Patents

Literature

52results about How to "Smooth pumping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

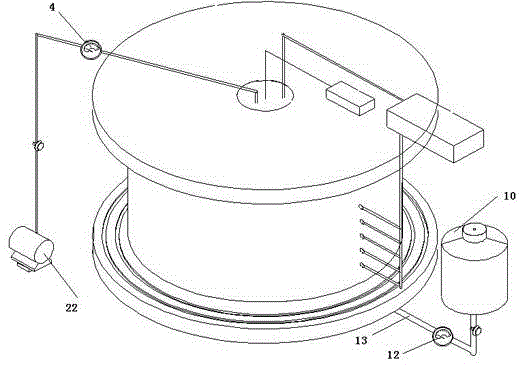

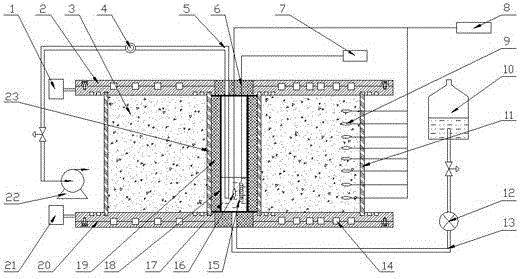

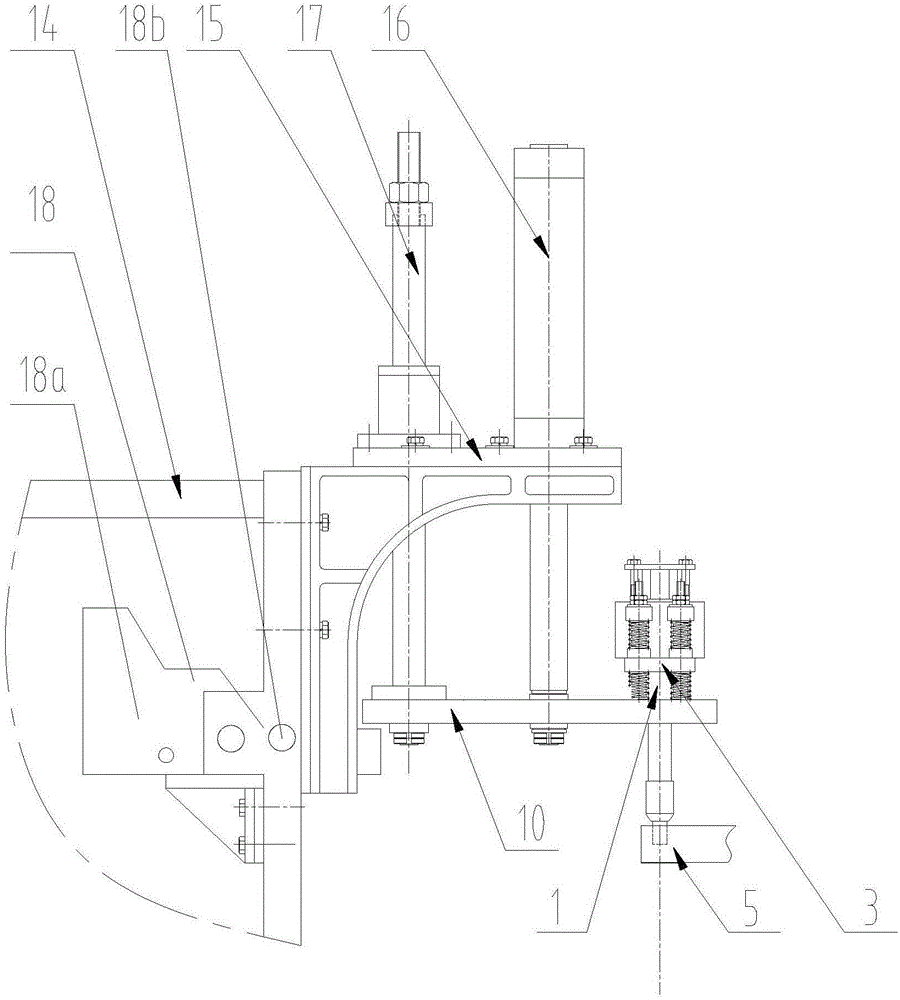

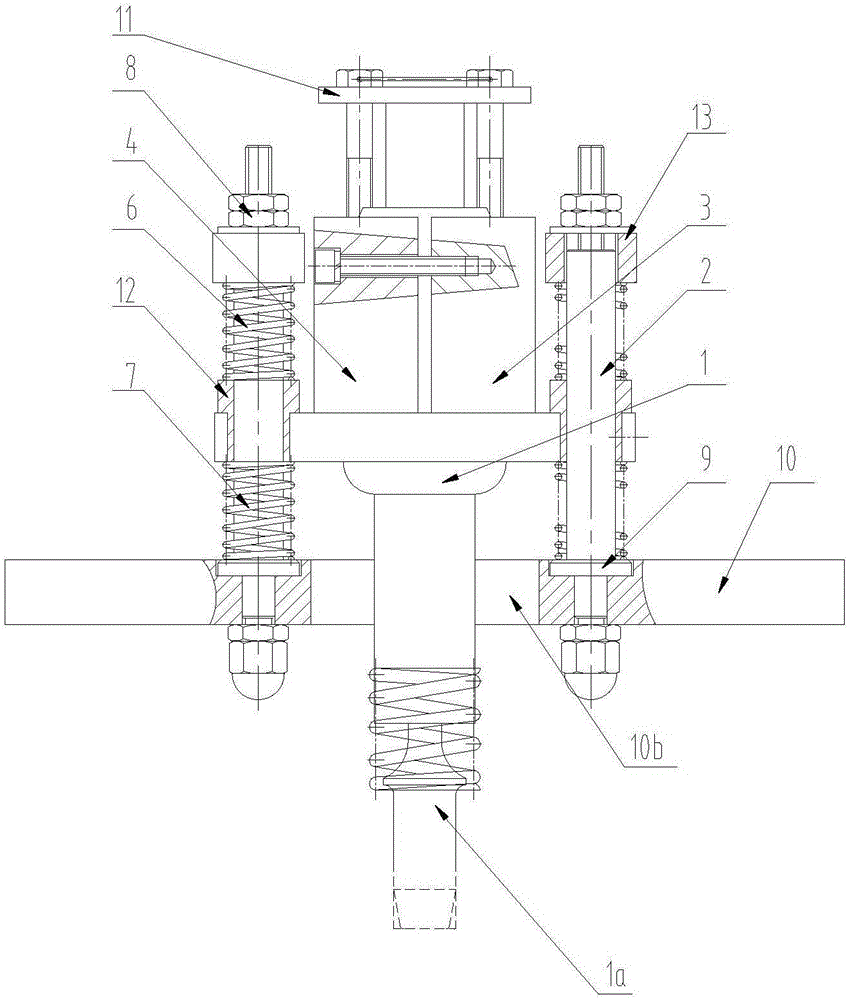

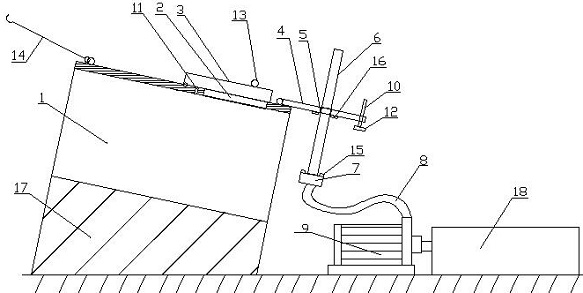

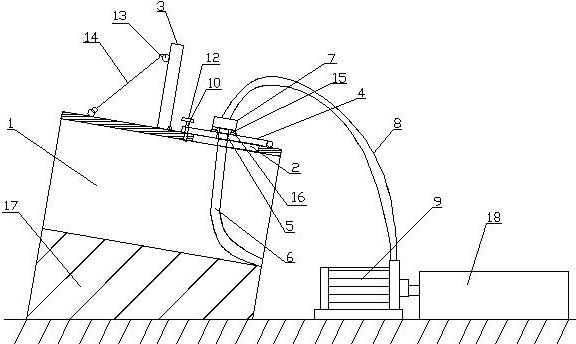

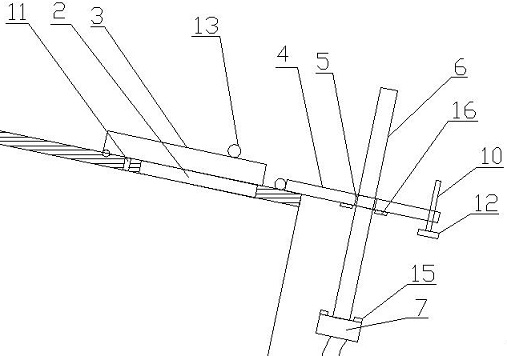

Test device for simulating permafrost region well heat insulation or heating

InactiveCN102864793AFlexible simulationReduce consumptionFoundation testingProtective foundationTemperature controlThermal insulation

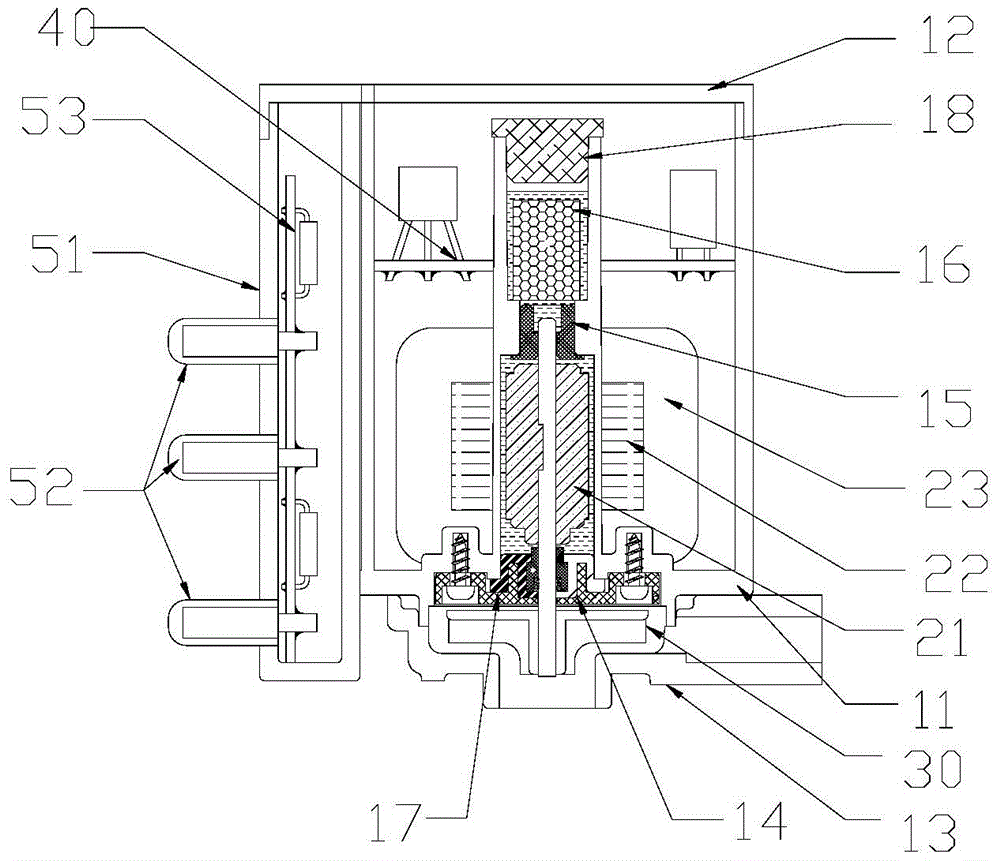

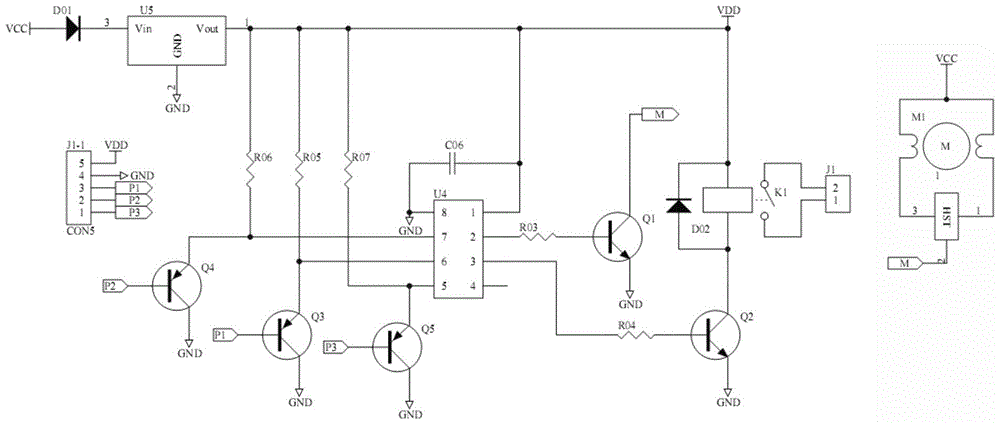

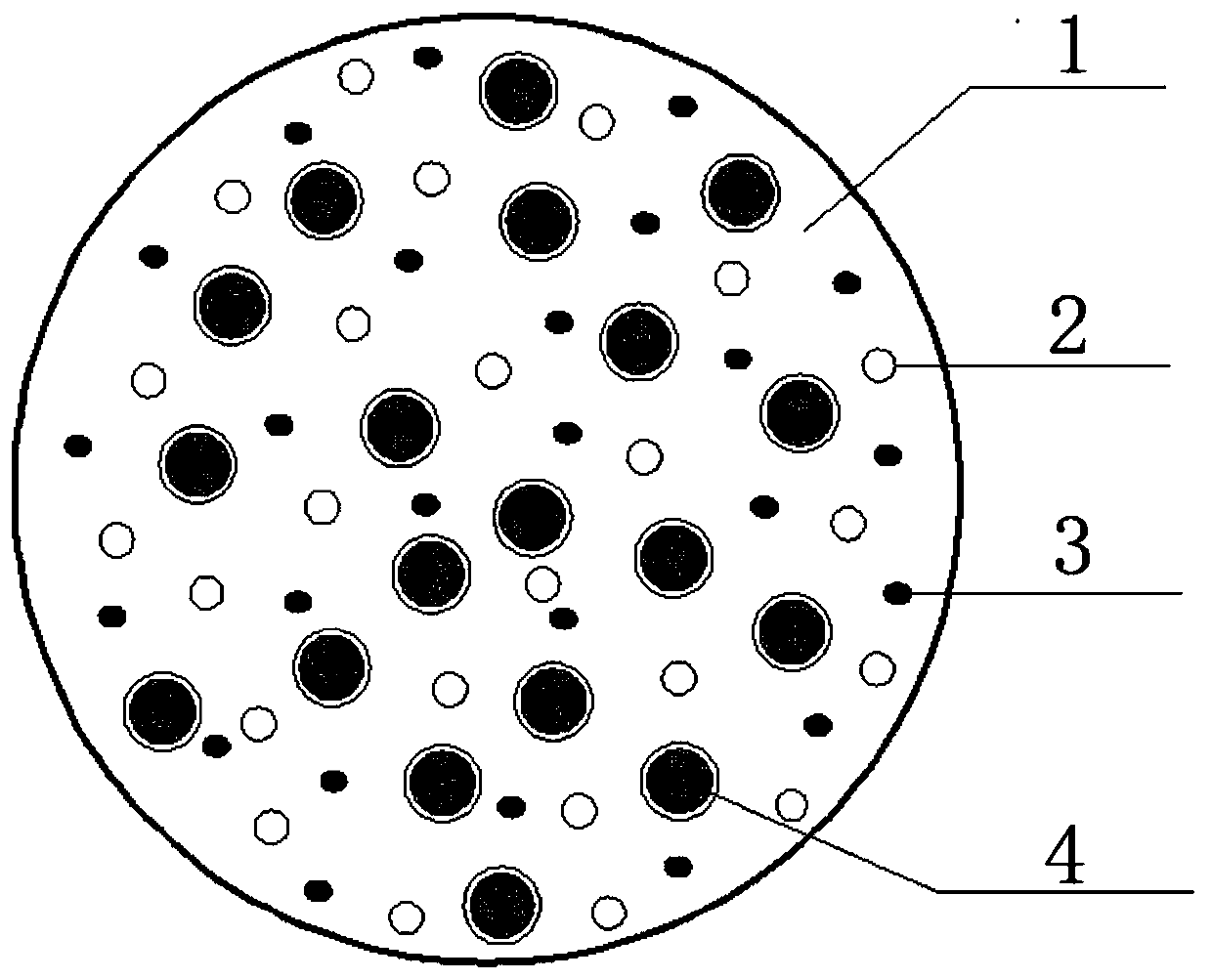

The invention relates to a test device for simulating permafrost region well heat insulation or heating. The test device is characterized in that a test tank is a circular interlayer barrel body consisting of an outer ring, an inner ring, a top plate and a bottom plate, a soil body is filled in an interlayer, a refrigerating liquid circulation passage is arranged inside the top plate and the bottom plate, is connected with a refrigerating temperature control device and is in contact with the soil body, water is filled in a water tank, the water tank is arranged in the test tank, a heat insulation barrel is placed between the water tank and the test tank, heat insulation covers are placed on and under the water tank, a water replenishing device is connected with a water tank bottom plate through a water replenishing pipe, a water pressure gauge is arranged on the water replenishing pipe, a water pumping device is connected with a water tank top cover through a water pumping pipe, the water pumping pipe is inserted into water of the water tank, a flow meter is arranged on the water pumping pipe, a heating temperature control device is connected with a heating pipe through a conducing wire, the heating pipe is inserted into the water of the water tank, and temperature sensors are arranged in the solid body and the water of the water tank and are respectively connected with a digital collecting instrument. The test device has the advantages that the permafrost region well is simulated, the reasonable well diameter, the water pumping speed, the heat insulation thickness and the power of a heating device are obtained, and the goals of energy saving and environment protection are reached.

Owner:COLD & ARID REGIONS ENVIRONMENTAL & ENG RES INST CHINESE

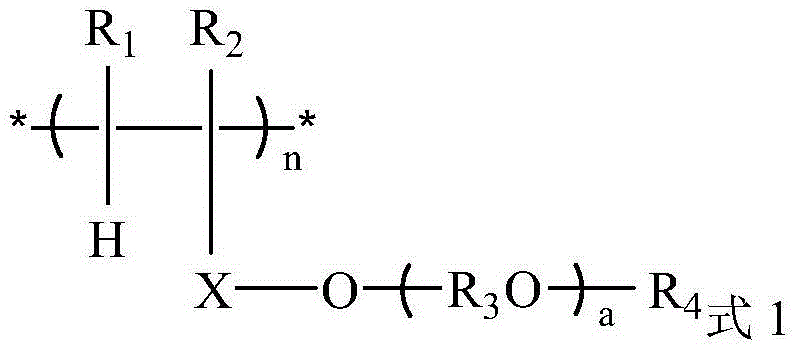

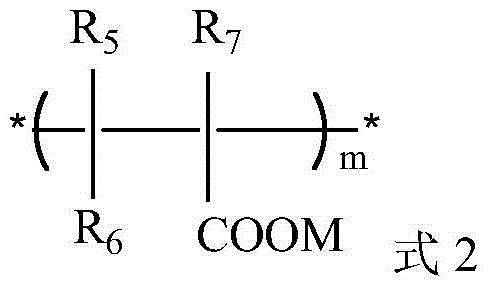

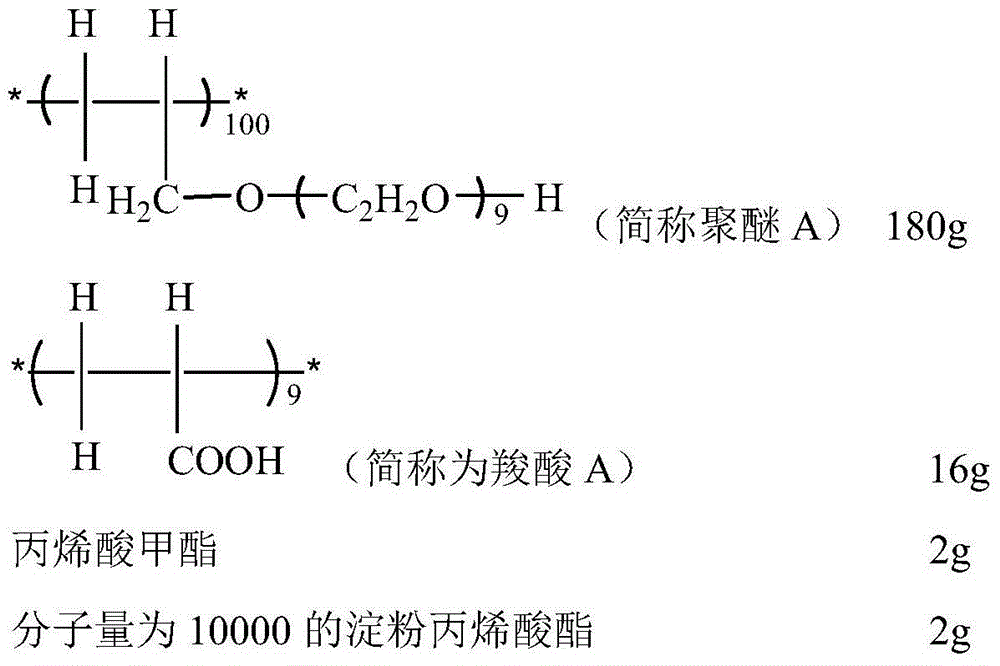

Special concrete pumping agent for ultra-high buildings and preparation method thereof

The invention relates to a special concrete pumping agent for ultra-high buildings. The special concrete pumping agent is prepared from raw materials of polyether monomers containing double bonds, unsaturated carboxylic acid and derivative monomers thereof, unsaturated carboxylic acid ester and derivative monomers thereof, a bleeding-improved assistant, a chain transfer agent and an initiator, wherein water reducing agents are composed of polyether monomers containing double bonds, unsaturated carboxylic acid and derivative monomers thereof, unsaturated carboxylic acid ester and derivative monomers thereof and bleeding improved assistants; the adding amount of the initiators and the adding amount of the chain transfer agents are 0.2-0.5% and 0.05-0.2% of the total weight of water reducing agents respectively. The special concrete pumping agent does not need to be compounded with other additives, is simple in ingredients, has effects of water reducing and slump conserving on concrete, reduces initial viscosity of concrete, avoids the bleeding phenomenon in ultra-high concrete pumping, and is suitable for smooth pumping of concrete to ultra-high buildings over 100 meters.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

