Method of gravity self-pressurization anti-segregation pumping high sand rate ready-mixed mortar

A ready-mixed mortar and anti-segregation technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems that affect the popularization and application of ready-mixed mortar, the high sand content of ready-mixed mortar, and the high sand content of dry-mixed mortar. To avoid the problem of mortar segregation, improve the quality of the project and shorten the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

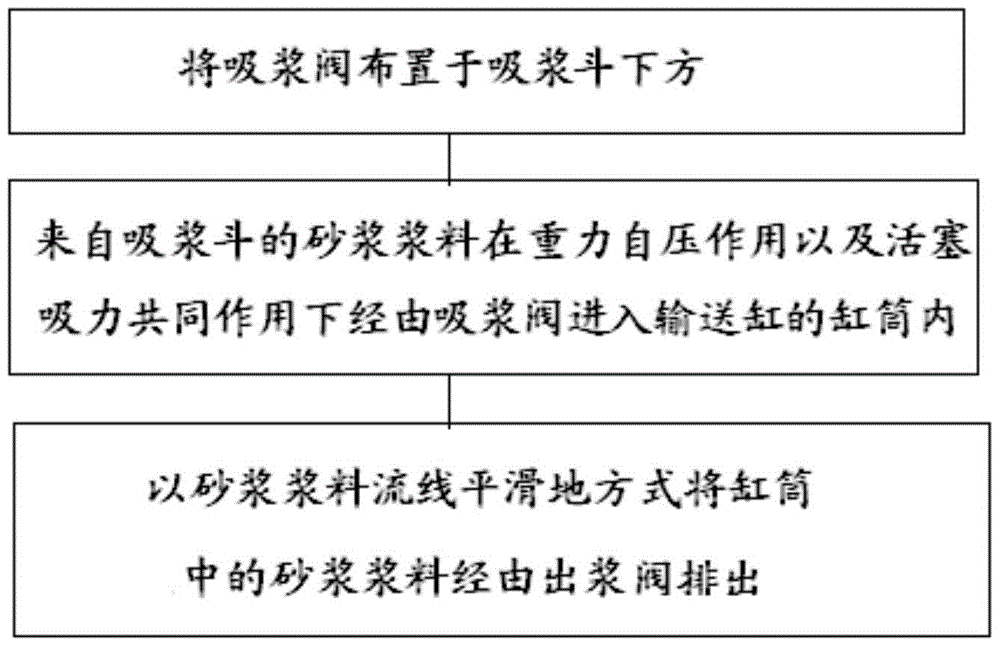

[0022] see figure 1 , The invention provides a flow chart of a method for pumping ready-mixed mortar with high sand ratio by gravity self-pressure anti-segregation pumping. The method of gravity self-pressure anti-segregation pumping high sand rate ready-mixed mortar preferably includes the following steps:

[0023] Arrange the slurry suction valve under the slurry suction hopper;

[0024] The mortar slurry from the slurry suction hopper enters the cylinder barrel of the delivery cylinder through the slurry suction valve under the combined action of gravity self-pressure and piston suction;

[0025] Smoothly discharge the mortar slurry in the cylinder through the slurry discharge valve along the flow line direction of the mortar slurry, wherein the slurry discharge valve is in the same direction as the delivery cylinder, and the discharge direction of the mortar slurry is straight out, and the flow direction basically does not change.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com