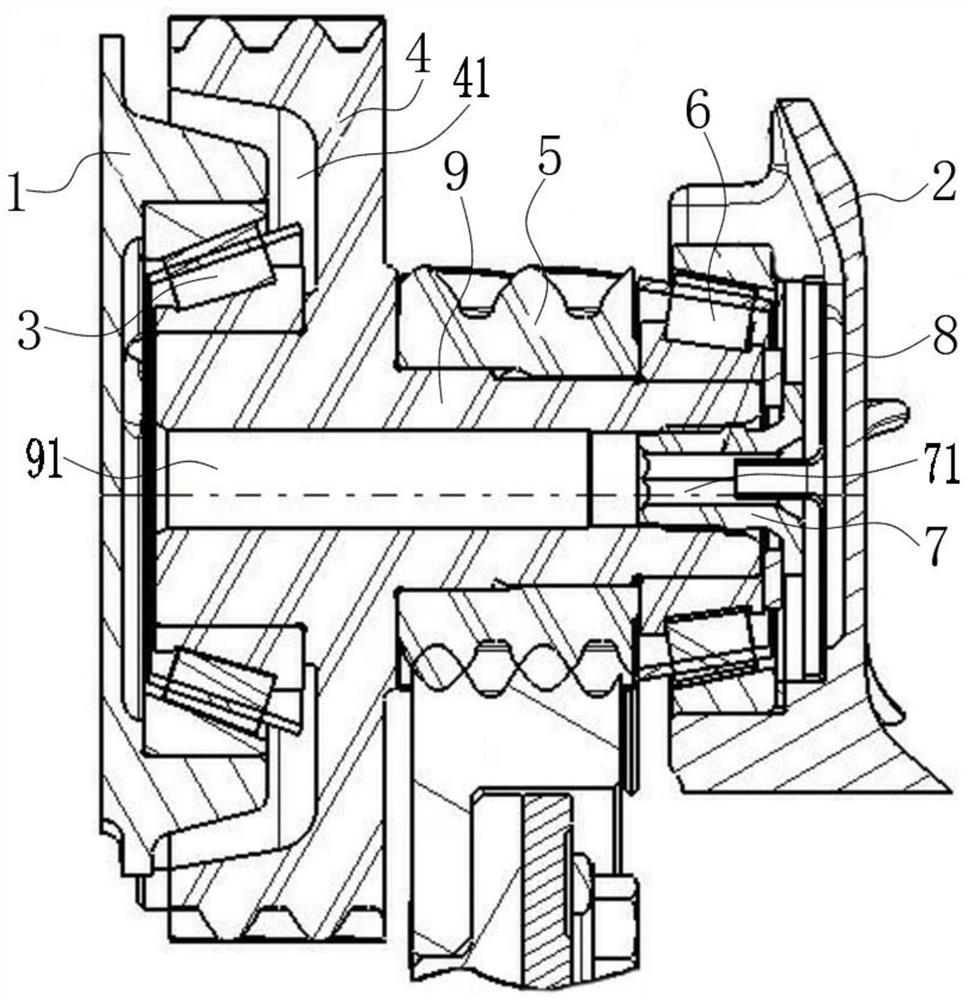

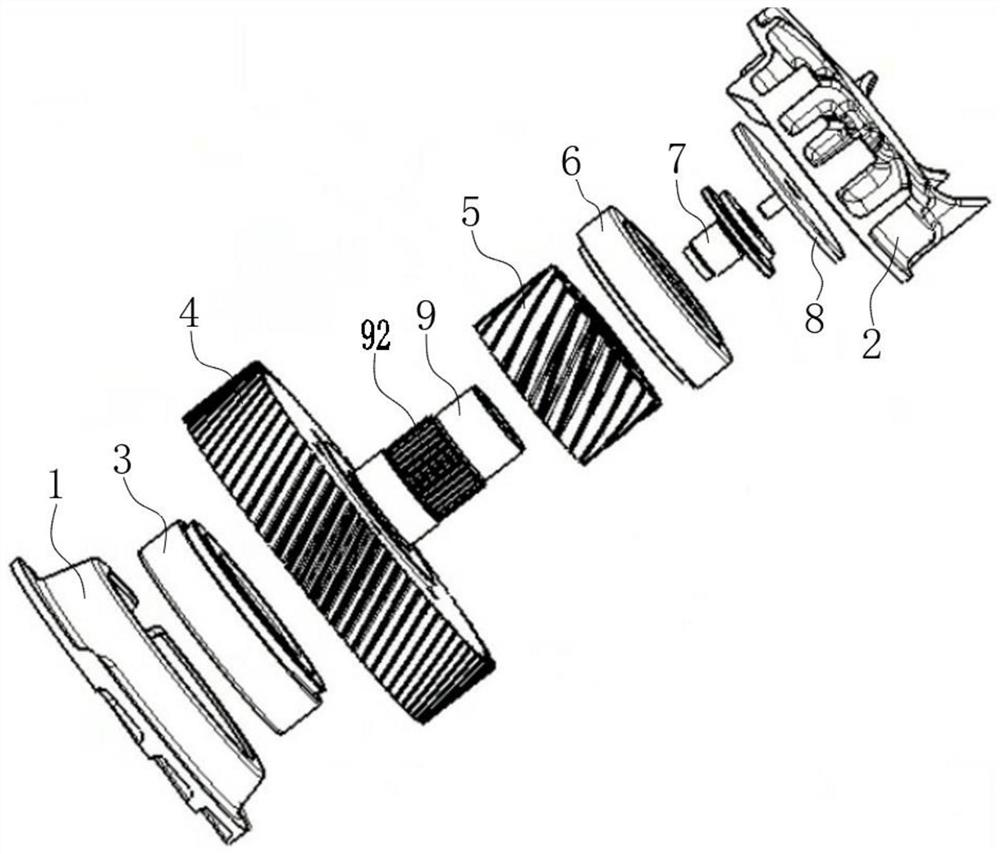

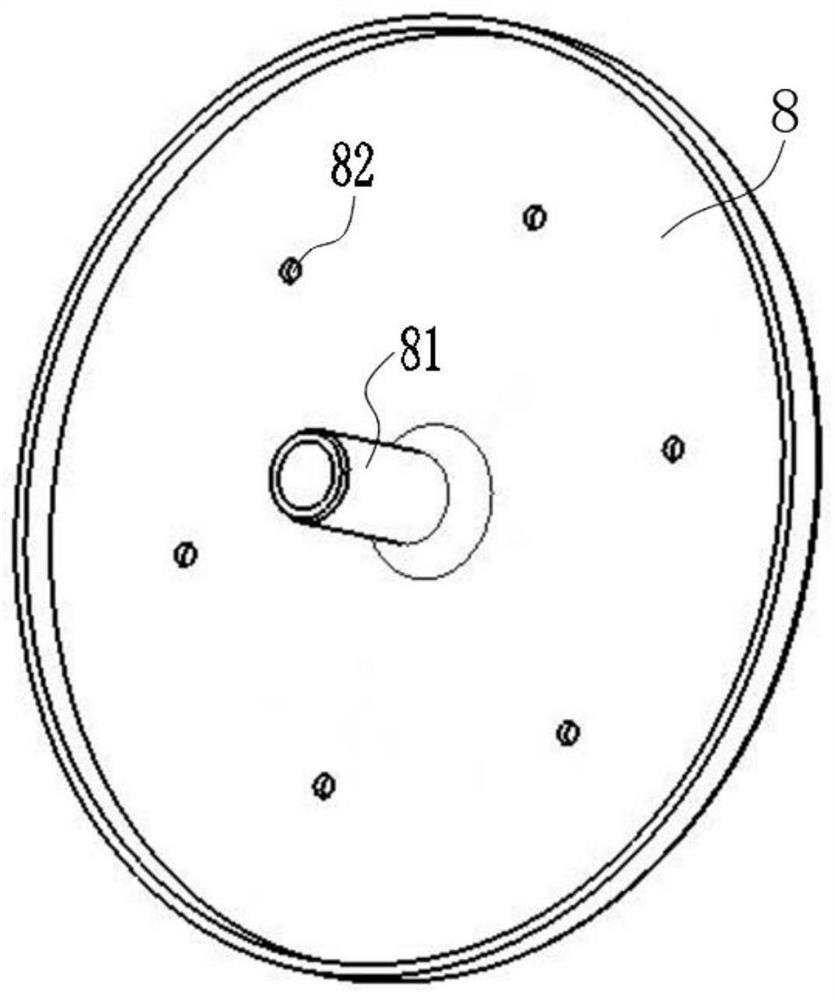

[0032] The present invention provides a gearbox intermediate shaft structure, such as Figure 1 to Figure 3 As shown, it includes a gearbox housing, a first bearing 3 , a first gear 4 , a second gear 5 , a second bearing 6 , a nut 7 , an oil guide 8 and a shaft body 9 . The shaft body 9 is provided with an axially penetrating cavity 91 for guiding the flow of lubricating oil. The first gear 4 and the second gear 5 are arranged on the outer side wall of the shaft body 9 , and the first gear 4 and the shaft body 9 are integrally formed. The outer side wall of the shaft body 9 is provided with external splines, the second gear 5 is provided with internal splines, and the second gear 5 slides along the splines 92 to be close to the first gear 4 .

[0033] like Figure 1 to Figure 3 As shown, a first bearing 3 on one side of the first gear 4 is connected between the shaft body 9 and the gearbox housing, and the first bearing 3 can make the first gear 4 rotate relative to the gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com