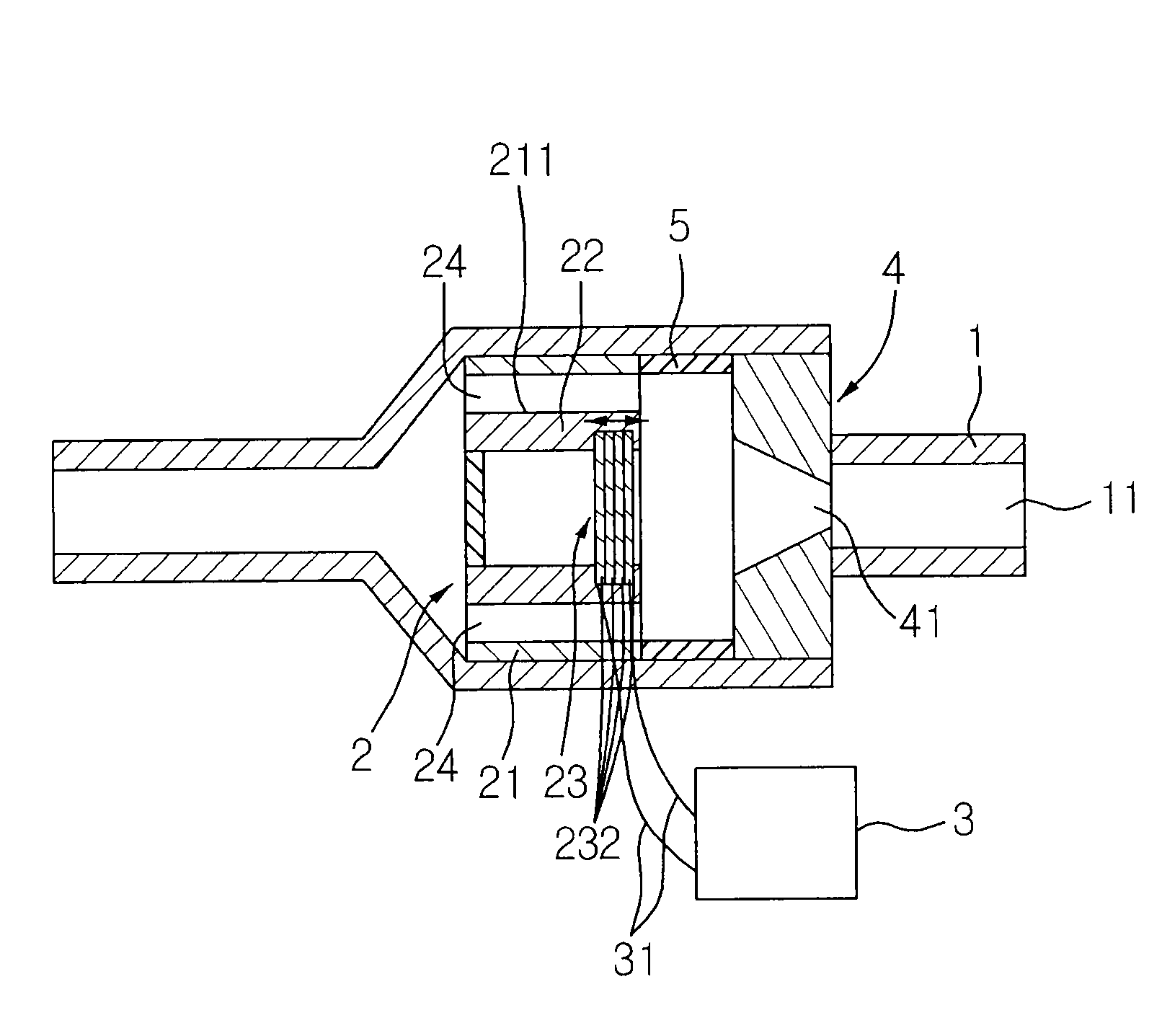

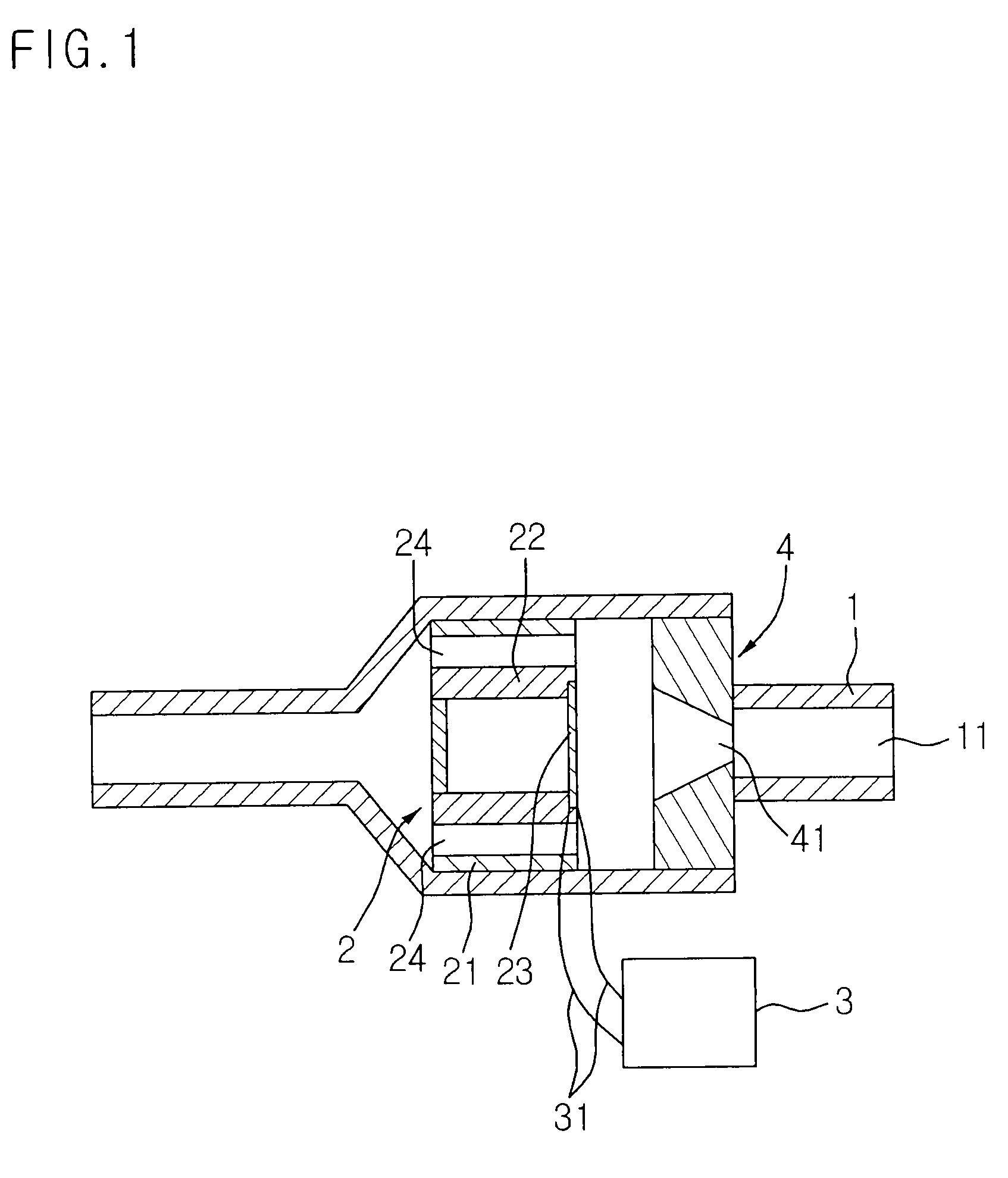

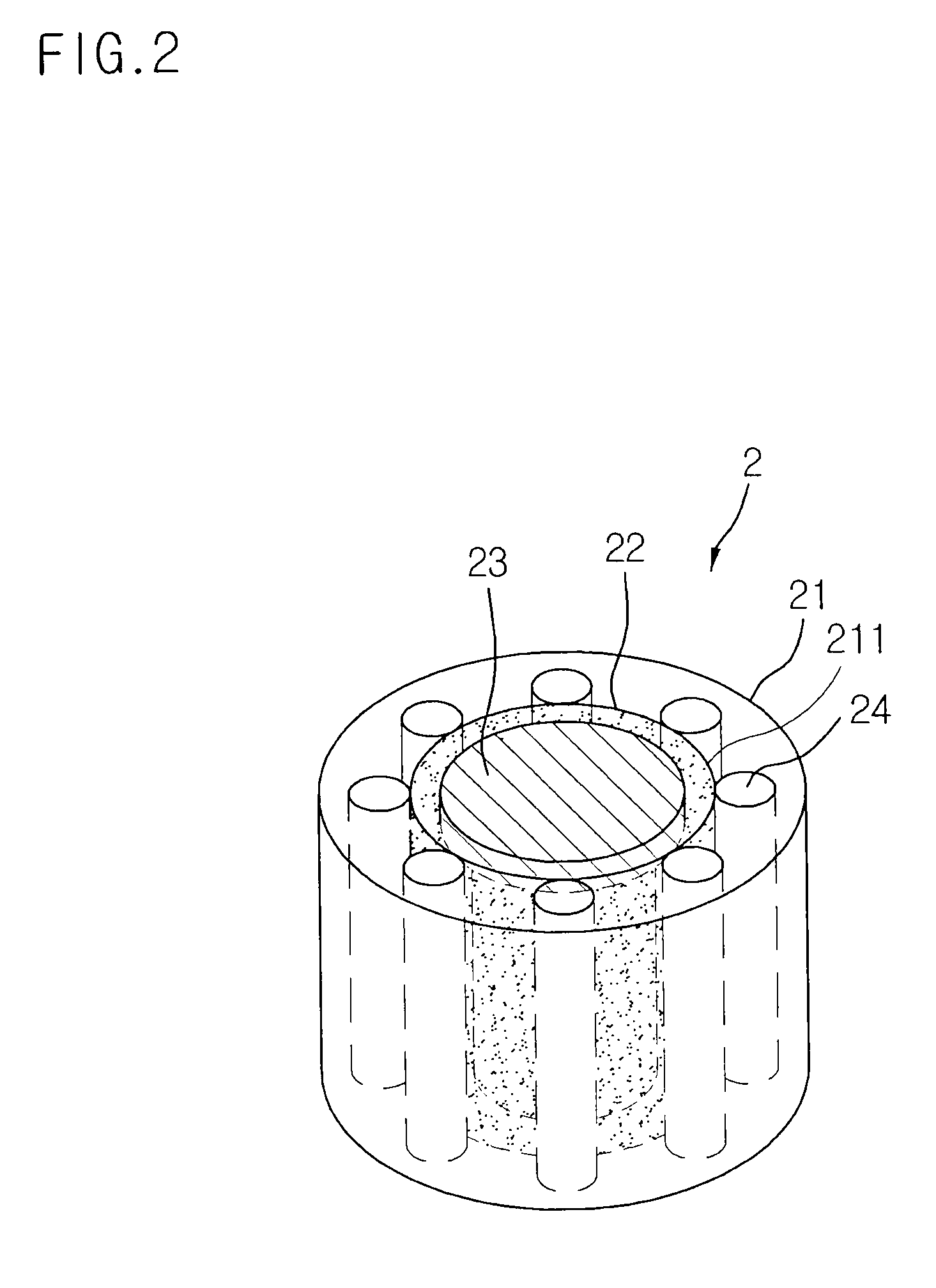

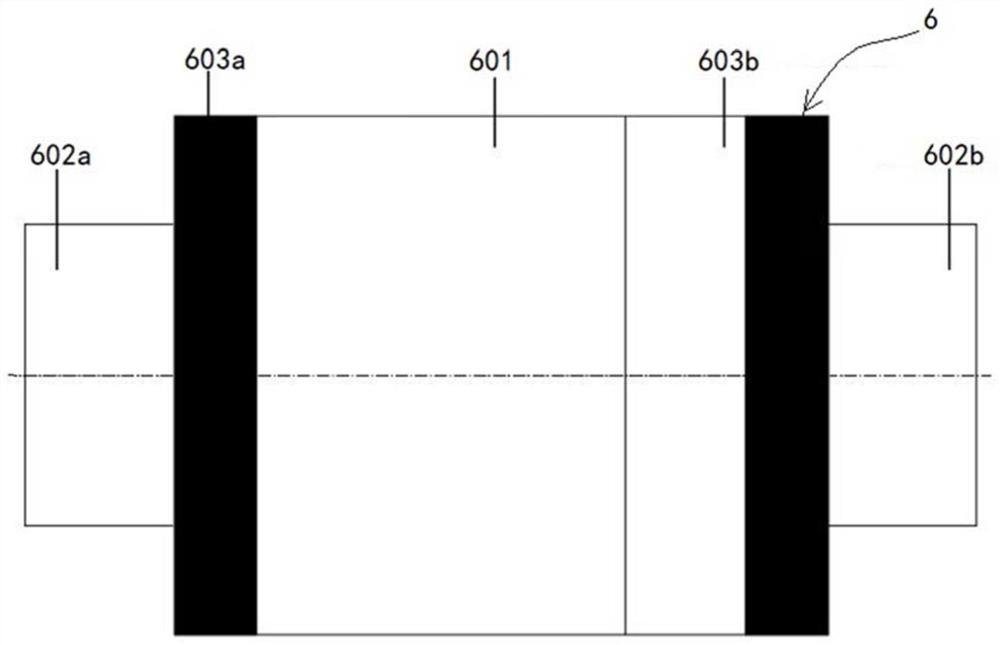

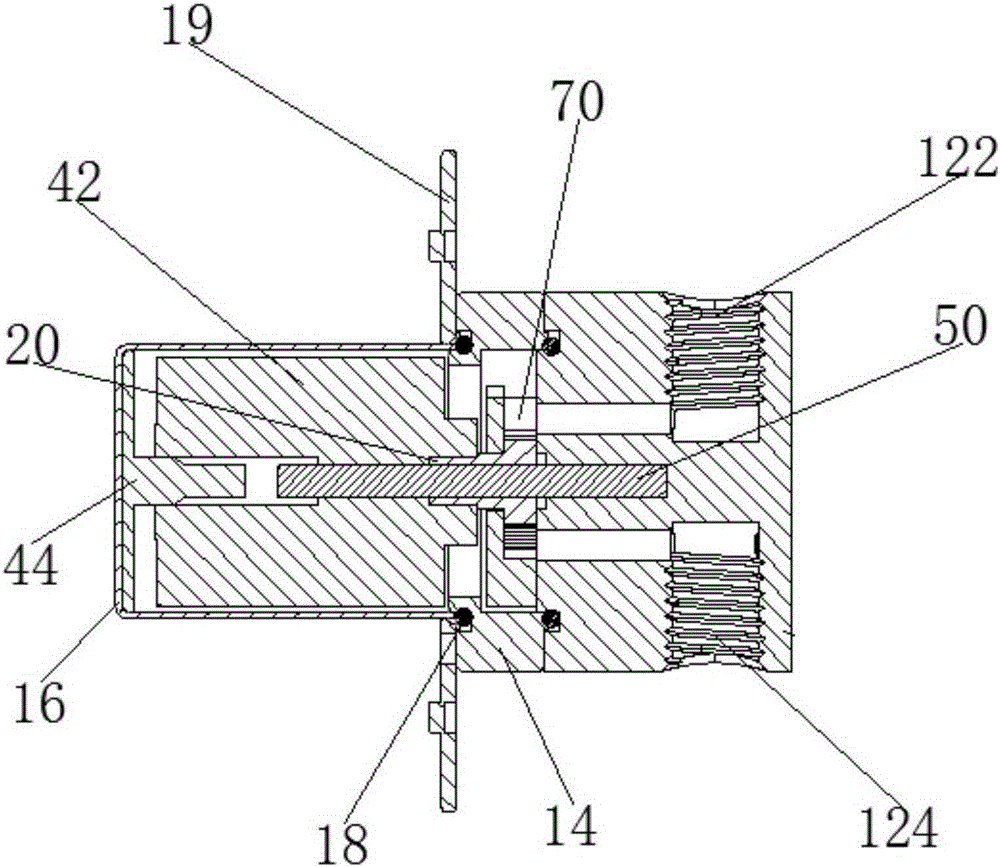

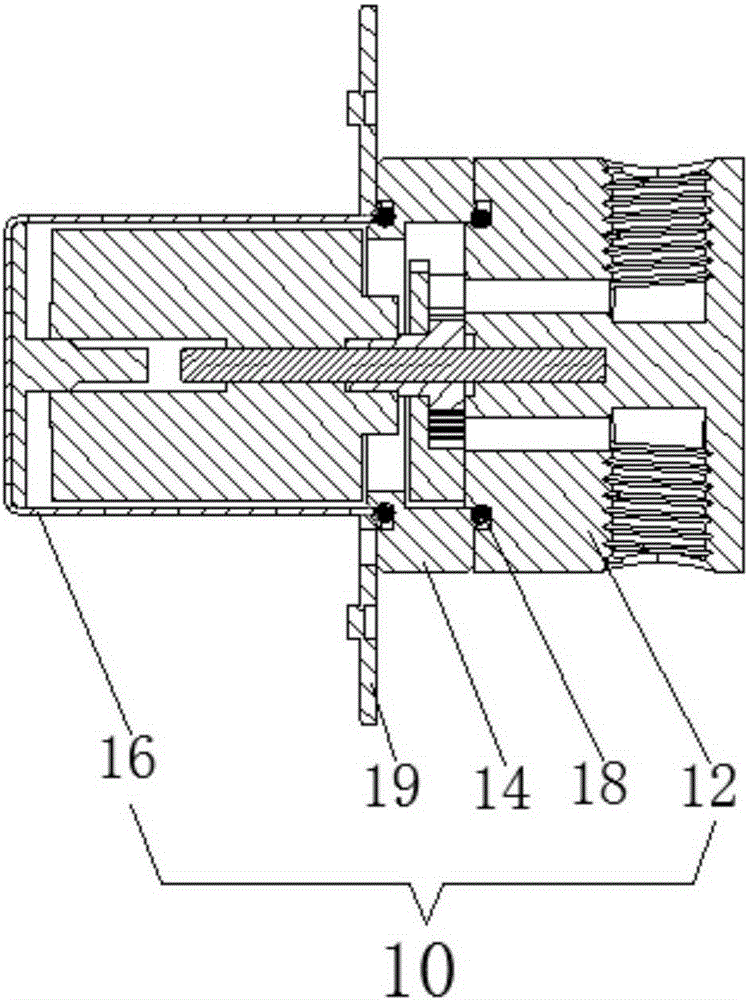

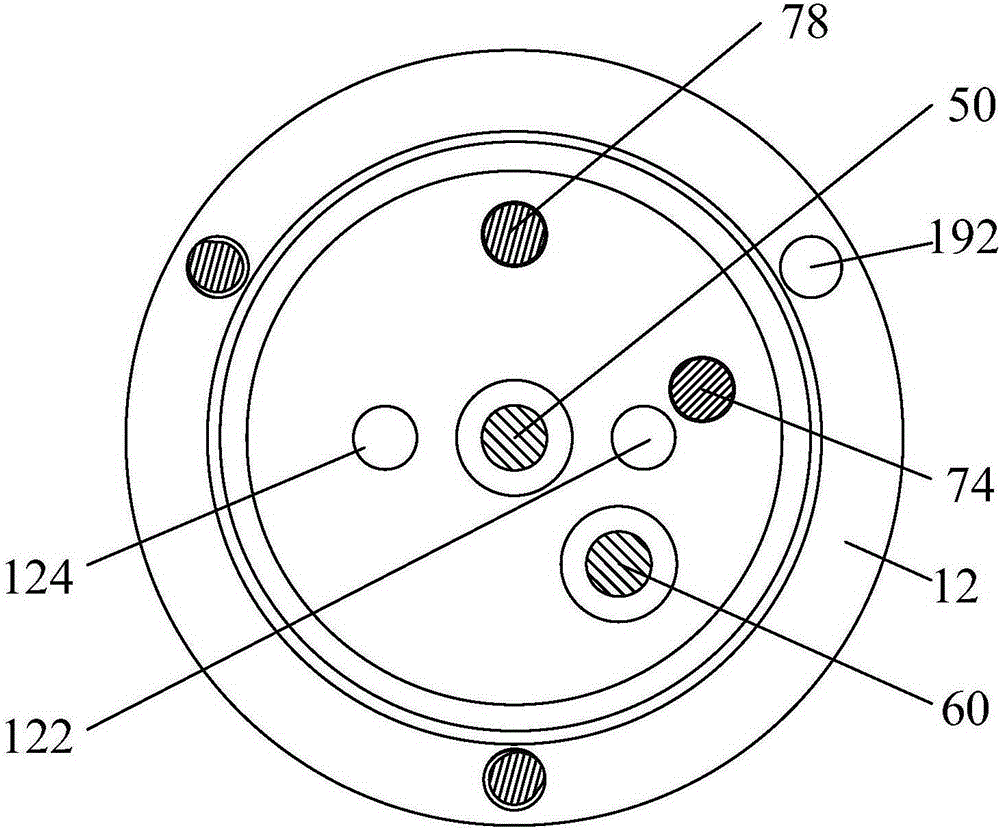

Ultrasonic piezoelectric pump

InactiveUS20090232681A1Easy dischargeSmooth pumpingPositive displacement pump componentsPiston pumpsElectricityPiezoelectric actuators

Disclosed is an ultrasonic piezoelectric pump in which a piezoelectric pump is integrated with a fluid pipe without a check valve so that the structure can be simplified. The pump includes a fluid pipe having a hollow part formed therein to permit a fluid to flow from a fluid source, a piezoelectric actuator inserted into the hollow part and including a piezoelectric device and a plurality of fluid holes, a controller connected to a lead wire to apply a driving power to the piezoelectric device, and a tapered nozzle inserted into the hollow part in front of the piezoelectric actuator and tapered forward and downwardly.

Owner:KOREA INST OF MACHINERY & MATERIALS

Concrete pump moisturizing agent and using method thereof

ActiveCN108329985AReduce frictional resistancePerformance is not affectedLubricant compositionSolubilitySodium sulfate

The invention discloses a concrete pump moisturizing agent and a using method thereof. The concrete pump moisturizing agent is prepared from the following raw materials in percentages by weight: 25-50% of polyacrylamide and 50-75% of sodium sulfate. Components of raw materials of the pump moisturizing agent are easily obtained, a production process is simple and convenient, the production cost islow, water solubility is good, construction is facilitated, adaptability to concrete and mortar is good, adverse effects on concrete do not exist, construction operability of concrete pumping can be greatly improved, and meanwhile, the concrete pump moisturizing agent is energy-saving and environmentally friendly, and has good industrial prospect.

Owner:WUHAN YUANJING READY MIXED CONCRETE CO LTD

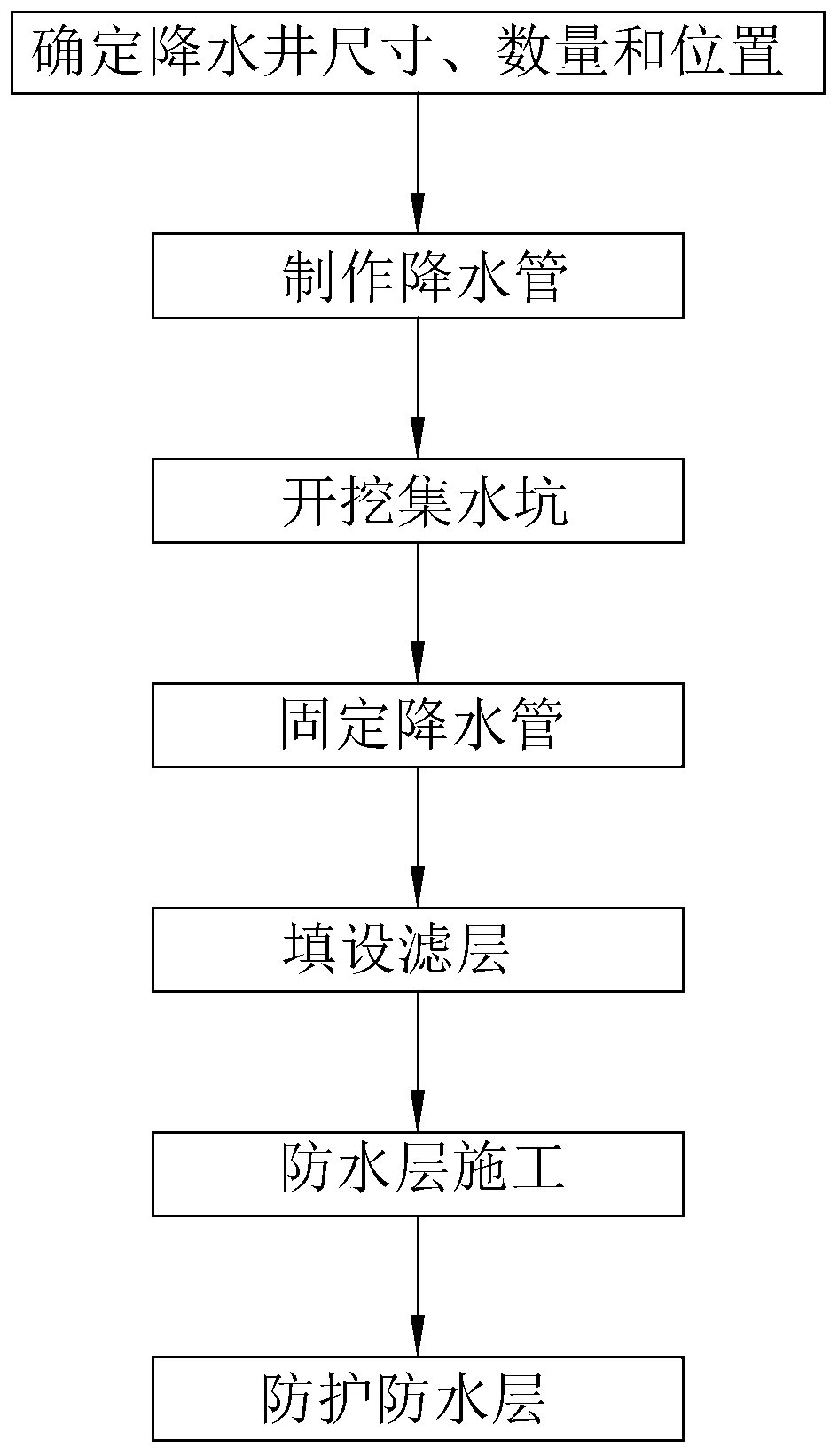

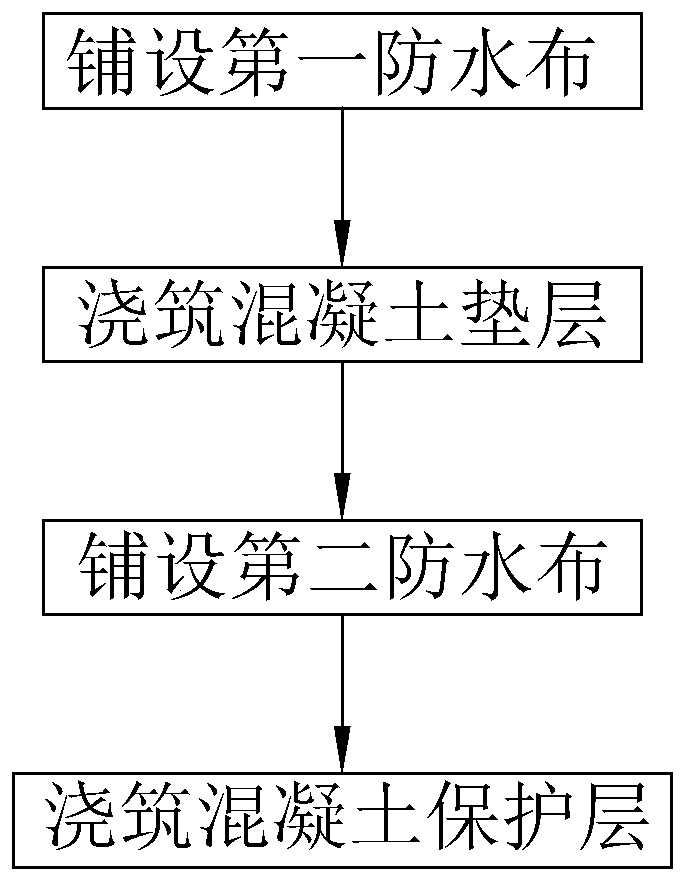

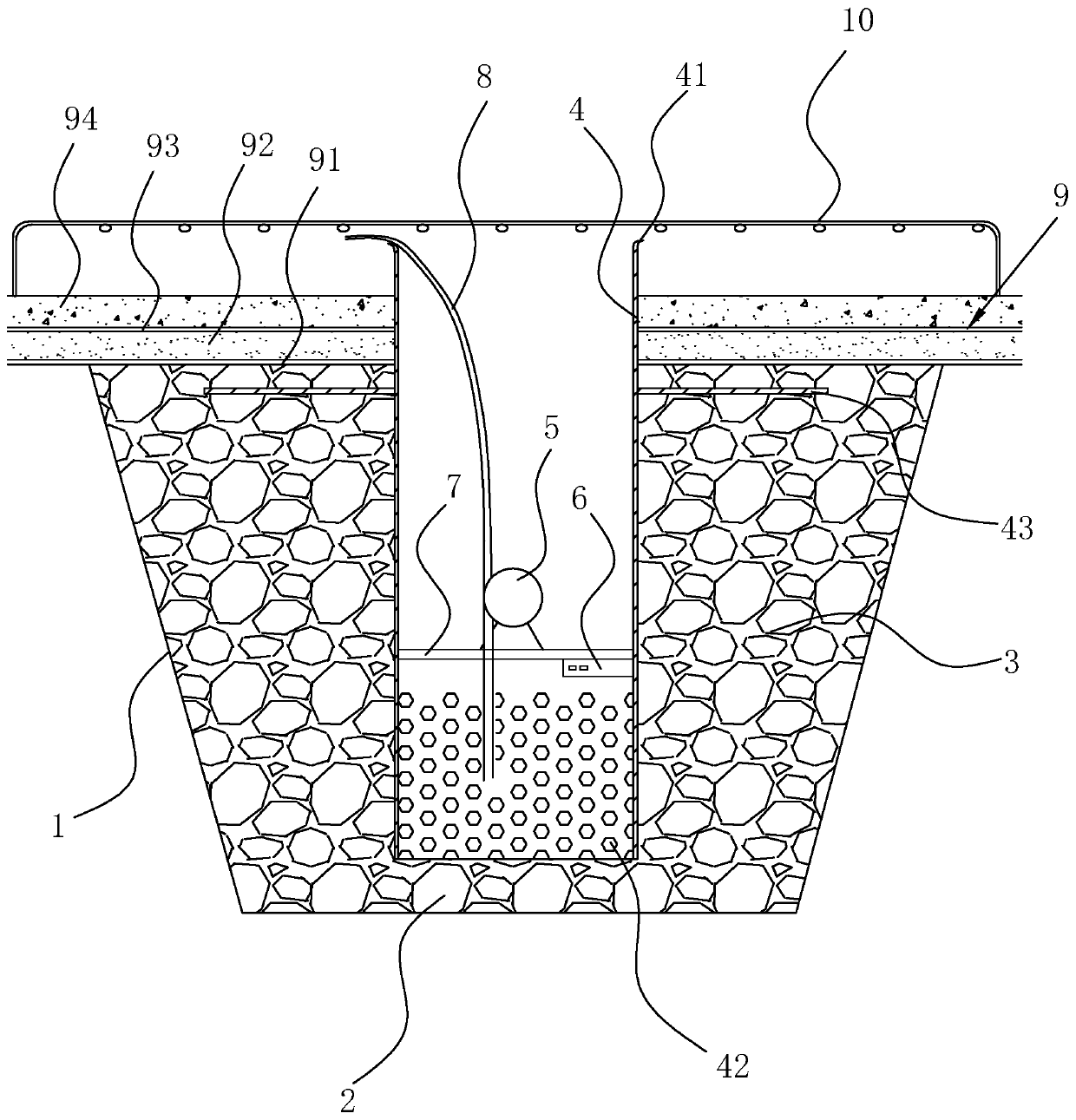

Foundation pit local dewatering construction method

InactiveCN110820778APrevent hole collapseAvoid cloggingExcavationsWater dischargeArchitectural engineering

The invention relates to a foundation pit local dewatering construction method, relates to the technical field of foundation pit dewatering, and aims at solving the problems that an existing dewatering well easily receives impact of underground water, and easily generates the hole collapse condition, or even well wall slurry collapsing can occur, and a water discharging pump is blocked. The methodcomprises the following steps of Step 1, determining the dimension, quantity and positions of dewatering wells; Step 2, manufacturing dewatering pipes; Step 3, digging water collecting pits; Step 4,fixing the dewatering pipes; Step 5, filling and installing filtering layers; and Step 6, constructing waterproof layers. The foundation pit local dewatering construction method has the beneficial effect that a hole collapsing phenomenon of the dewatering wells can be reduced.

Owner:陕西神州实业有限公司

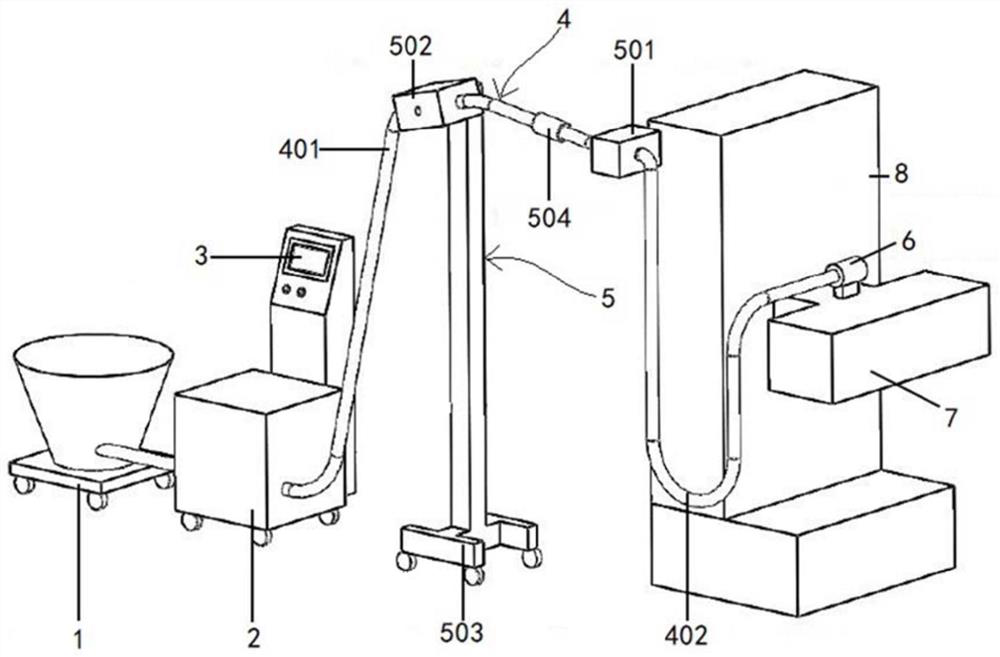

Automatic feeding system

InactiveCN112356283AImprove feeding efficiencyLabor savingDischarging apparatusBuilding constructionsControl engineeringProcess engineering

The invention provides an automatic feeding system. The automatic feeding system comprises a storage device used for supplying building materials with fluidity, a pumping device, a feeding pipeline and a pumping control device, wherein the pumping device is connected with the storage device, provides power for conveying the flowing building materials, and can pump the flowing building materials from the interior of the storage device; the feeding pipeline is connected with a discharging opening of the pumping device, and the flowing building materials are conveyed to an external executing mechanism through the feeding pipeline; and the pumping control device controls starting and stopping of feeding of the pumping device, measures the flow of the feeding pipeline or the feeding pressure and weight of the executing mechanism, judges whether current feeding meets the feeding requirement or not according to a measurement result and the working efficiency of the executing mechanism, adjusts the pumping efficiency of the pumping device according to the judgment result, and achieves accurate control over feeding. According to the automatic feeding system, the feeding efficiency can be greatly improved, and labor force consumed by manual feeding is avoided; and meanwhile, feeding is accurately controlled, material waste is reduced, and the construction cost is reduced.

Owner:上海蔚建科技有限公司

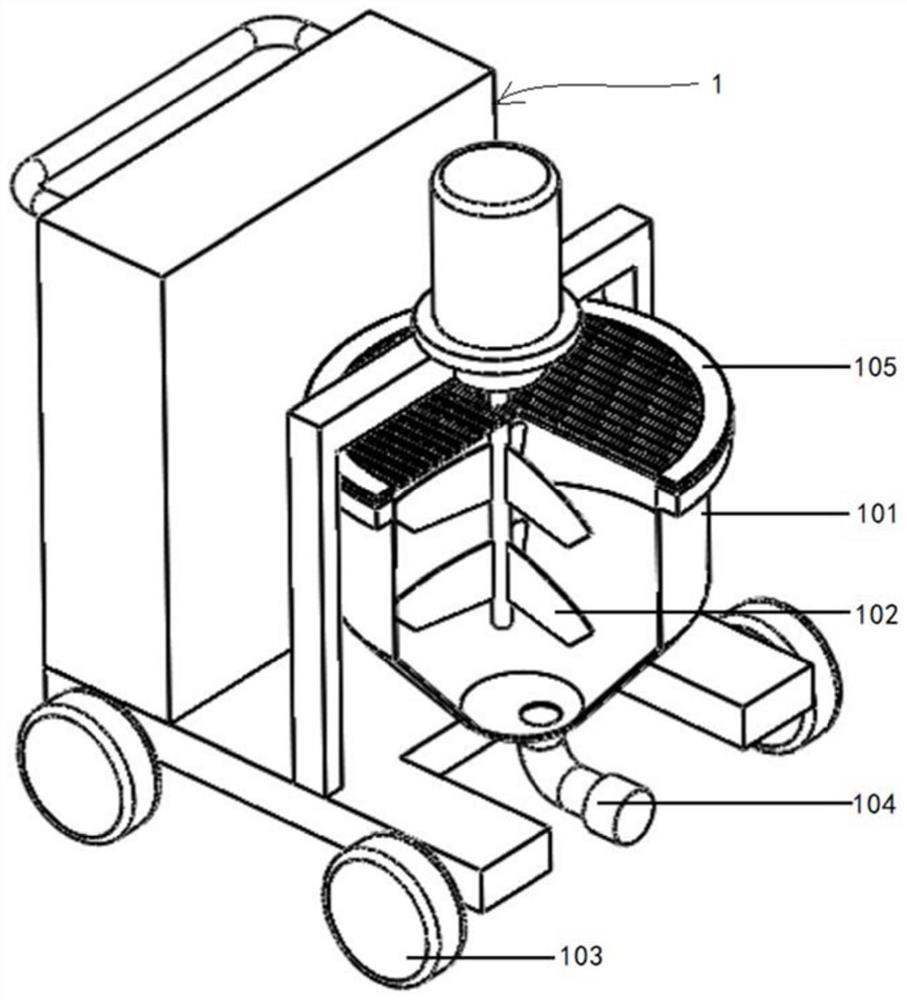

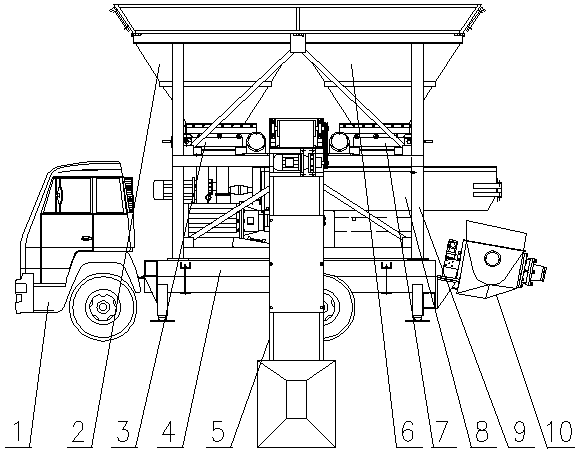

Self-propelled proportioning, stirring and pumping vehicle

InactiveCN103341912AConvenient for field workImprove liquidityCement mixing apparatusSmall footprintConcrete pump

The invention discloses a self-propelled proportioning, stirring and pumping vehicle belonging to the technical field of building machinery equipment. A rack of the whole vehicle is arranged on a chassis of a truck; a cobble bin, a sand bin, a cement feeding device and a concrete pumping device are arranged on the rack of the whole vehicle; a sand screening device is arranged at the upper part of the sand bin; the cement feeding device is formed in a way that a cement hopper is connected with a material inlet of a stirrer by a conveying belt; the cobble bin, the sand bin and the cement hopper are provided with flow control gates; the stirrer is positioned below the cobble bin and the sand bin in the rack of the whole vehicle and is downwards communicated with a stirring hopper of the concrete pumping device; a pumping main body is fixed on the chassis of the truck by U-shaped clips. The vehicle has the beneficial effects that concrete stirring and pumping devices are arranged on the vehicle together so as to be transported to a construction site fast for operation, so that the field operation and flow construction can be facilitated, simultaneously the automation and the lighting of one-site concrete stirring are realized, the stirring quality is good, the proportioning metering is accurate, the pumping is smooth, the occupied land is small, the production efficiency is high, the use is safe, the maintenance is convenient, and devices can be dismounted randomly and can be used singly, so that the vehicle is relatively flexible.

Owner:安阳市圆通机械有限公司

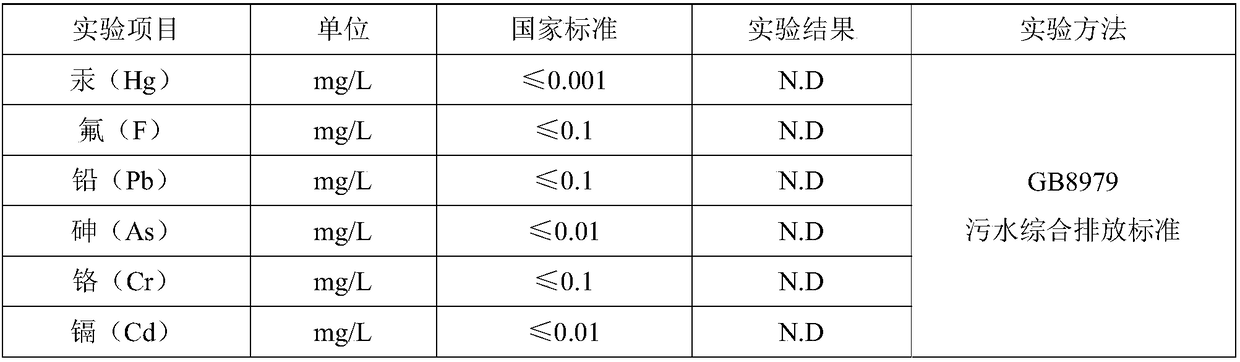

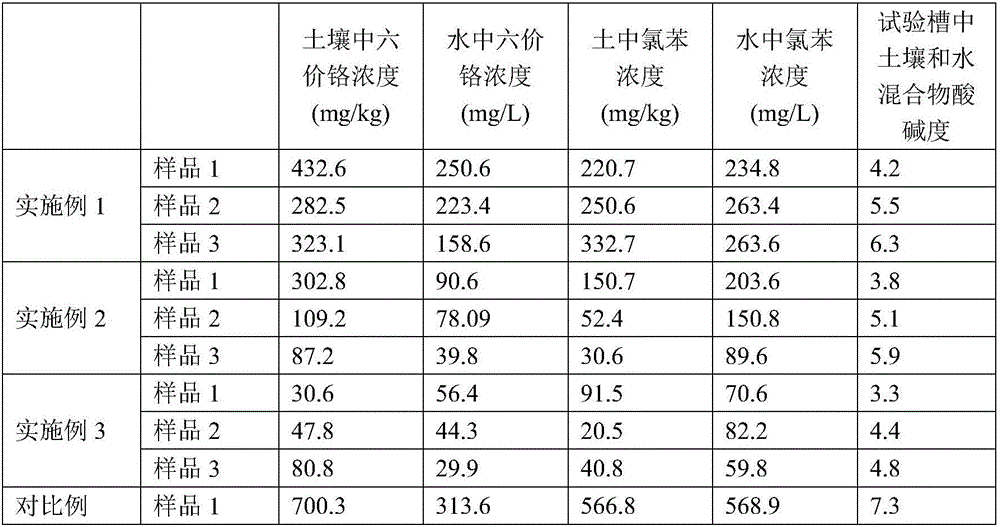

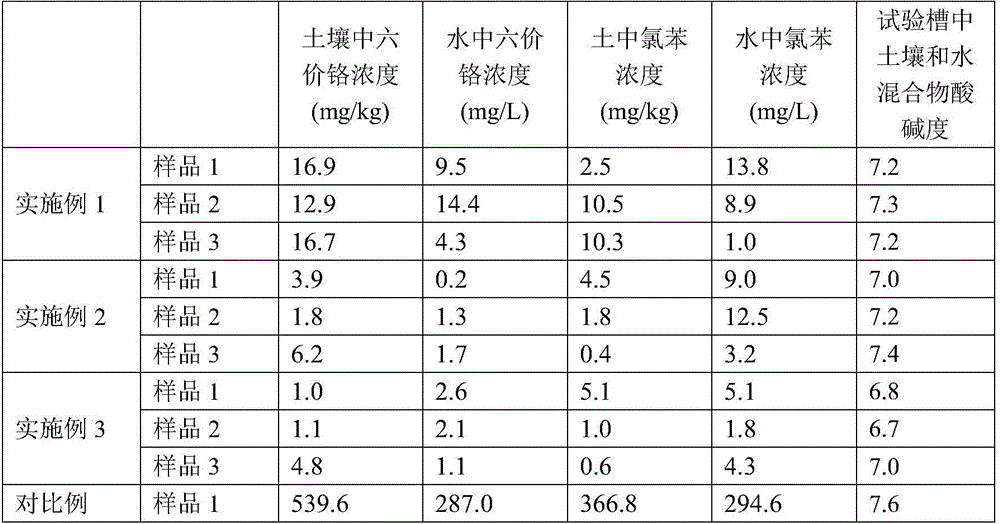

Novel reducing agent for repairing contaminated site and preparation method of novel reducing agent

ActiveCN106825027AHigh recovery and repair efficiencyAvoid passivationWater contaminantsContaminated soil reclamationHydrogenIron powder

The invention discloses a novel reducing agent for repairing a contaminated site. The novel reducing agent is prepared from the following components in percentage by mass: 70 percent to 95 percent of micron iron powder and 5 percent to 30 percent of an auxiliary agent, wherein the auxiliary agent is prepared from the following components in percentage by mass: 45 percent of xanthan gum, 54 percent of waste molasses and 1 percent of acetic acid bacteria powder. The reducing agent can also be used for effectively avoiding deposition and agglomeration phenomena in a utilization process of the micron iron powder, and uniform dispersion degrees of the micron iron powder in a polluted soil body and a polluted water body are remarkably improved; an oxidation-reduction potential of a reaction system is greatly reduced, and the reduction removal rate of the micron iron powder on pollutants in the soil and underground water is remarkably improved; the potential of hydrogen of a balance reaction system can be effectively balanced; finally, efficient reduction and recovery of the pollutants in the soil and underground water is realized. Meanwhile, the invention further provides a preparation method of the reducing agent; the utilization rate of waste materials can be realized, the preparation cost is low and the operation is simple and easy.

Owner:SOUTHEAST UNIV

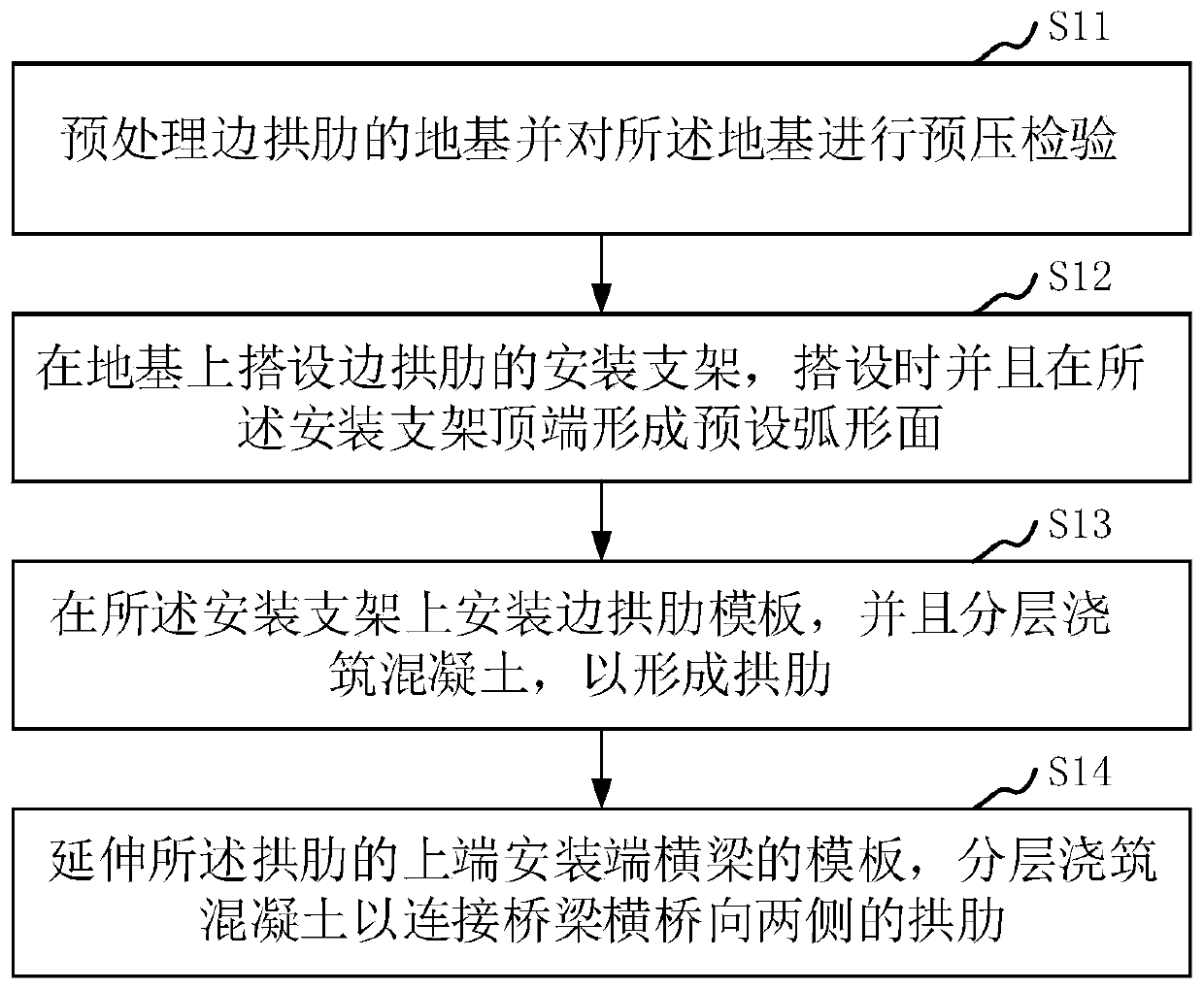

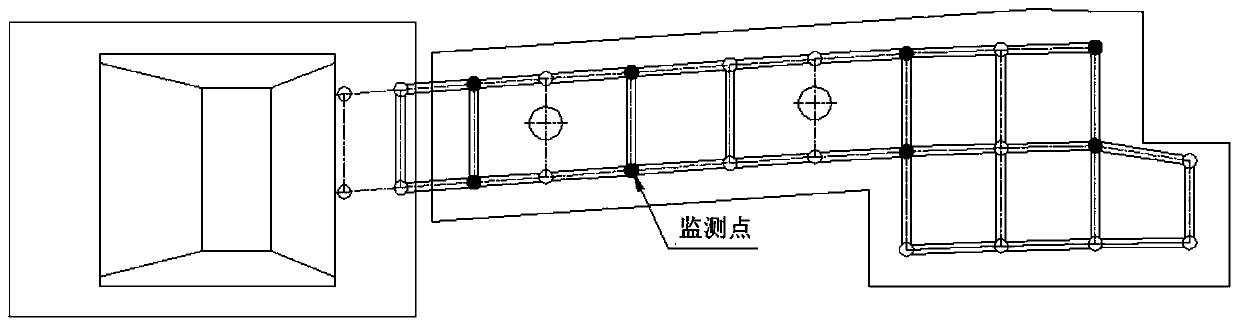

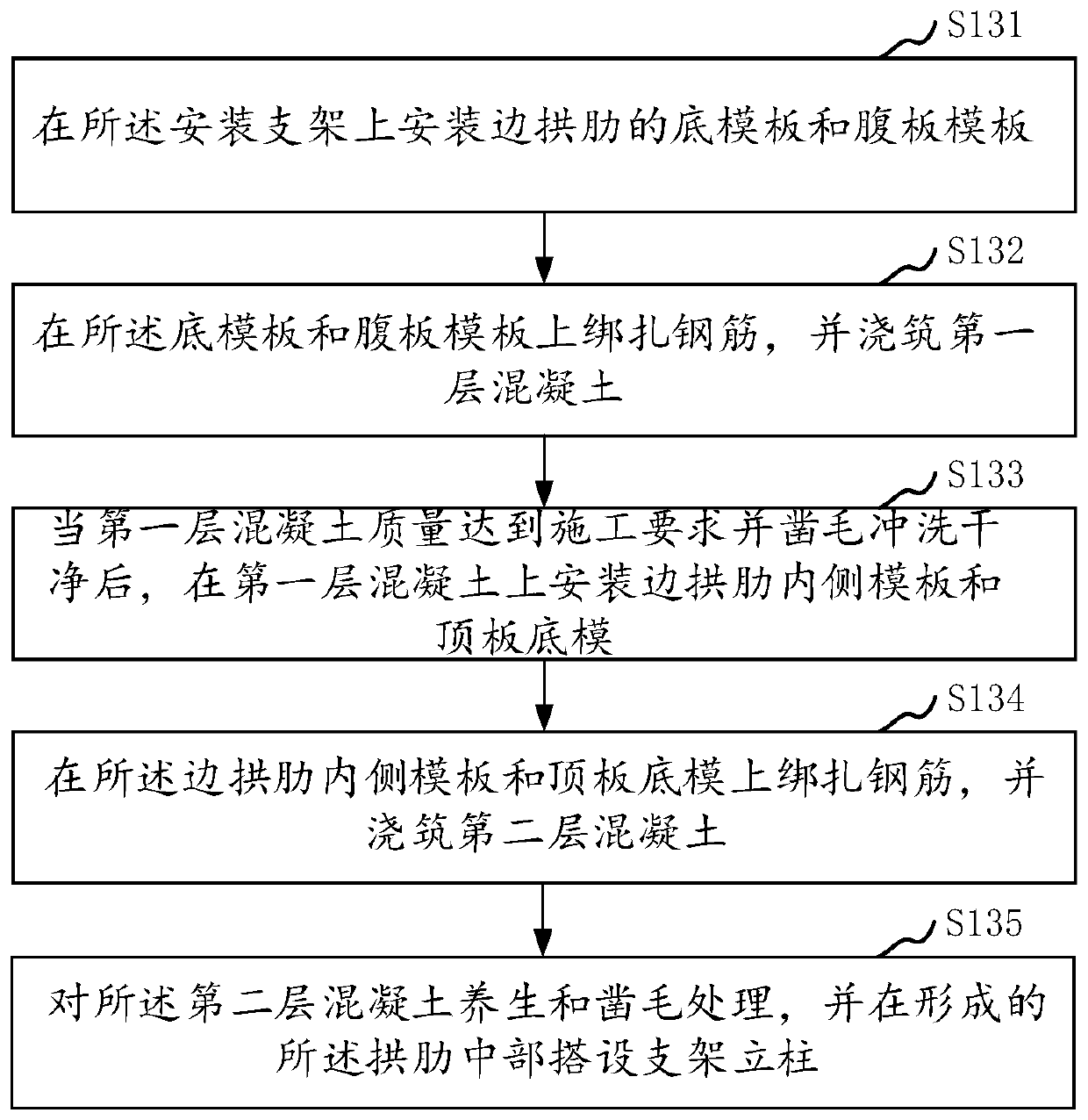

Side arch rib construction method and side arch rib

InactiveCN110777635AImprove stabilityImprove bearing capacityBridge erection/assemblyIn situ soil foundationArchitectural engineeringStructural engineering

Owner:ROAD & BRIDGE SOUTH CHINA EINGINEERING CO LTD +1

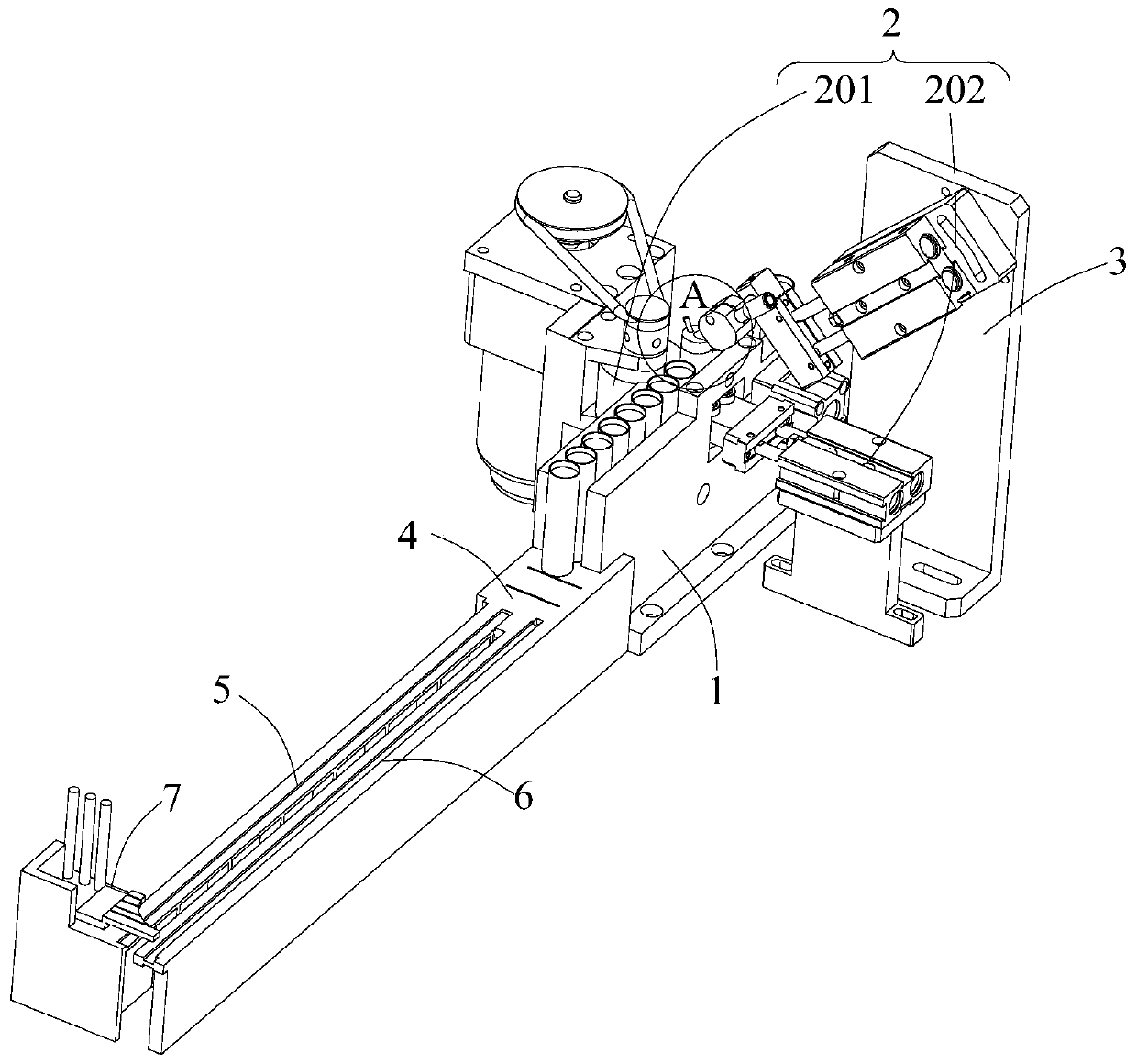

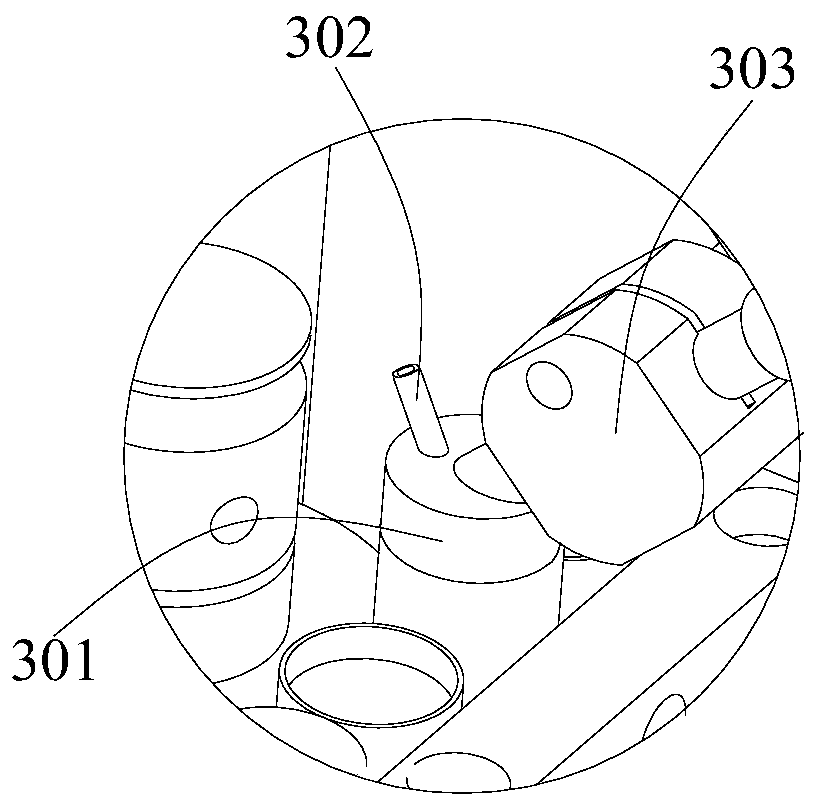

Cement filling mechanism for engineering machinery

PendingCN109733652AAchieve placementAchieve weighing effectSolid materialPackaging automatic controlEngineeringBody positions

The invention relates to a cement filling mechanism for engineering machinery. The cement filling mechanism comprises feeding guide tracks, a feeding assembly, a filling assembly, a weighing track, anadvancing track, a removing track and a removing mechanism, wherein tank bodies are placed between the feeding guide tracks, the side parts of the feeding guide tracks are provided with opening portscorrespondingly; the feeding assembly comprises an active feeding roller and a driven feeding part, wherein the driving feeding roller is arranged in one opening port, and the driven feeding part isarranged in another opening port; the position of the filling head of the filling assembly and the filling head are coaxially provided with a dustproof funnel, the dustproof funnel is suitable for being arranged at the inlet of each tank body in a covering mode, and an ash suction pipe communicating with the inner cavity of the dustproof funnel is arranged at the end part of the dustproof funnel;the weighing track is located at the outlet ends of the feeding guide tracks, and the weighing track is suitable for being connected with the tank bodies positioned on the feeding guide tracks; and the advancing track is located at an outlet of the weighing track, the advancing track is suitable for being connected with the tank bodies positioned on the weighing track, the removing track is located on one side of the advancing track, and the removing mechanism is suitable for removing the tank bodies located on the advancing track to the removing track. According to the cement filling mechanism, rising dust can be conveniently reduced, and the tank bodies with relatively low quality can be removed conveniently.

Owner:崔洁

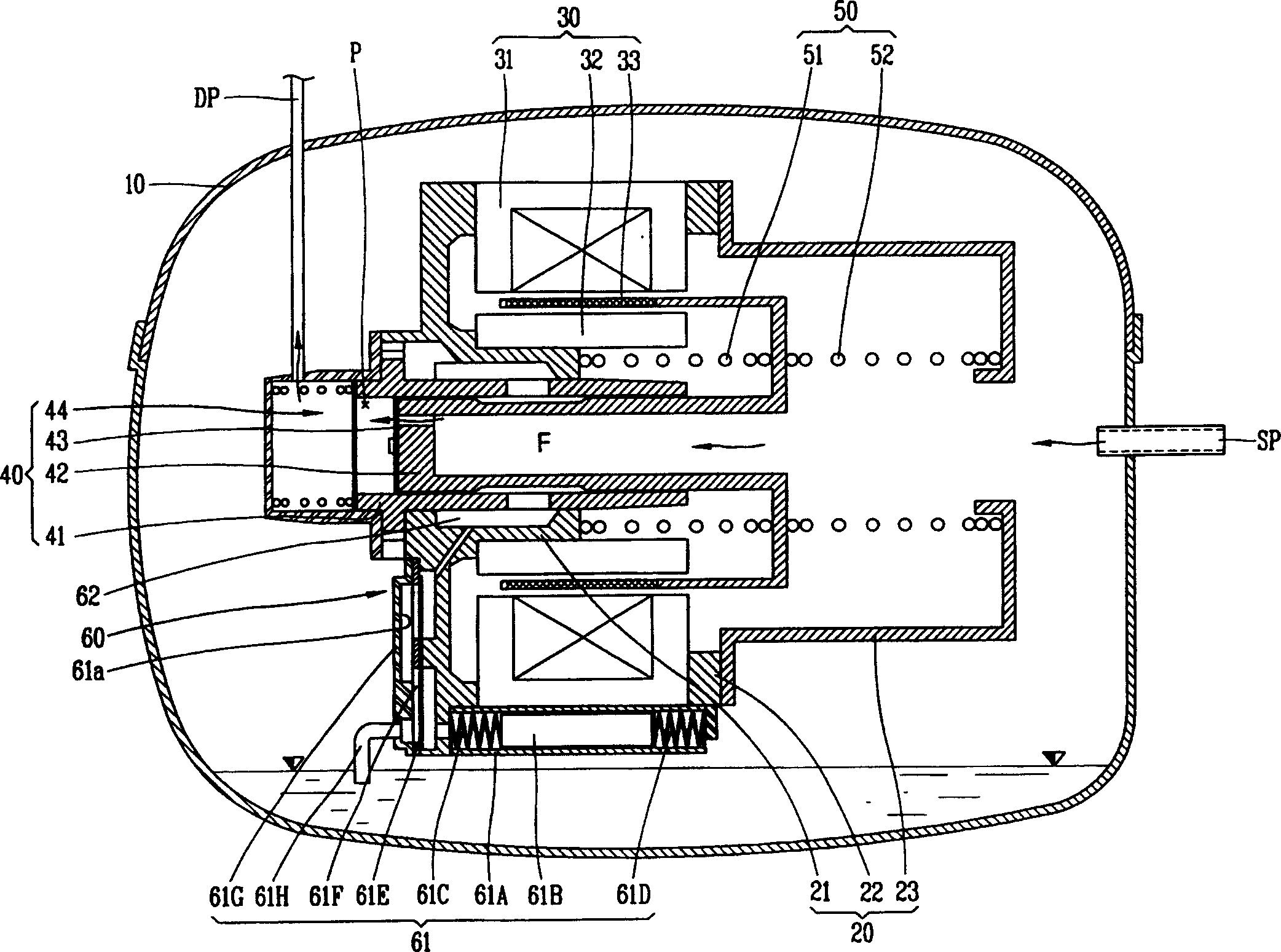

Oil feeder for lubricant in reciprocal movement type compressor

InactiveCN1626799ASmooth pumpingReduce frictionPositive displacement pump componentsPumpsForeign matterReciprocating motion

The invention relates to a lubricating oil supply device of reciprocal compressor. It is characterized by that on two side surfaces of the lub oil piston in said reciprocal compressor a spring fixing portion is respectively formed, the above-mentioned lubricating oil spring can be placed and fixed on the above-mentioned spring fixing portion, so that the above-mentioned lub oil spring always can be relained in the orignial position, and said structure can make the lub oil spring be repeatedly comperssed and extended on the fixed position always so as to can raise oil supply performance.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

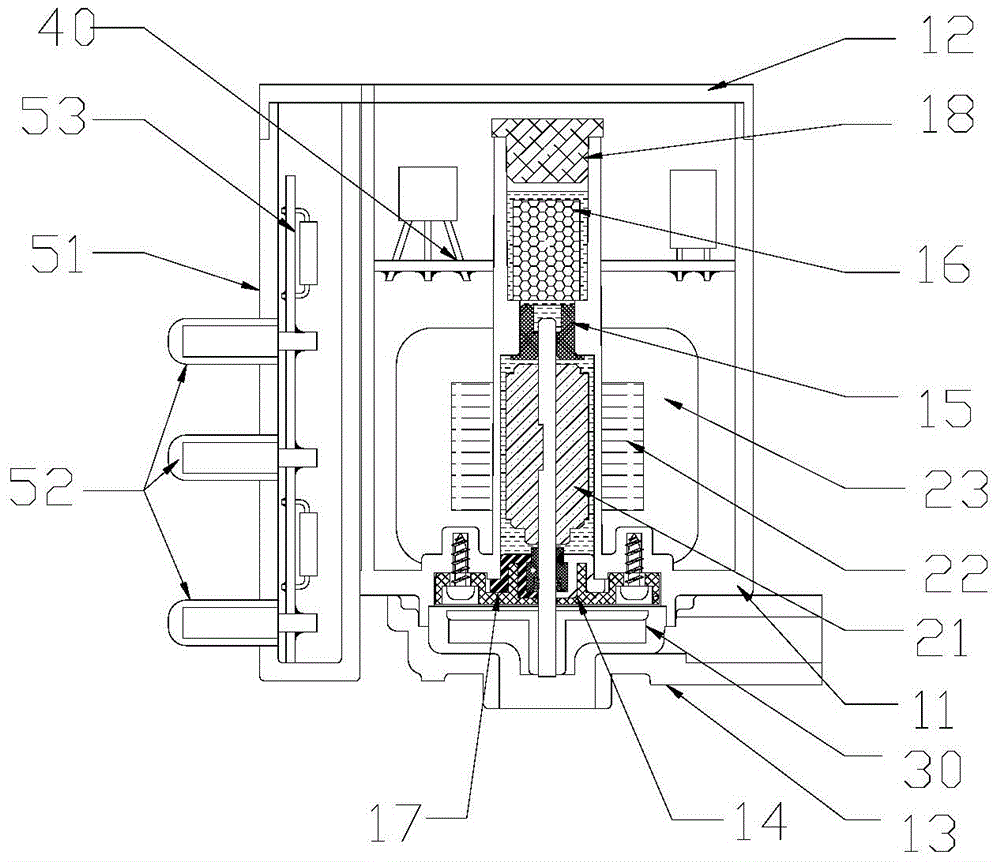

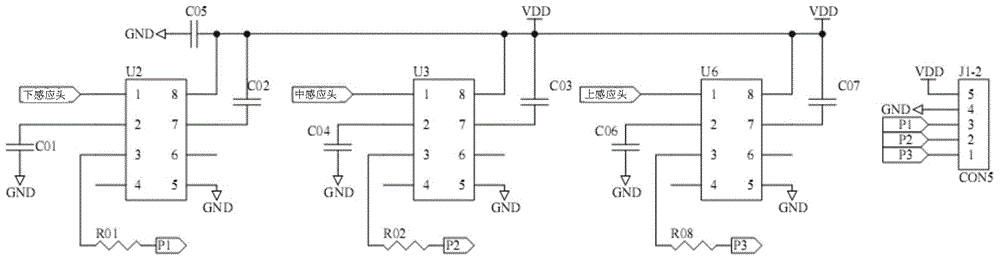

Automatic water level control water pump

ActiveCN104612980AReduce frequent starting problemsEasy to installPump controlPump installationsImpellerAutomatic control

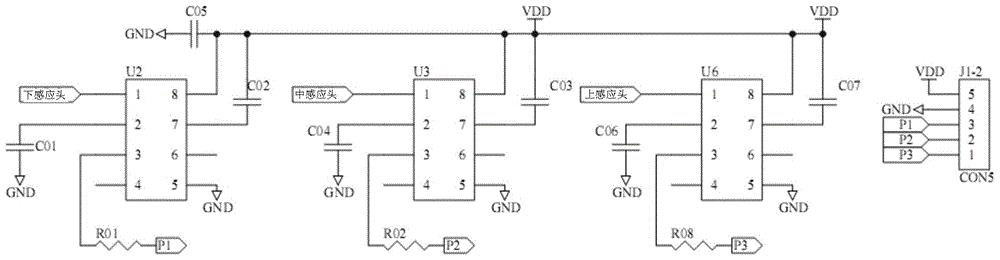

The invention provides an automatic water level control water pump. The automatic water level control water pump comprises a pump shell, an impeller, a water level detecting assembly, a control board and a motor. The motor and the impeller are arranged in a motor chamber and an impeller chamber of the pump shell respectively. The impeller is arranged on a rotating shaft of the motor, wherein the rotating shaft extends to the impeller chamber. The water level detecting assembly comprises a fixing shell, a detecting board and three water induction heads. The three water induction heads are located at different heights and connected to the detecting board. The fixing shell is fixed to the pump shell, the detecting board is installed in the fixing shell in a sealing mode, and at least one part of each water induction head is exposed out of the fixing shell. The control board is connected to the detecting board and drives the motor to run according to water induction head detecting signals from the detecting board. The motor is controlled to run according to the water level detected by the three water induction heads and the detecting signals, and the water level in an aquarium or an electric appliance device can be automatically controlled.

Owner:深圳市钜泰泵业有限公司

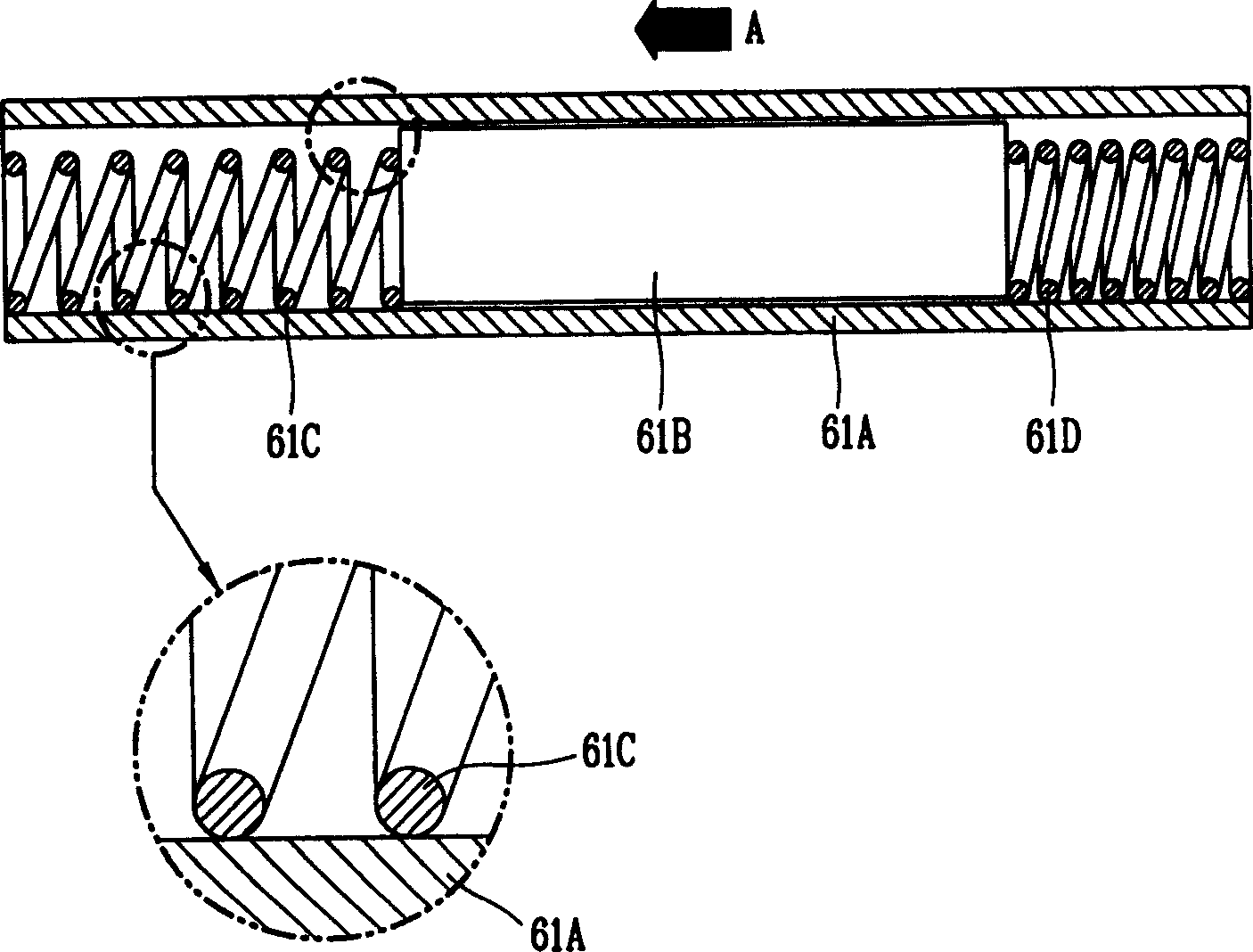

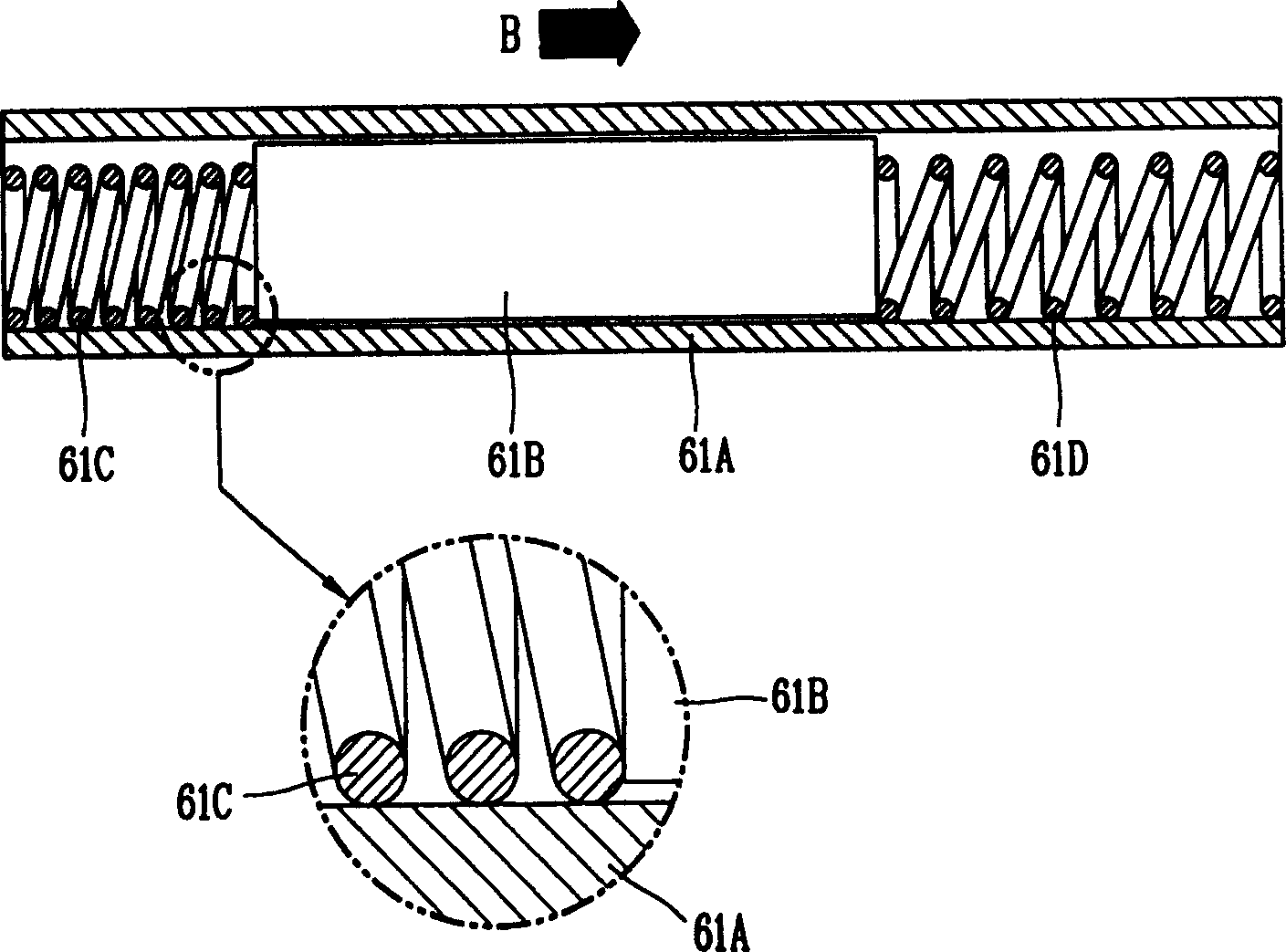

Coal mine slurry pump and crushing mechanism thereof

InactiveCN105736453AImprove operational efficiencySmall particlesPump componentsPumpsCoal waterFree rotation

The invention discloses a pulverizing mechanism of a coal mine slurry pump, which comprises multi-stage mixing knives arranged at the water inlet and freely rotatable, the mixing knives at each level are distributed along the axial direction of the water inlet, and The stirring knives all include a plurality of blades that are evenly distributed in the circumferential direction and are used to strike coal water impurities when rotating at high speed. The crushing mechanism disclosed in the present invention rotates at a high speed during operation, so that the coal water impurities are graded and crushed in the process of passing through the water inlet, and the size is rapidly reduced. When finally reaching the coal mine slurry pump, the particles of coal water impurities are enough Small and able to pump smoothly. Therefore, when the coal mine slurry pump discharges the coal water at the low-lying point of the coal mine site, the suspended impurities (such as coal gangue, etc.) can be classified and crushed to reduce the particle size of the entrained particles in the sewage and reduce the probability of pipeline blockage accidents. Improve pump operating efficiency. The present invention also discloses a coal mine slurry pump comprising the crushing mechanism, and its beneficial effect is as above.

Owner:兖矿能源集团股份有限公司

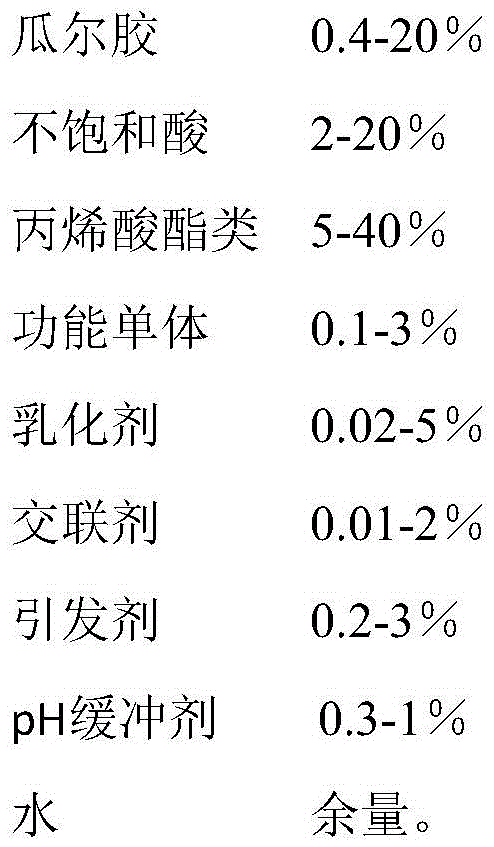

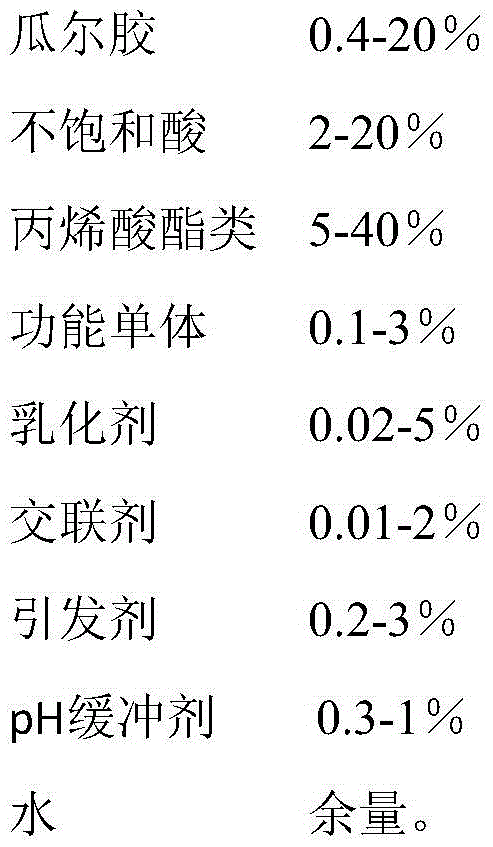

Modified guar gum thickener for papermaking paints and preparation method thereof

InactiveCN105601818AImprove liquiditySolve the problem of easy splashPaper coatingCoatingsFlocculationFunctional monomer

The invention belongs to the technical field of fine chemicals for papermaking, and particularly relates to a modified guar gum thickener for papermaking paints and a preparation method thereof. The thickener is prepared from the following raw materials in percentage by weight: 0.4-20% of guar gum, 2-20% of unsaturated acid, 5-40% of acrylate, 0.1-3% of functional monomer, 0.02-5% of emulsifier, 0.01-2% of crosslinking agent, 0.2-3% of initiator, 0.3-1% of pH buffering agent and the balance of water. The chemically modified guar gum has stabler structure, and overcomes the defect of high tendency to generate flocculation and microbes. The original dissolution by heating and stirring is changed into direct addition, thereby greatly lowering the heat energy, saving abundant time for preparing the papermaking paint, endowing the guar gum with favorable flowability, solving the problem of high splash tendency in the overcoating process of the papermaking paint, reducing the consumption of the adhesive, adhesion promoter and OBA (optical bleaching agent), and lowering the production cost.

Owner:QINGDAO XIANGZE CHEM CO LTD

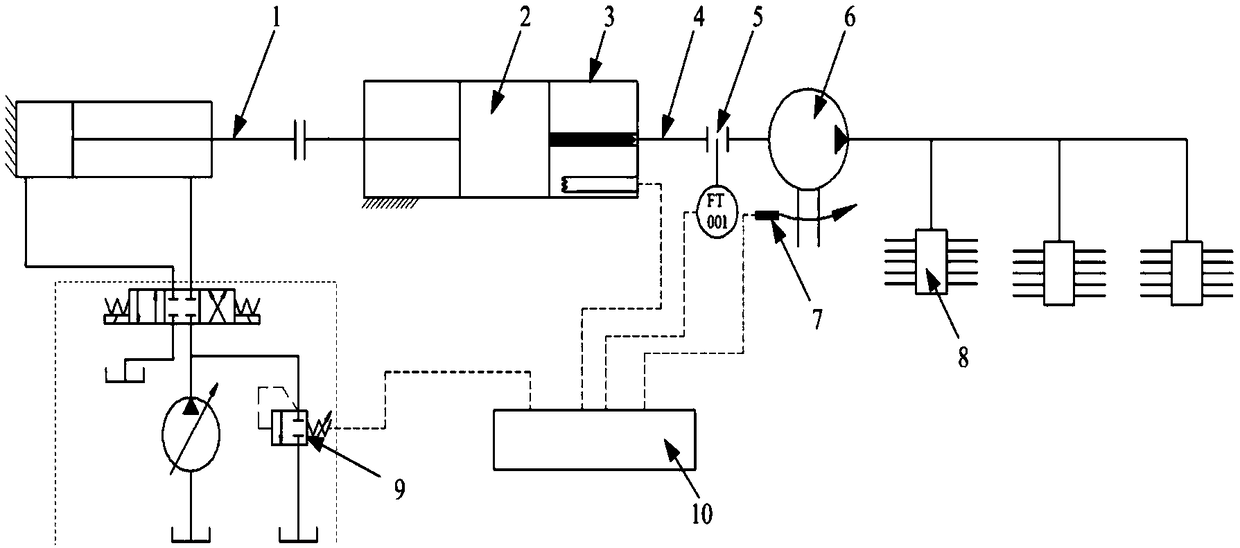

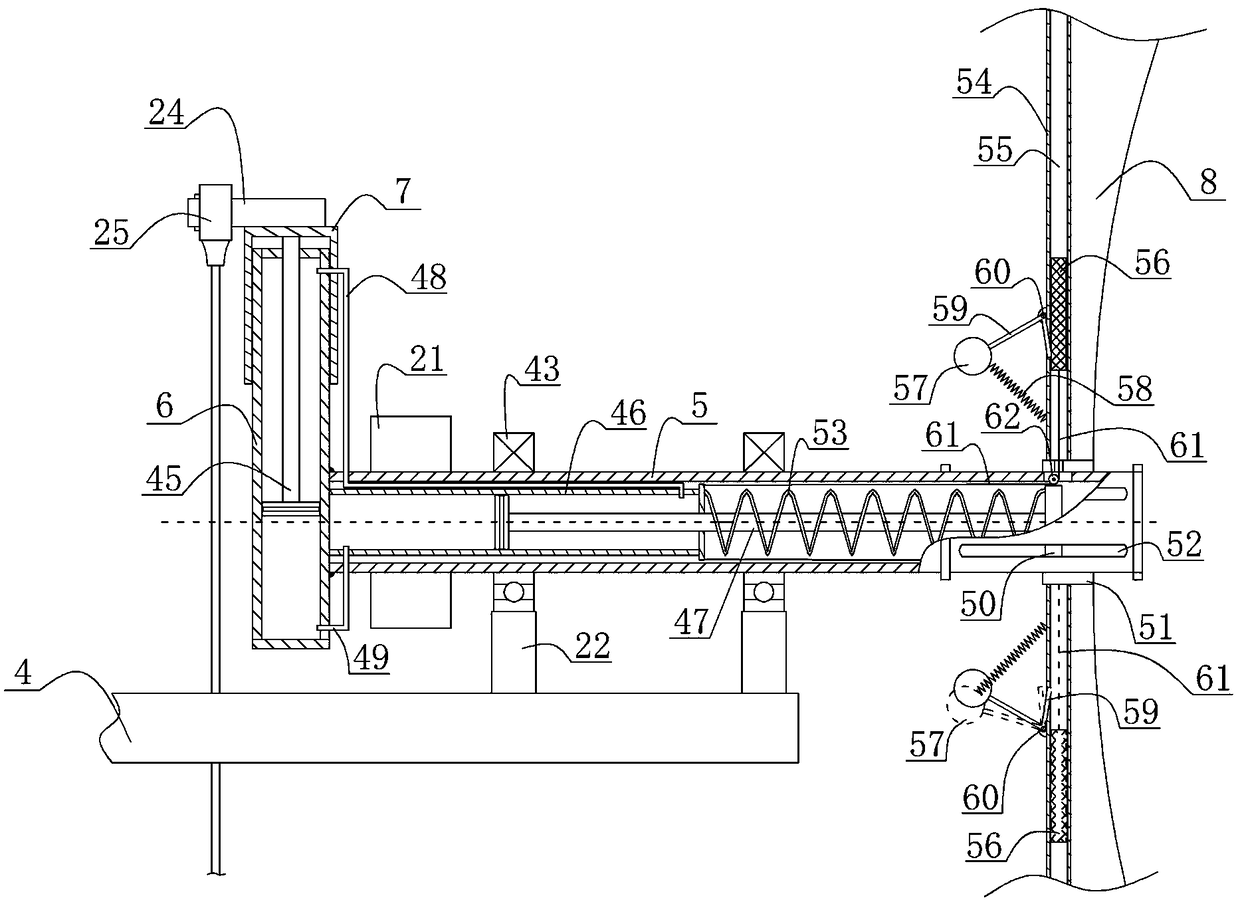

High-viscosity lubricating grease supplying and pumping system and method

ActiveCN109340546AIncrease viscosityStable pumpingLubricating pumpsLubrication elementsInlet pressureEngineering

The invention discloses a high-viscosity lubricating grease supplying and pumping system and method, and relates to the technical field of lubricating grease pumping systems. The high-viscosity lubricating grease supplying and pumping system comprises a grease storing cavity, grease supplying pipelines, a grease supplying pump, a pressurizing part, a heating part, a detecting part and a controller; the grease storing cavity is provided with one or more movable side walls, the input end of the grease supplying pump is connected to the grease storing cavity through the corresponding grease supplying pipeline, and an outlet of the grease supplying pump is externally connected to a distributor through the corresponding grease supplying pipeline; and the output end of the pressurizing part pushes the one or more movable side walls of the grease storing cavity in an abutting mode, and all or one section of the grease supplying pipeline between the grease storing cavity and the grease supplying pump is wrapped with the heating part. Lubricating grease can be heated and pressurized before entering the grease supplying pump, the viscosity of the high-viscosity lubricating grease is improvedthrough heating, the liquidity of the high-viscosity lubricating grease is improved, the effect of grease supplying pump evacuation caused by the insufficient inlet pressure in the pumping process ofthe lubricating grease is avoided through pressurizing, and finally the high-viscosity lubricating grease is pumped stably and reliably.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

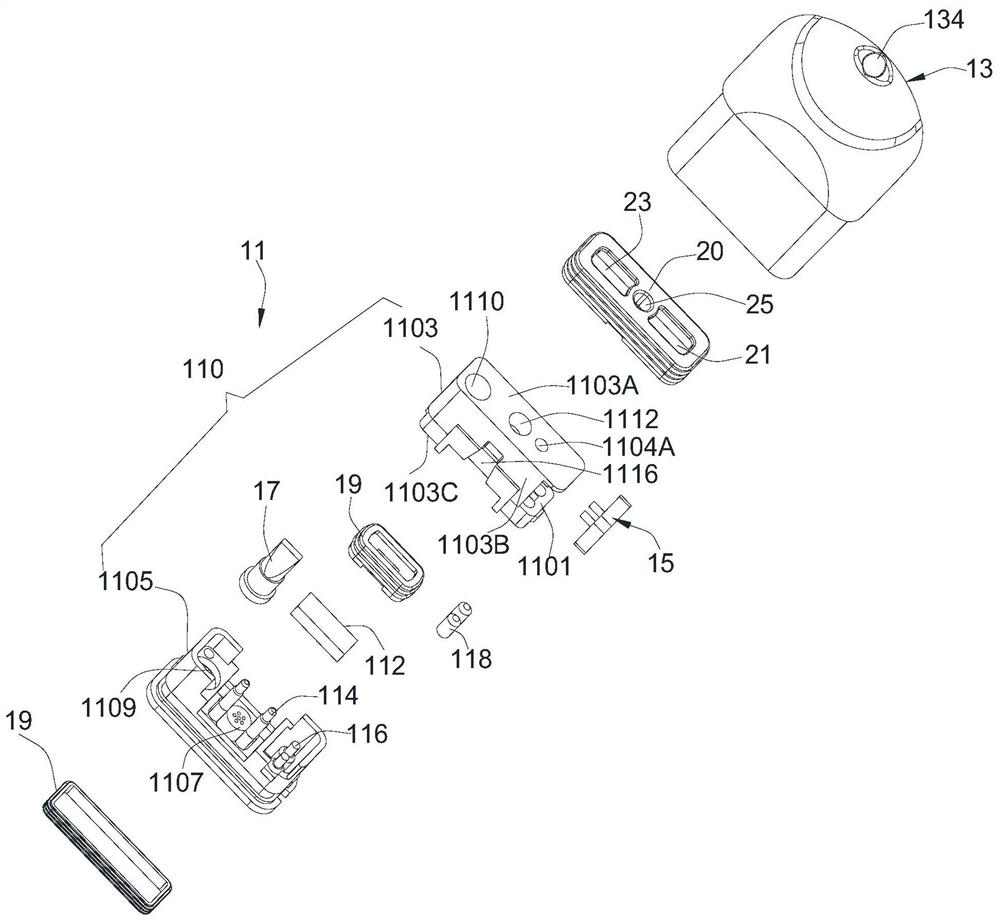

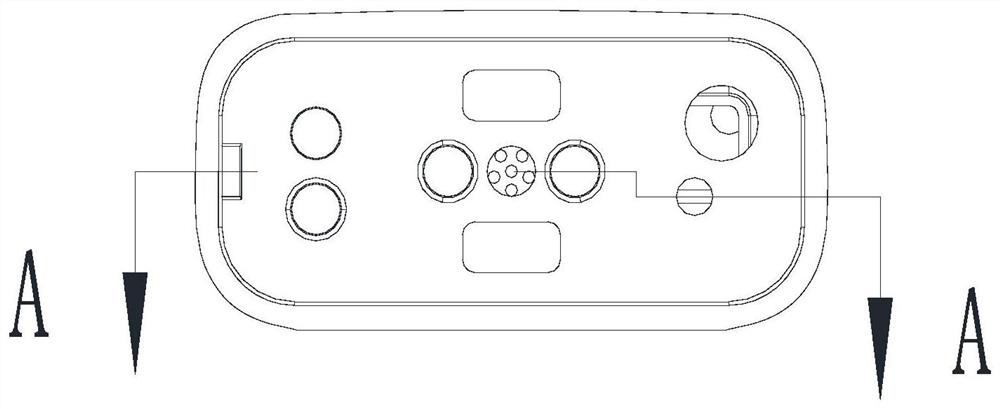

Cigarette cartridge and electronic cigarette

The present invention provides a cigarette cartridge and an electronic cigarette. The cigarette cartridge comprises: an atomizer, wherein the atomizer comprises a supporting base and an atomizing headassembled in the supporting base; a liquid storage cabin which is arranged on the supporting base in a sleeving manner, wherein a tobacco tar cavity is defined between the liquid storage cabin and the supporting base; and a liquid pump which is used for pumping the tobacco tar in the tobacco tar cavity to the atomizing head, and the liquid pump comprises a liquid pumping port, the atomizing headcomprises a bearing part, the bearing part faces the liquid pumping port, and the bearing part is made of a hard material. According to the smoke cartridge and the electronic cigarette, due to the fact that the starting speed of the liquid pump is high, the pressure is high when tobacco tar is pumped, and the bearing part is made of the hard material, it is avoided that when the tobacco tar with the high pressure impacts the bearing part made of the soft material, the atomizing head fails, and liquid leakage is caused.

Owner:CHANGZHOU PATENT ELECTRONICS TECH CO LTD

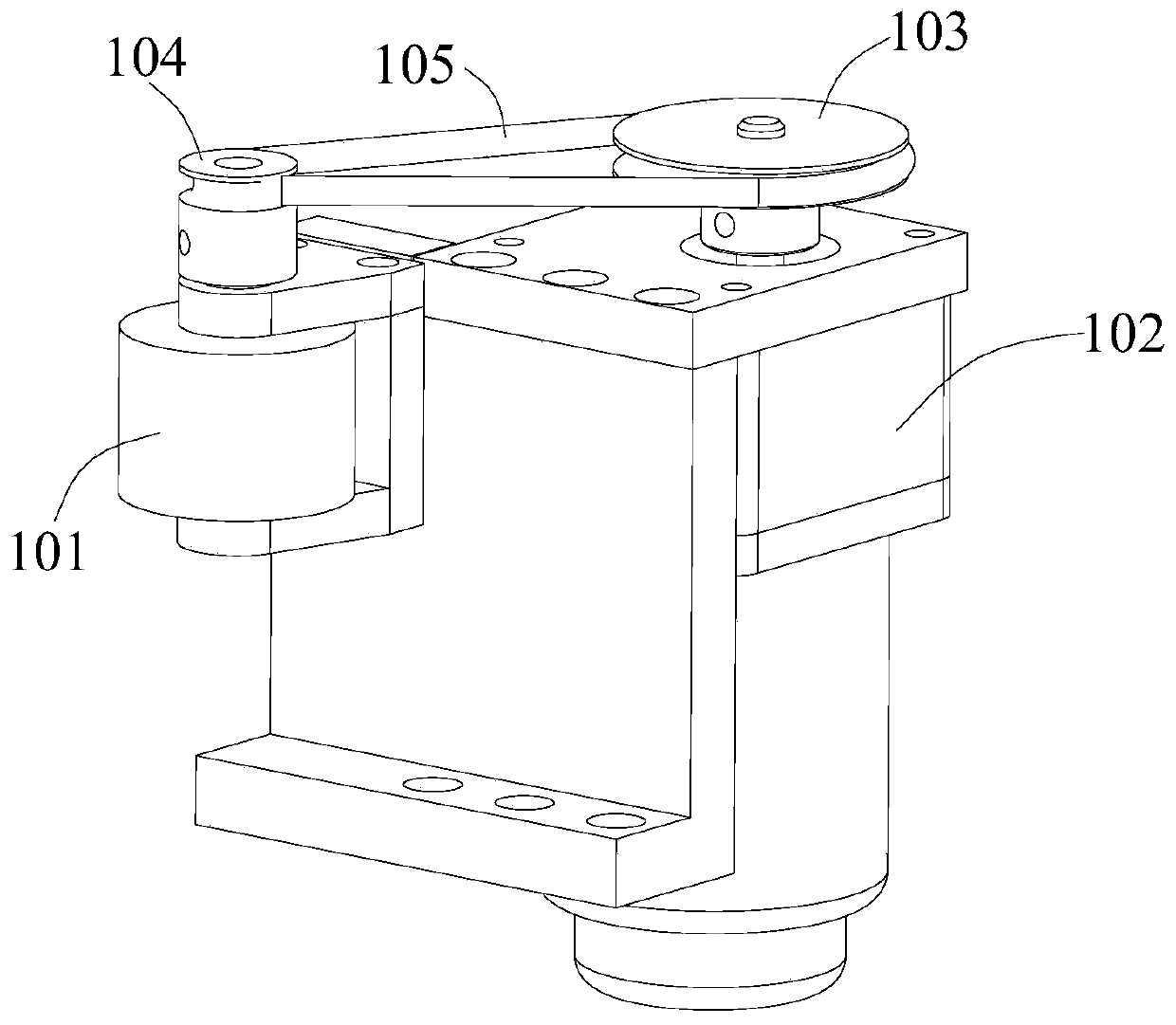

Universal cable payer

ActiveCN108313811BSolve the problem of too fast pay-off speedMeet production speed needsFilament handlingTinningEngineering

The invention belongs to the field of tinned wire production equipment, and particularly relates to a universal paying-off machine. The universal paying-off machine comprises a top plate and a rotarydisk, and the rotary disk and the top plate are connected with each other through a first bearing. A cantilever extending outwards is arranged radially on the disk edge of the rotary disk, and a support arm extending downwards is arranged at the suspension end of the cantilever. A first direction changing wheel is arranged on the support arm and a second direction changing wheel is arranged at thesuspension end of the cantilever. A gantry frame is arranged on the upper disk surface of the rotary disk, and a through hole is formed in a cross beam of the gantry frame in a penetrating mode. A third direction changing wheel is fixedly connected to the lower portion of the cross beam, a reversing frame is arranged on the cross beam in a reversing fit mode, and a rotation axis of the reversingframe is vertically arranged. A guide wheel and a tension adjusting wheel are sequentially arranged on the reversing frame from bottom to top. The universal paying-off machine has the advantages of simple structure, flexible and convenient use and reliable and stable operation, and the high-quality and smooth production of small axes can be realized without changing the production process of an existing wire stranding machine.

Owner:铜陵顶科线材有限公司

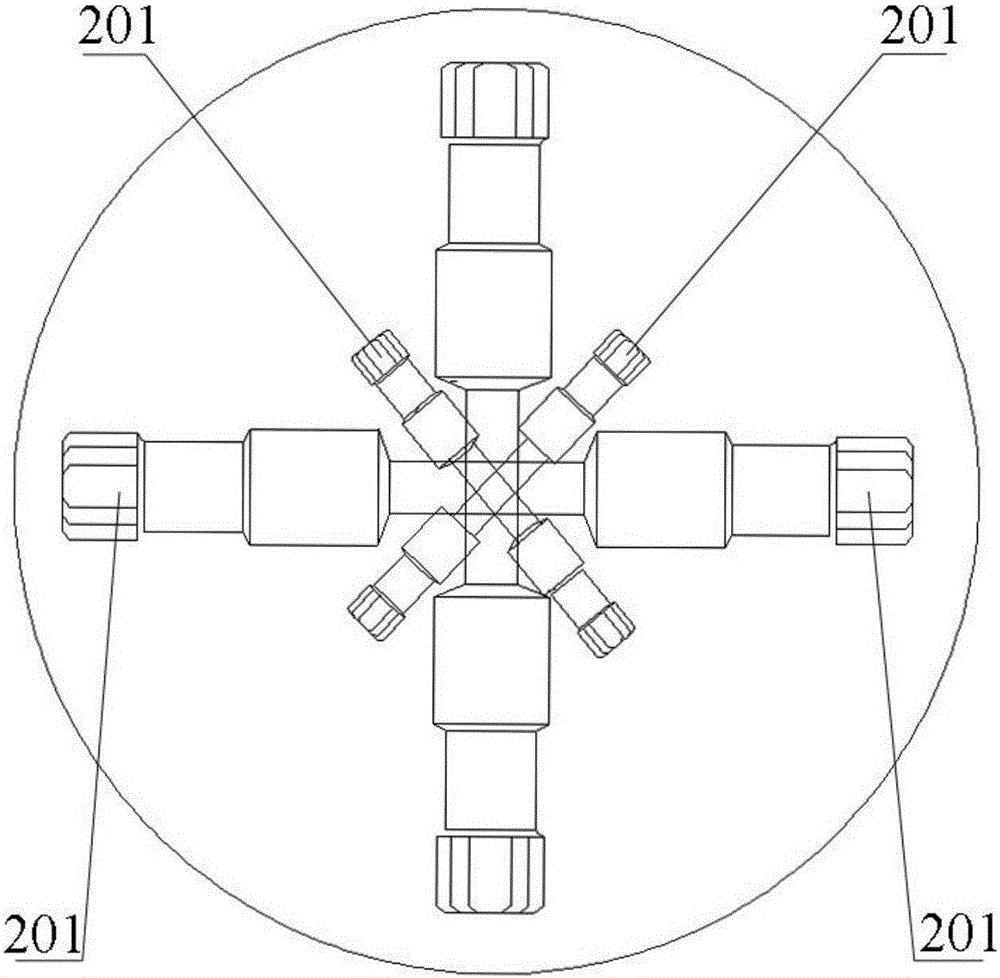

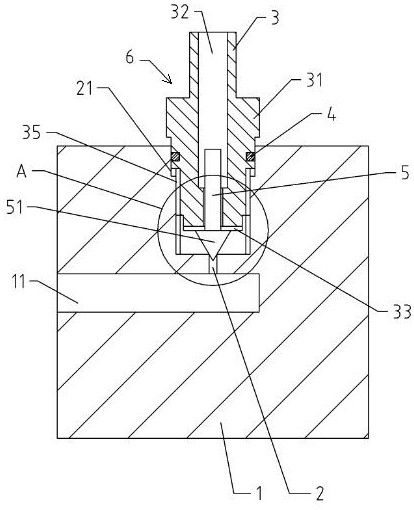

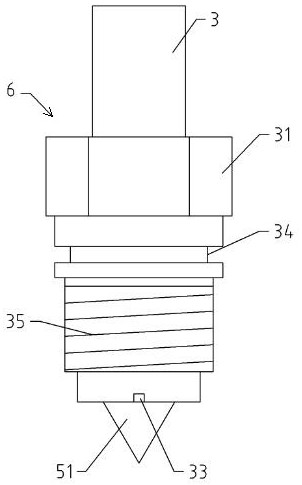

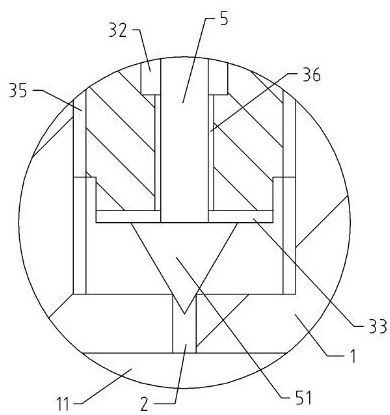

Vacuum exhaust valve and cubic press comprising such vacuum exhaust valve

PendingCN111828435AStrong pressure capacityImprove impact resistanceUltra-high pressure processesLift valveExhaust valveAir pump

The invention relates to the technical field of cubic press, and particularly relates to a vacuum exhaust valve and a cubic press comprising such vacuum exhaust valve. The vacuum exhaust valve comprises an exhaust bolt which is provided with an exhaust hole, a lower part of the exhaust bolt is arranged in the exhaust hole through a thread and an upper part of the exhaust bolt stretches out the exhaust hole and forms an air pumping connector, a valve needle is arranged in the exhaust hole from bottom to top through penetration, the valve needle comprises a guide rod part and a blocking part, anupper end of the blocking part and a lower end face of the exhaust bolt block upwards in cooperation, a lower end blocks downwards and seals a small-diameter end of the exhaust hole, the lower end face of the exhaust bolt is provided with a transverse groove, an inner wall of the exhaust hole is provided with a vertical groove, the transverse groove and the vertical groove are correspondingly communicated so as to form an air channel for gas to flow to an air pumping hole from the exhaust hole. The vacuum exhaust valve provided by the invention has high pressure bearing capability, can adaptto exhaust requirements of an ultrahigh pressure hydraulic system, and simultaneously, is convenient for a vacuum pump to perform vacuum supply for a press cylinder, thus, exhaust efficiency is improved essentially.

Owner:ZHENGZHOU KANGBAITE ULTRAHARD MATERIALS CO LTD

A high-viscosity grease supply pumping system and method

ActiveCN109340546BIncrease viscosityStable pumpingLubricating pumpsLubrication elementsThermodynamicsPetroleum engineering

The invention discloses a high-viscosity lubricating grease supplying and pumping system and method, and relates to the technical field of lubricating grease pumping systems. The high-viscosity lubricating grease supplying and pumping system comprises a grease storing cavity, grease supplying pipelines, a grease supplying pump, a pressurizing part, a heating part, a detecting part and a controller; the grease storing cavity is provided with one or more movable side walls, the input end of the grease supplying pump is connected to the grease storing cavity through the corresponding grease supplying pipeline, and an outlet of the grease supplying pump is externally connected to a distributor through the corresponding grease supplying pipeline; and the output end of the pressurizing part pushes the one or more movable side walls of the grease storing cavity in an abutting mode, and all or one section of the grease supplying pipeline between the grease storing cavity and the grease supplying pump is wrapped with the heating part. Lubricating grease can be heated and pressurized before entering the grease supplying pump, the viscosity of the high-viscosity lubricating grease is improvedthrough heating, the liquidity of the high-viscosity lubricating grease is improved, the effect of grease supplying pump evacuation caused by the insufficient inlet pressure in the pumping process ofthe lubricating grease is avoided through pressurizing, and finally the high-viscosity lubricating grease is pumped stably and reliably.

Owner:ANHUI POLYTECHNIC UNIV

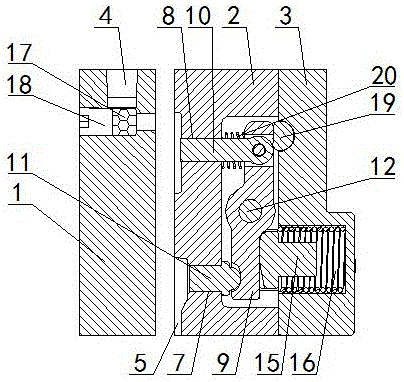

Pressure relief protection gear pump, manufacturing method and pressure relief protection method of pressure relief protection gear pump

ActiveCN105257534AExtended service lifeReduce volumeRotary piston pumpsRotary piston liquid enginesGear pumpEngineering

The invention relates to a pressure relief protection gear pump, a manufacturing method and a pressure relief protection method of the pressure relief protection gear pump. The pressure relief protection gear pump comprises a pump cavity which is internally provided with a driving gear and a driven gear, the driving gear and the driven gear are meshed with each other, and the portion, located on the top of the driving gear and the driven gear, of the pump cavity is provided with a floating valve which can be bounced off under the overload condition to relieve pressure. The pressure relief method of the gear pump includes the steps that when fluid entering the pump cavity causes the situation that the pump cavity pressure exceeds the elastic force of the floating valve, a valve piece is jacked up, and vacuum in the pump cavity disappears; and secondly, the fluid of the pump cavity flows back along an inlet of the pump cavity, and therefore the pump cavity pressure is released, and when the pump cavity pressure is smaller than the elastic force of the floating valve, the valve piece resets. The pump cavity has the self-protecting function; when the pressure in the pump cavity is overloaded, it is guaranteed that the floating valve piece can be bounced off to relieve pressure, and accidents of pump burst or motor burnout caused by overpressure can be avoided. By means of the manufacturing method, the technological process of production of the gear pump can be simplified so that cost can be reduced.

Owner:广东时光电子有限公司

A kind of environment-friendly and easily decomposable vegetable oil-based lubricating oil and its production process

ActiveCN104745280BMeet actual use needsProduce pollutionLubricant compositionVegetable oilSunflower oil

The invention discloses an environmentally friendly and easily decomposable vegetable oil-based lubricating oil and a production process thereof, belonging to the field of lubricating oil. The lubricating oil of the present invention adopts vegetable oil as the base oil, and the mass ratio of the base oil and the additive is 7:3, wherein the base oil includes high oleic sunflower oil and castor oil, and the quality of the high oleic sunflower oil and castor oil is The ratio is 6:4. Among them, high oleic sunflower oil, with an oleic acid content of up to 90%, has extremely high antioxidant properties, while castor oil has an ideal viscosity. The two are used in a ratio. As an ideal vegetable oil, no special processing is required. Advantageous characteristics of conventional mineral oils as base oils. In addition, through the auxiliary modification of additives, no special processing is required, and it can be put into use after simple proportioning and high-temperature smelting. The production cost is low and it is easy to popularize.

Owner:HANERGY (QINGDAO) LUBRICATION TECH CO LTD

Concrete pump with lifting type hopper fence

InactiveCN106564123AEasy to replaceReduce manufacturing costMixing operation control apparatusPumpsEngineeringMechanical engineering

The invention discloses a concrete pump with a lifting type hopper fence. The concrete stacking problem is thoroughly solved. The concrete pump comprises a concrete stirring device, a hopper, a fence and a machine frame. An installation frame is fixed to one side of the machine frame. A lifting driving device is fixed to the installation frame. An installation plate is fixed to the lower end of a lifting rod of the lifting driving device. A vibration device is fixed to the installation plate. The vibration device comprises a pneumatic vibrator and a vibrator clamping device. The vibrator clamping device is provided with multiple guide rod through holes. Clamping device guide rods are arranged in the guide rod through holes correspondingly in a sliding fit mode. The upper extending end and the lower extending end of each clamping device guide rod are sleeved with compression springs correspondingly. The lower end of each clamping device guide rod is fixedly connected with the installation plate.

Owner:重庆华耀混凝土有限公司

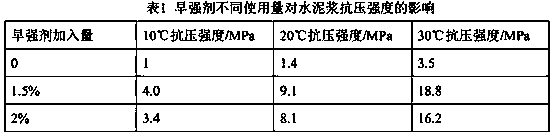

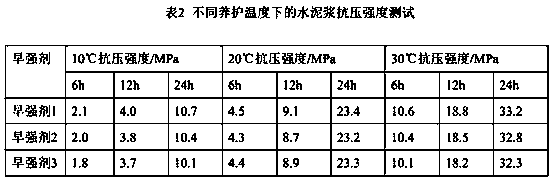

A low-temperature cement early strength agent for well cementing and cement containing it

ActiveCN107540260BImprove early strength performanceIncreased durabilityDrilling compositionSodium sulfateWater reducer

The invention discloses a low-temperature cement early strength agent used for well cementation and cement containing the low-temperature cement early strength agent and relates to the technical fieldof cement additives. The low-temperature cement early strength agent is prepared from, by weight, 23-27 parts of sodium sulfate, 5-7 parts of sodium nitrate, 3-5 parts of ferrous sulfate, 0.2-0.3 part of diethanol amine, 0.4-0.5 part of triethanolamine, 1.0-1.3 parts of water reducer, 2-2.5 parts of micro-fine mica powder, 0.3-0.5 part of lithium carbonate and 0.8-1.0 part of talcum powder. The early strength agent has excellent low-temperature early strength and compressive strength, is capable of meeting the requirements for low-temperature deepwater well cementation, the time for waiting for cementation is shortened, the working efficiency and the safety are improved. The early strength agent is a chloride-free early strength agent, and in use, the early strength agent is good in flowability, the flash cementation phenomenon does not occur, and the early strength agent has no corrosive effect on a casing.

Owner:YINGKOU HONGXIN MATERIALS SCI & TECH

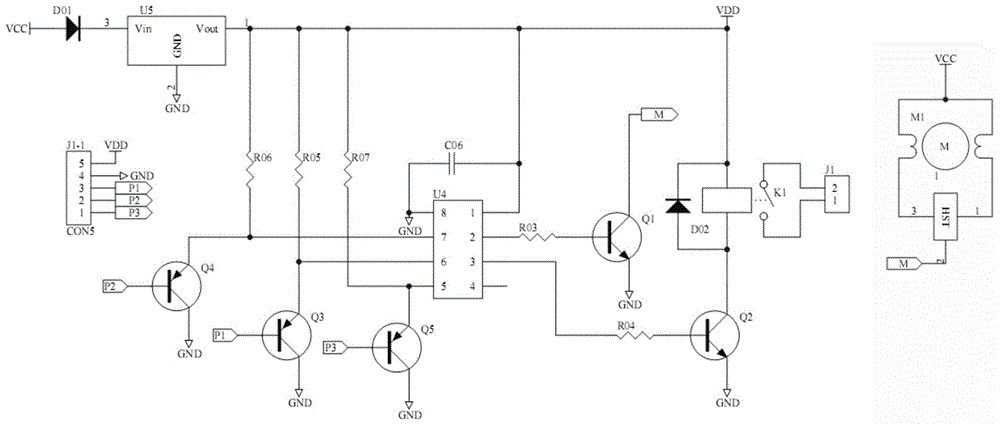

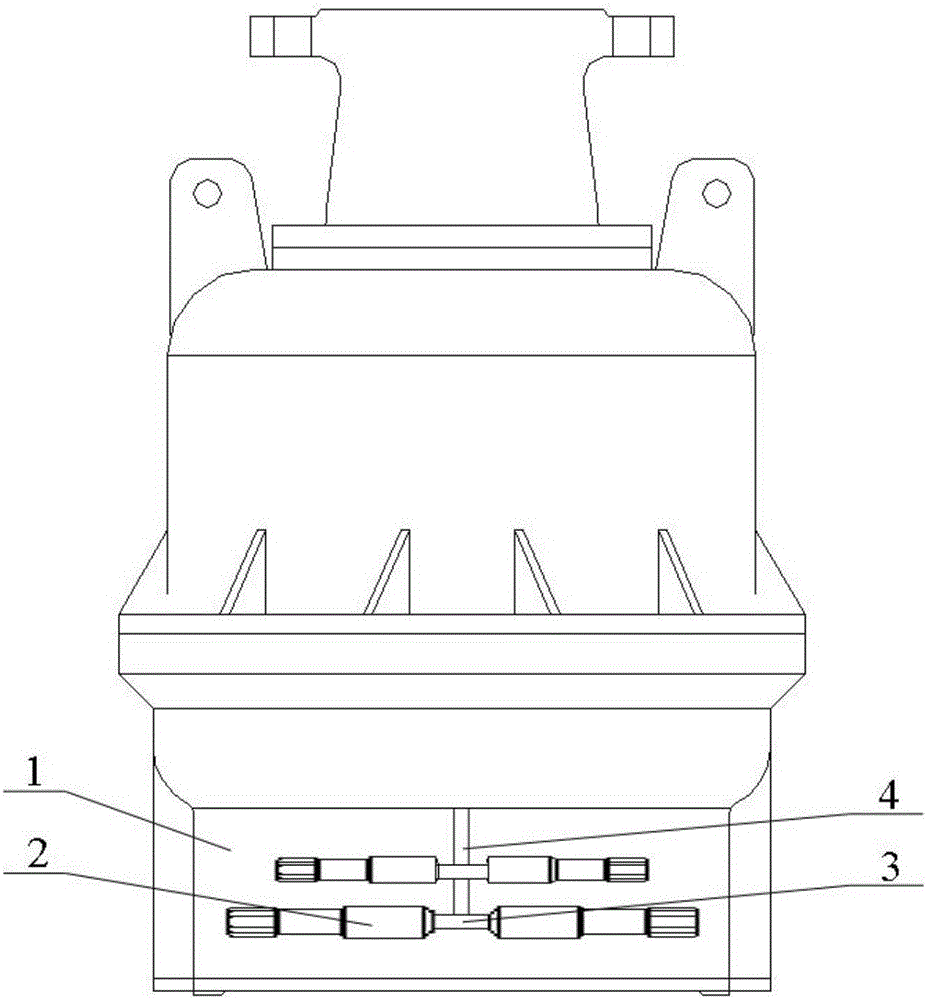

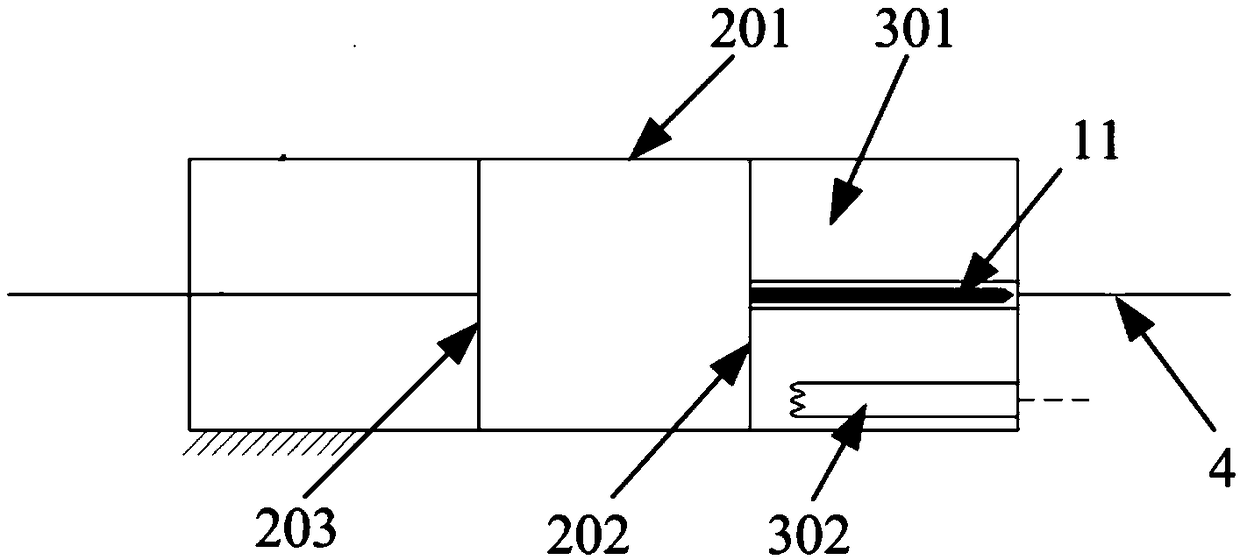

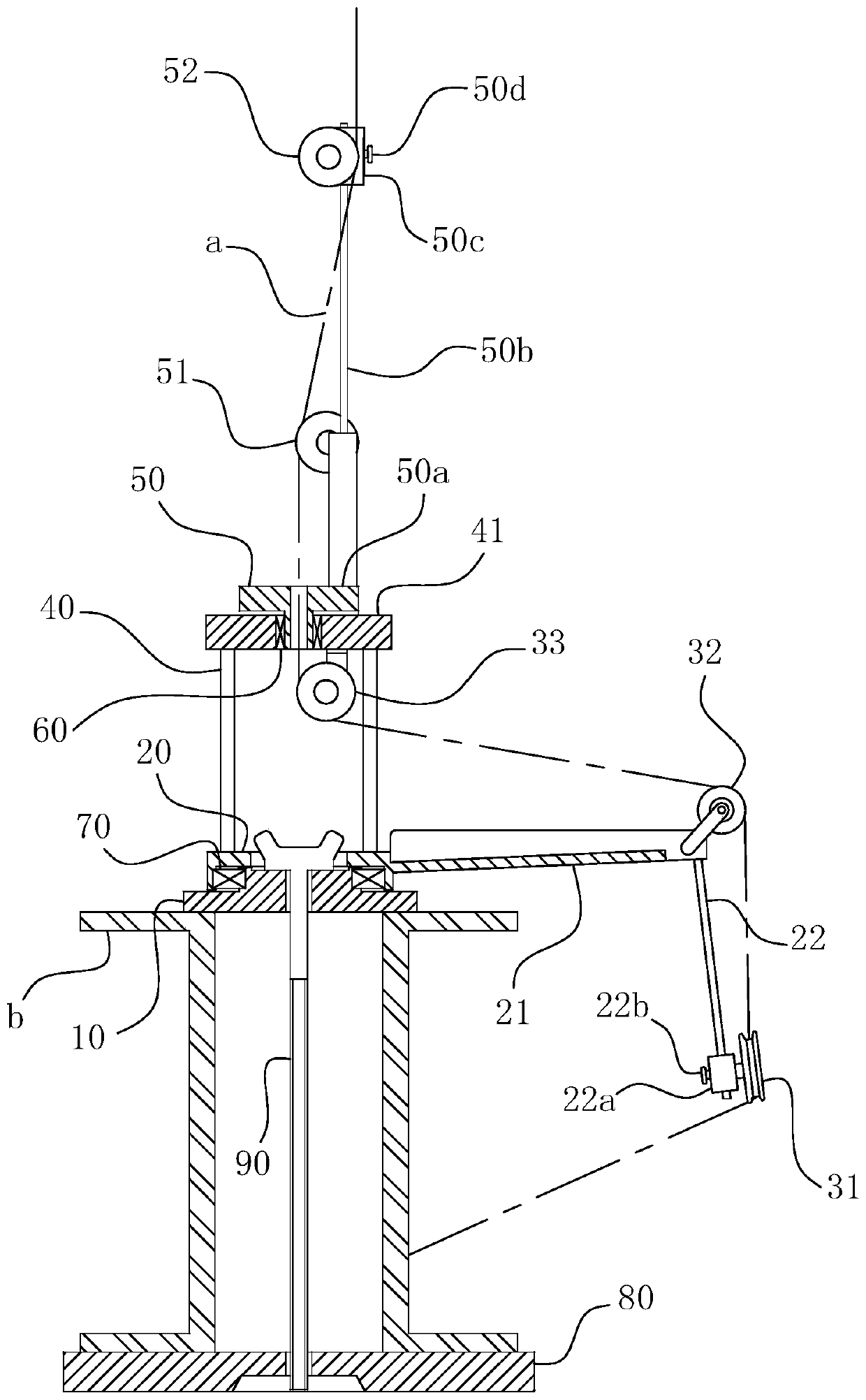

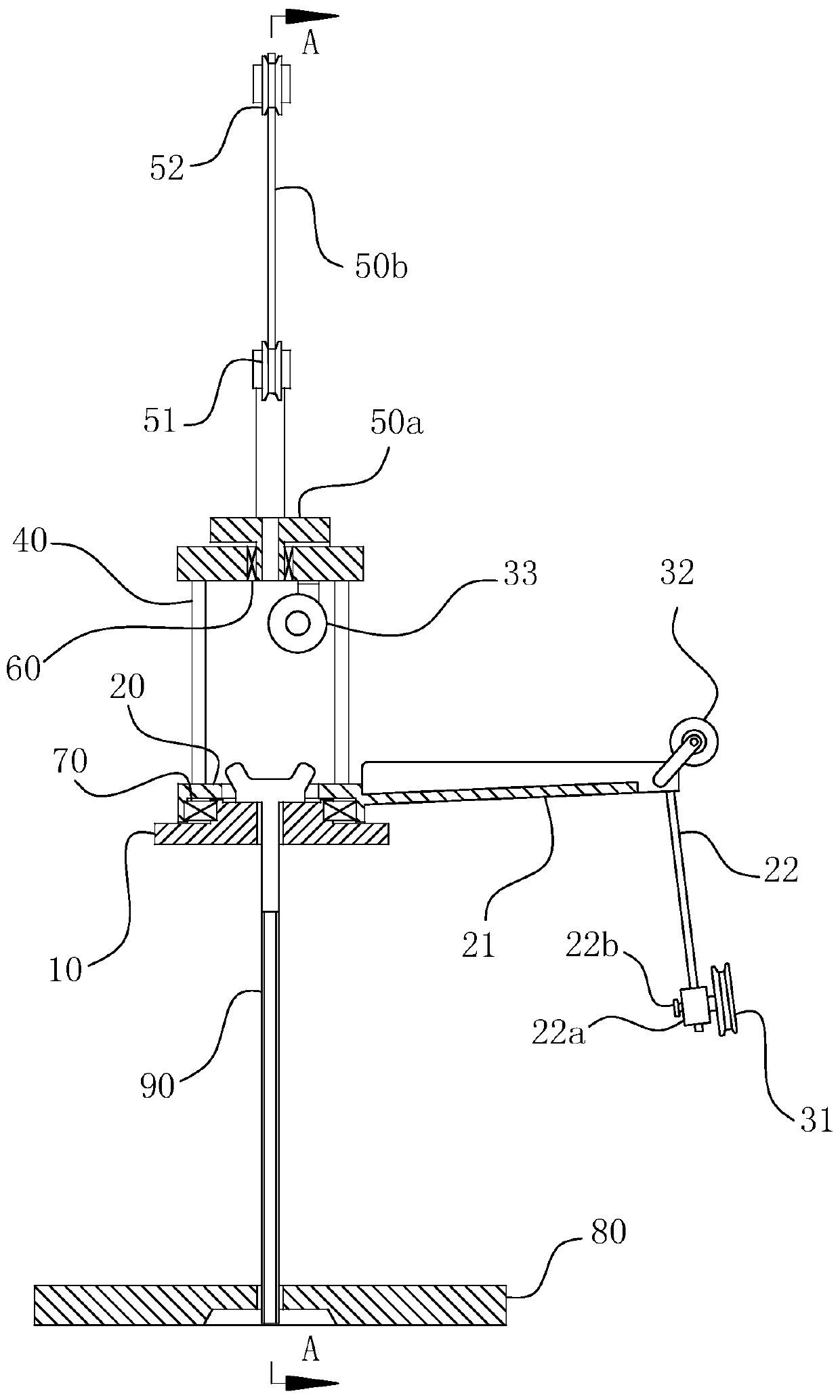

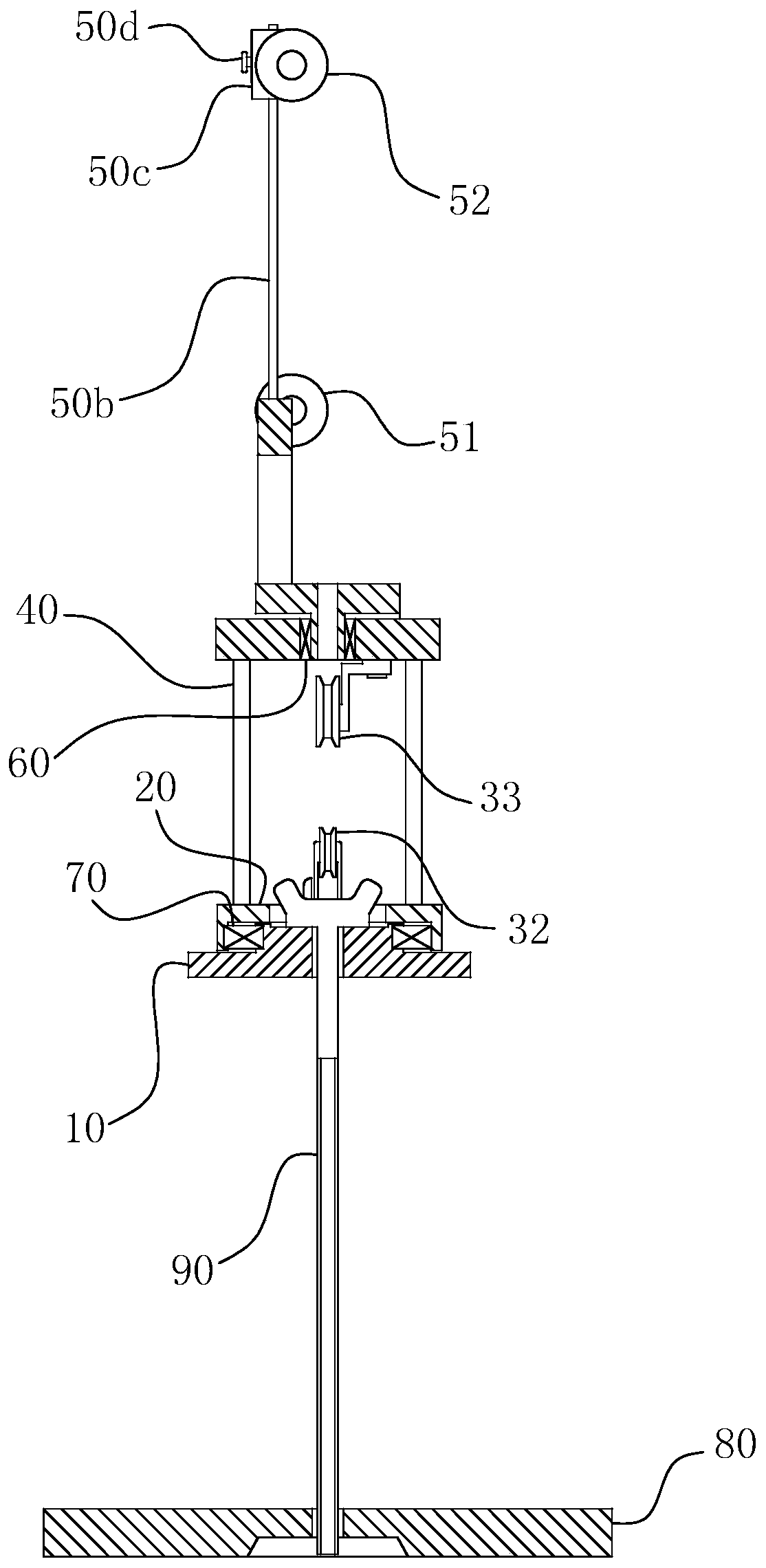

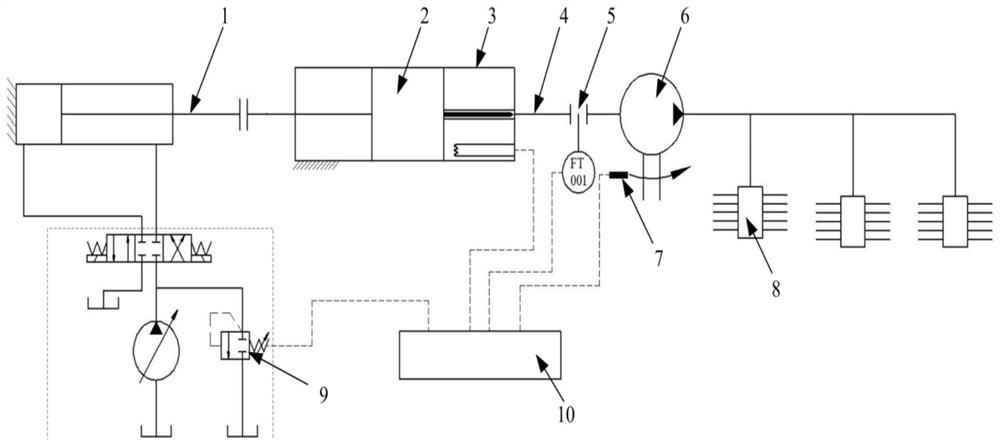

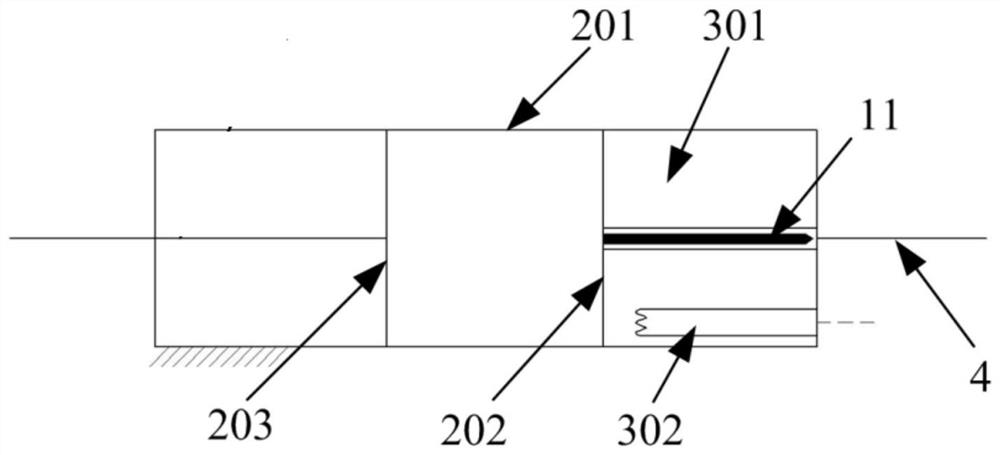

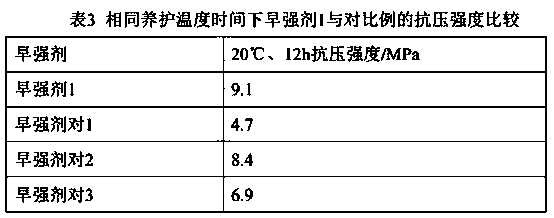

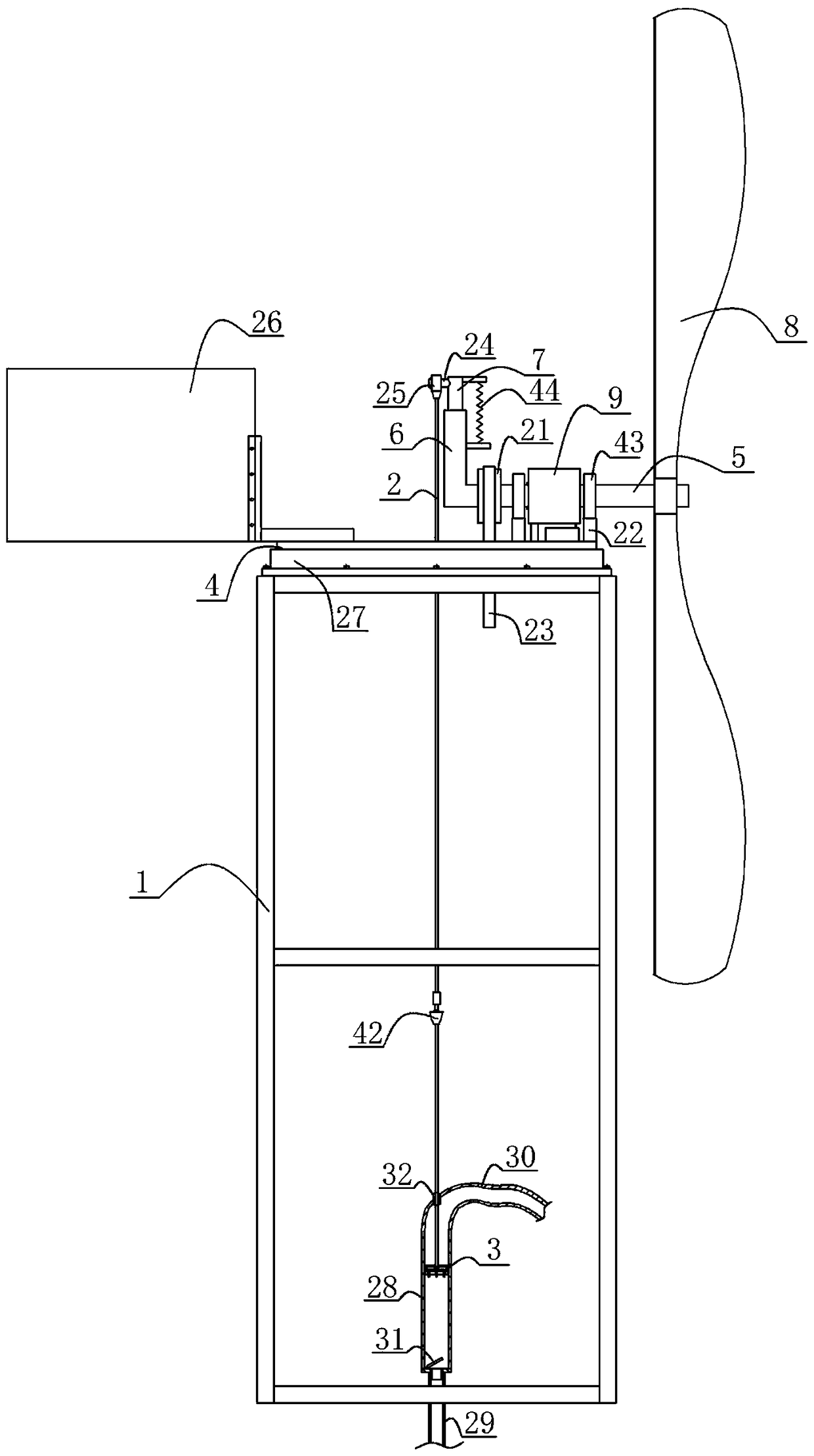

A wind pumping system

InactiveCN106593805BSmooth pumpingGood effectEnergy industryPump controlImpellerReciprocating motion

The invention discloses a wind-power water pumping system. The wind-power water pumping system comprises a machine frame, a pull rod, a piston, a cylinder body and a wind power conversion mechanism, and is characterized in that the wind power conversion mechanism is composed of a bottom plate, a rotating shaft, a first oil cylinder and / or a second oil cylinder, a telescopic rod, an impeller and a wind power adjusting mechanism; the rotating shaft is arranged on the rotatable bottom plate; the lower end of the telescopic rod is fixed to the first oil cylinder; the pull rod is connected with the upper end of the telescopic rod; and the wind power adjusting mechanism adjusts the telescopic length of the telescopic rod according to the current wind speed so as to control the water pumping frequency and the stroke of the pull rod. According to the wind-power water pumping system, when the external wind speed is low, the stretching length of the telescopic is small, when the wind speed is high, the stretching length of the telescopic is large, and the pull rod conducts water pumping operation at the large stroke and the high speed; and as the magnitude and the speed, formed through water pumping, of the reacting force forces the speed of the impeller to be stable relatively, the piston at the lower end of the pull rod can move up and down in a reciprocating mode at the relatively stable speed regardless of the magnitude of the wind speed, and steady water pumping operation is conducted.

Owner:张正泉

Sewage pumping device of lead paste mixing machine

PendingCN114405382AAffects flip actionGuaranteed stabilityTransportation and packagingMixer accessoriesSewageMechanical engineering

The invention provides a sewage pumping device for a lead plaster mixing machine, and belongs to the field of storage battery lead plaster mixing machines, an opening can be opened by turning a sealing cover leftwards, and a hinged water pumping cover is arranged to turn the opening leftwards, so that a water pumping hose enters the lead plaster mixing machine to pump water; the water pumping pipe and the paste mixing machine body are fixed in position through a threaded connection mechanism, the water pumping hose is fixed to the water pumping cover through a limiting mechanism, and the sealing cover and the paste mixing machine body are fixed in position through a hook ring mechanism, so that the position of the water pumping cover and the position of the water pumping hose are fixed in the water pumping process, and the stability of the water pumping process can be guaranteed; and the position of the sealing cover is fixed, so that the sealing cover does not move randomly to influence the overturning action of the water pumping cover, and the problem that the paste mixer is inconvenient to pump water is solved.

Owner:TIANNENG BATTERY WUHU

Automatic water level control pump

ActiveCN104612980BReduce frequent starting problemsEasy to installPump controlPump installationsImpellerAutomatic control

Owner:深圳市钜泰泵业有限公司

Colloidal emulsion explosive for underground mining and preparation method thereof

ActiveCN108640806BImprove liquidityEasy to automate pumpingNon-explosive fillers/gelling/thickening agentsExplosive ingredient compoundingExplosive AgentsDetonation

Owner:ANHUI UNIV OF SCI & TECH

Pressure relief protected gear pump, manufacturing method and pressure relief protection method thereof

ActiveCN105257534BRelieve pressureExtended service lifeRotary piston pumpsRotary piston liquid enginesRefluxSpring force

The invention relates to a pressure relief protection gear pump, a manufacturing method and a pressure relief protection method thereof; the pressure relief protection gear pump includes a pump cavity, and a driving gear and a driven gear are arranged in the pump cavity to mesh with each other, and are located between the driving gear and the driven gear. The pump chamber at the top of the moving gear is provided with a floating valve that can be popped open for pressure relief when overloaded. The pressure relief protection method of the gear pump includes: (1) When the fluid entering the pump chamber causes the pressure in the pump chamber to exceed the elastic force of the floating valve, the valve is lifted to make the vacuum in the pump chamber disappear; (2) The fluid in the pump chamber moves along the pump chamber The inlet backflow, thereby releasing the pump chamber pressure, when the pump chamber pressure is less than the elastic force of the float valve, the valve will reset. The pump cavity of the present invention has a self-protection function. When the pressure in the pump cavity is overloaded, the floating valve plate can be popped open to release the pressure, so as to avoid accidents of pump burst or motor burnout caused by overpressure. This manufacturing method can reduce gear pump pressure. The technological process of production reduces the cost.

Owner:广东时光电子有限公司

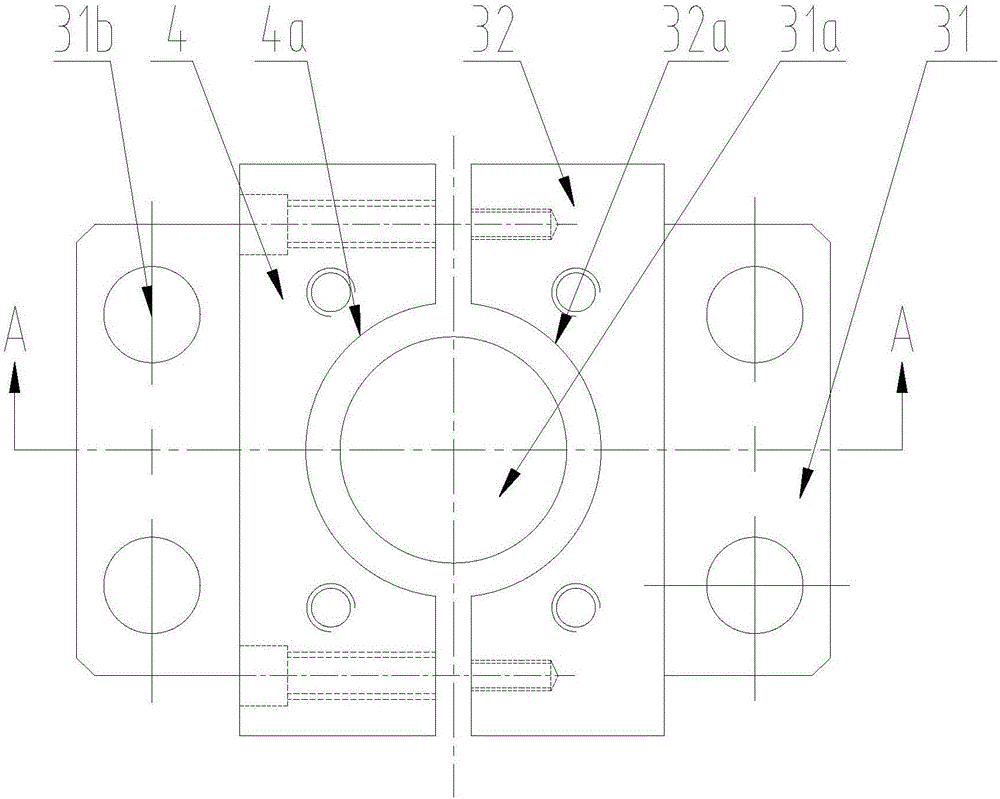

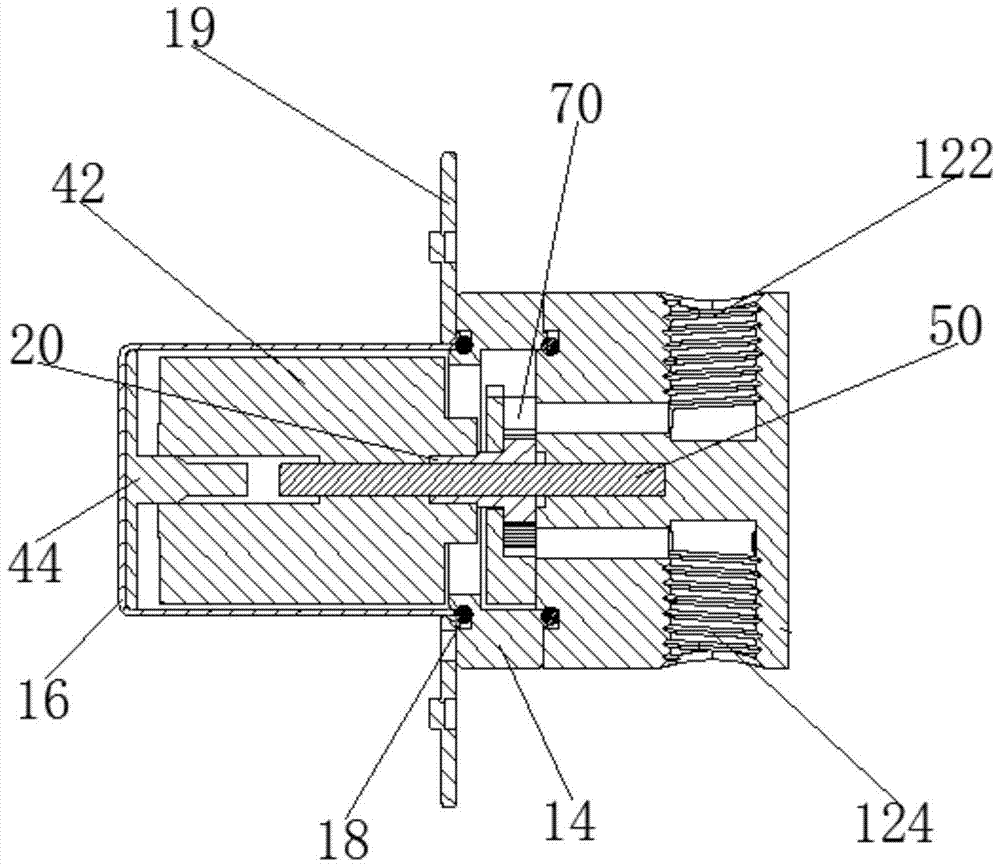

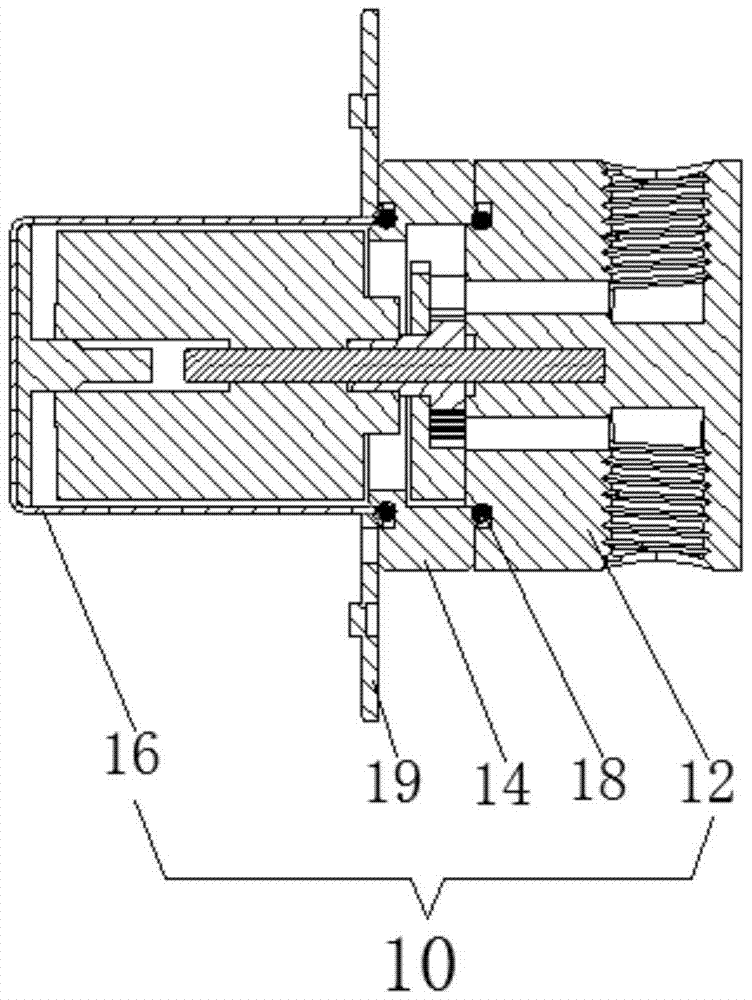

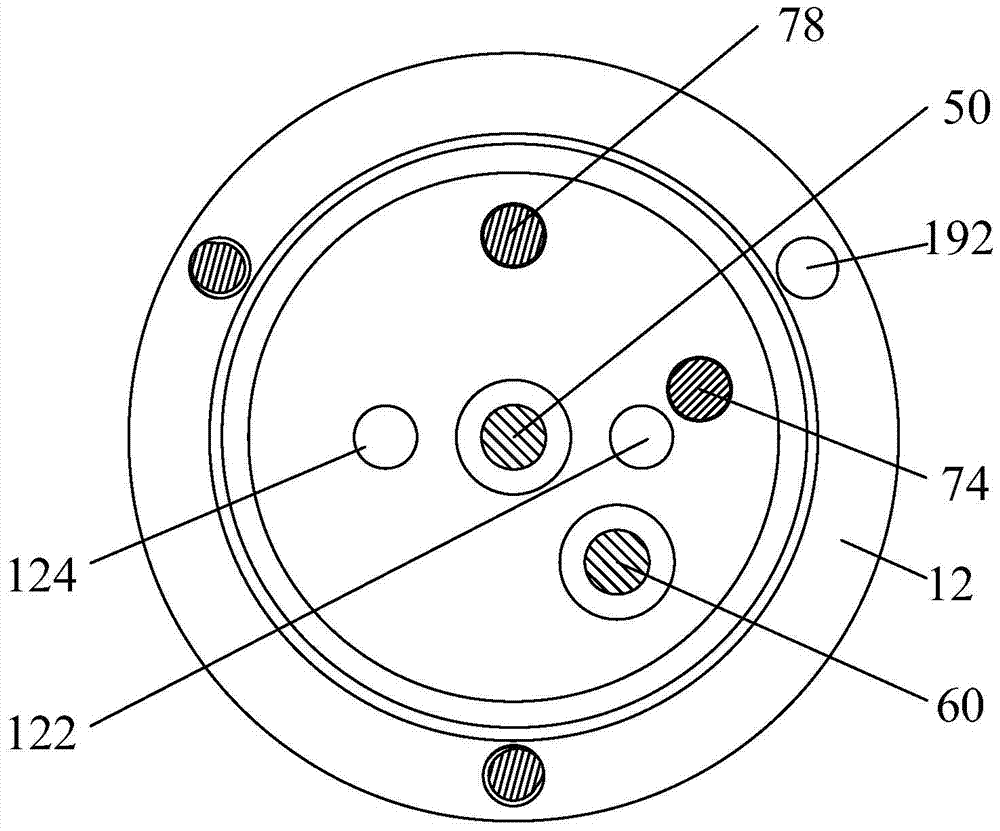

A vacuum pumping valve for die-casting mold

The invention discloses a vacuum extraction valve used on a die-casting die. The vacuum extraction valve comprises a moving valve body, a stationary valve body and a backboard, the stationary valve body is located between the moving valve body and the backboard, and an L-shaped exhaust duct is arranged on the upper portion of the moving valve body; a cavity provided with a feeding port is formed in the end face of the stationary valve body, a linkage mechanism used for controlling gas to enter and exit is arranged inside the stationary valve body, the linkage mechanism is matched with a pressure hole and an exhaust hole formed inside the cavity, and the exhaust duct corresponds to the upper end of the cavity; an ejection mechanism is arranged on the backboard, the front end of the ejection mechanism penetrates into the stationary valve body, and the linkage mechanism is located in the ejection mechanism. The vacuum extraction valve has the advantages of being ingenious in structural design and low in cost, the vacuum extraction valve enables the die-casting die to extract air smoothly in the production process, the fabrication process of the vacuum extraction valve is simple, and the maintenance cost is low.

Owner:CHONGQING DONGKE MOLD MFG

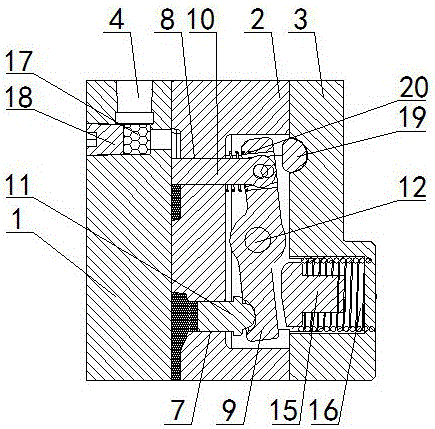

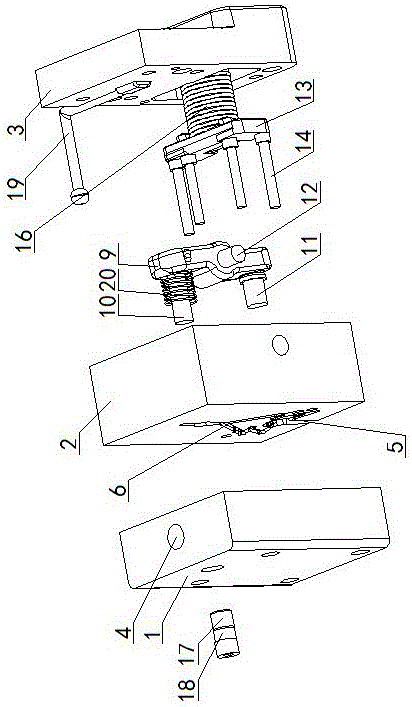

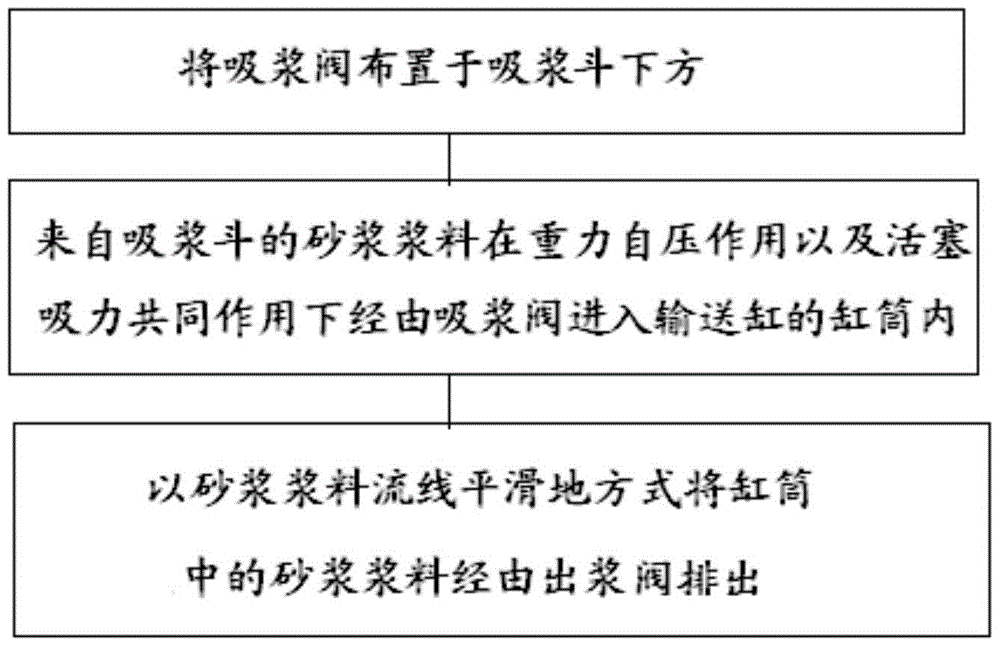

Method of gravity self-pressurization anti-segregation pumping high sand rate ready-mixed mortar

ActiveCN104631830BNot easy to segregateImprove suction capacityBuilding material handlingSuction stressDual action

A method for pumping high-sand-rate premixed mortar in a gravity self-pressure separation prevention mode comprises the steps that a mortar suction valve is arranged below a mortar suction hopper; mortar materials from the mortar suction hopper enter a cylinder tube of a conveying cylinder through the mortar suction valve under the mutual action of the gravity self-pressure and the suction force of a piston; the mortar materials in the cylinder tube are smoothly discharged through a mortar outlet valve in the mortar material flowing line direction, wherein the mortar outlet valve and the conveying cylinder are in the same direction, the discharging direction of the mortar materials is straight, and the flow direction is basically not changed. According to the method, the mortar suction valve is arranged below the mortar suction hopper, the mortar can be directly sucked from the bottom of the hopper, the mortar materials enter the cylinder tube under the double action of the gravity self-pressure and the suction force of the piston, the mortar suction resistance is greatly reduced, separation is not likely to happen in the mortar suction-in process, the mortal materials which are low in fluidity or include large aggregates can be sucked in, and the mortar suction capability is greatly improved.

Owner:WUHAN ORIENT CONSTR GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com