Oil feeder for lubricant in reciprocal movement type compressor

A technology of reciprocating motion and oil supply device, which is applied to the components of pumping devices for elastic fluids, machines/engines, liquid variable capacity machines, etc., and can solve the problems of contamination of refrigerant gas, degradation of lubricating performance, foreign matter, etc. , to prevent contamination of lubricating oil, improve oil supply performance, and prevent wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The lubricating oil supply device for a reciprocating compressor of the present invention will be described in detail below with reference to the examples shown in the accompanying drawings.

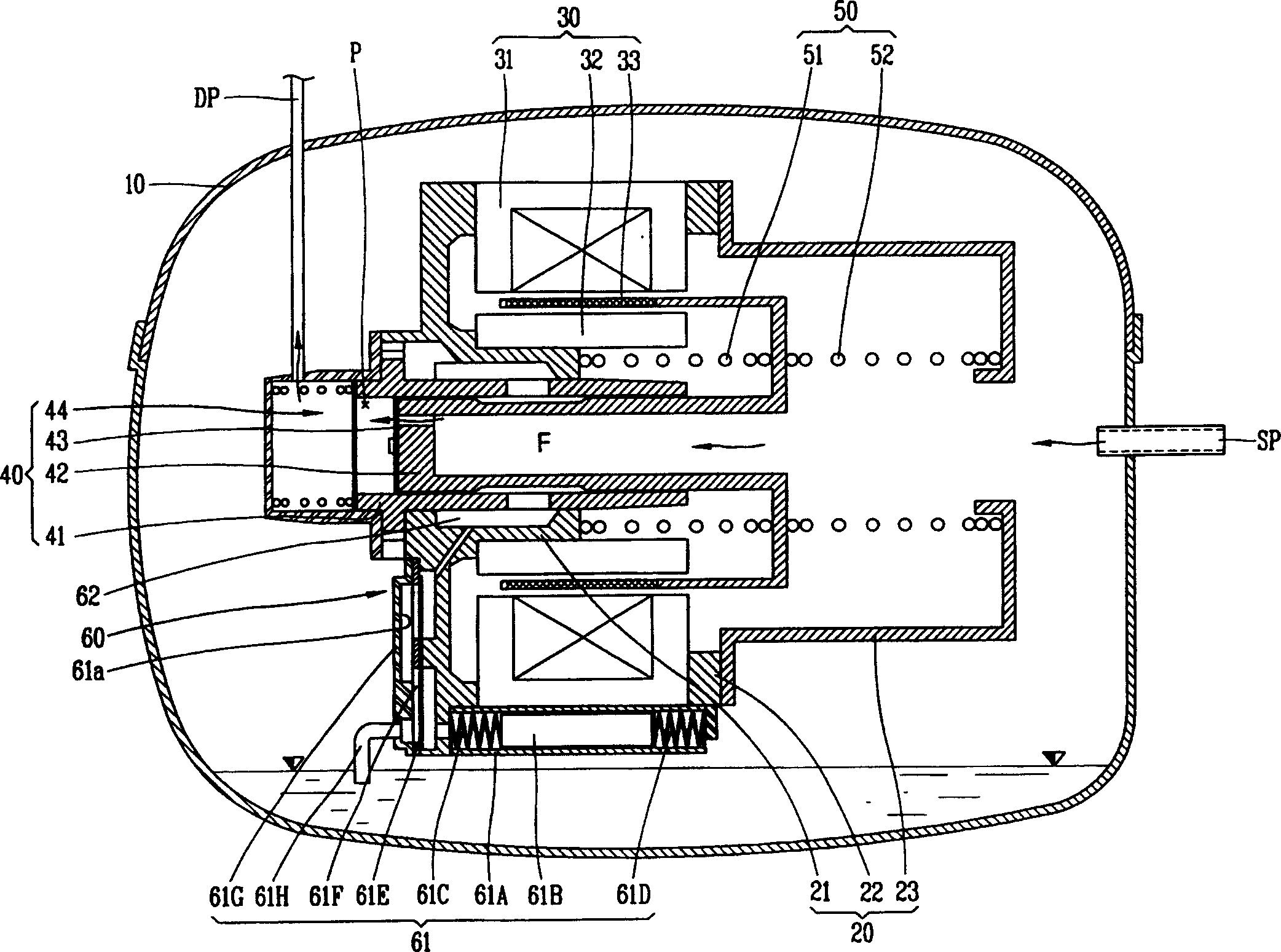

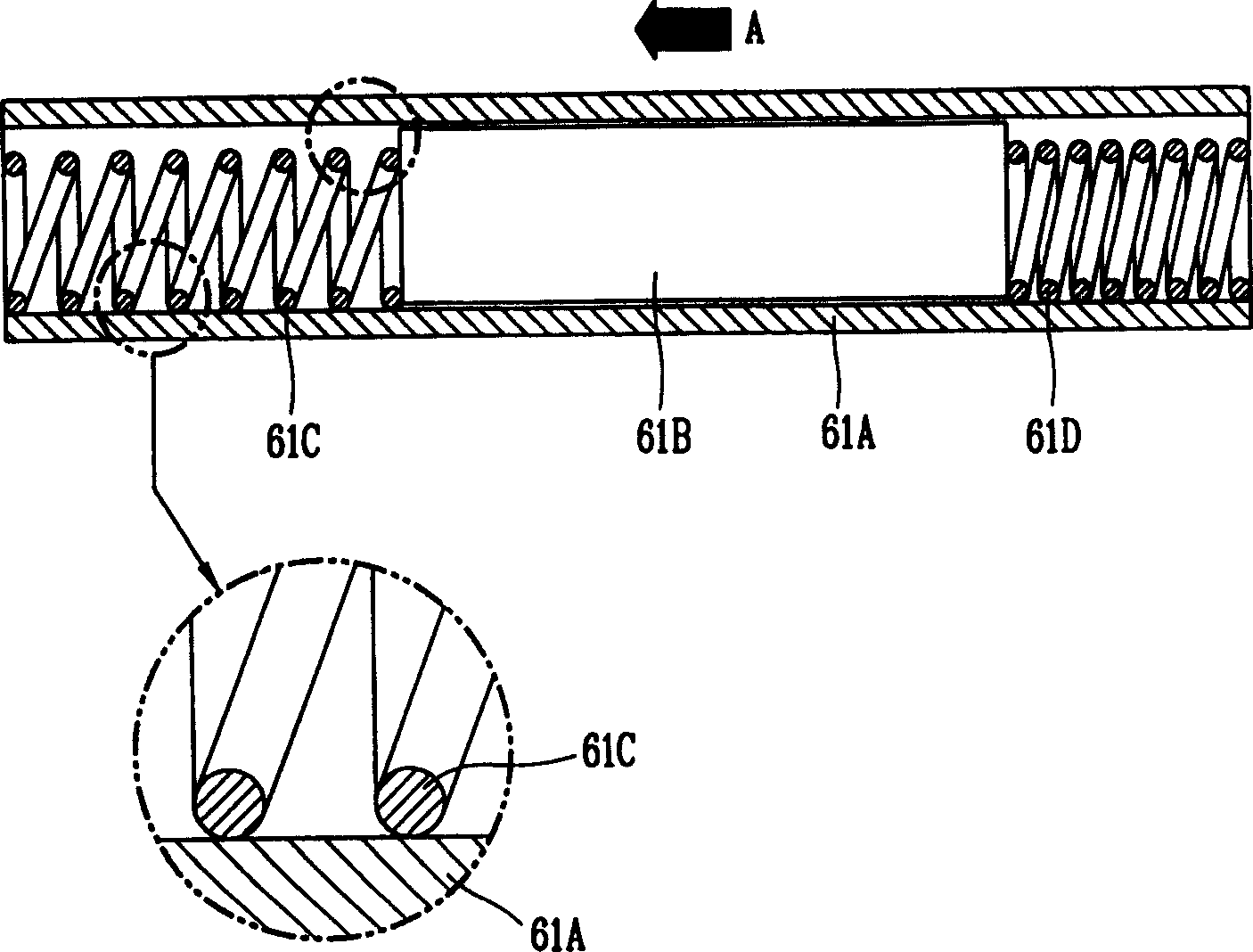

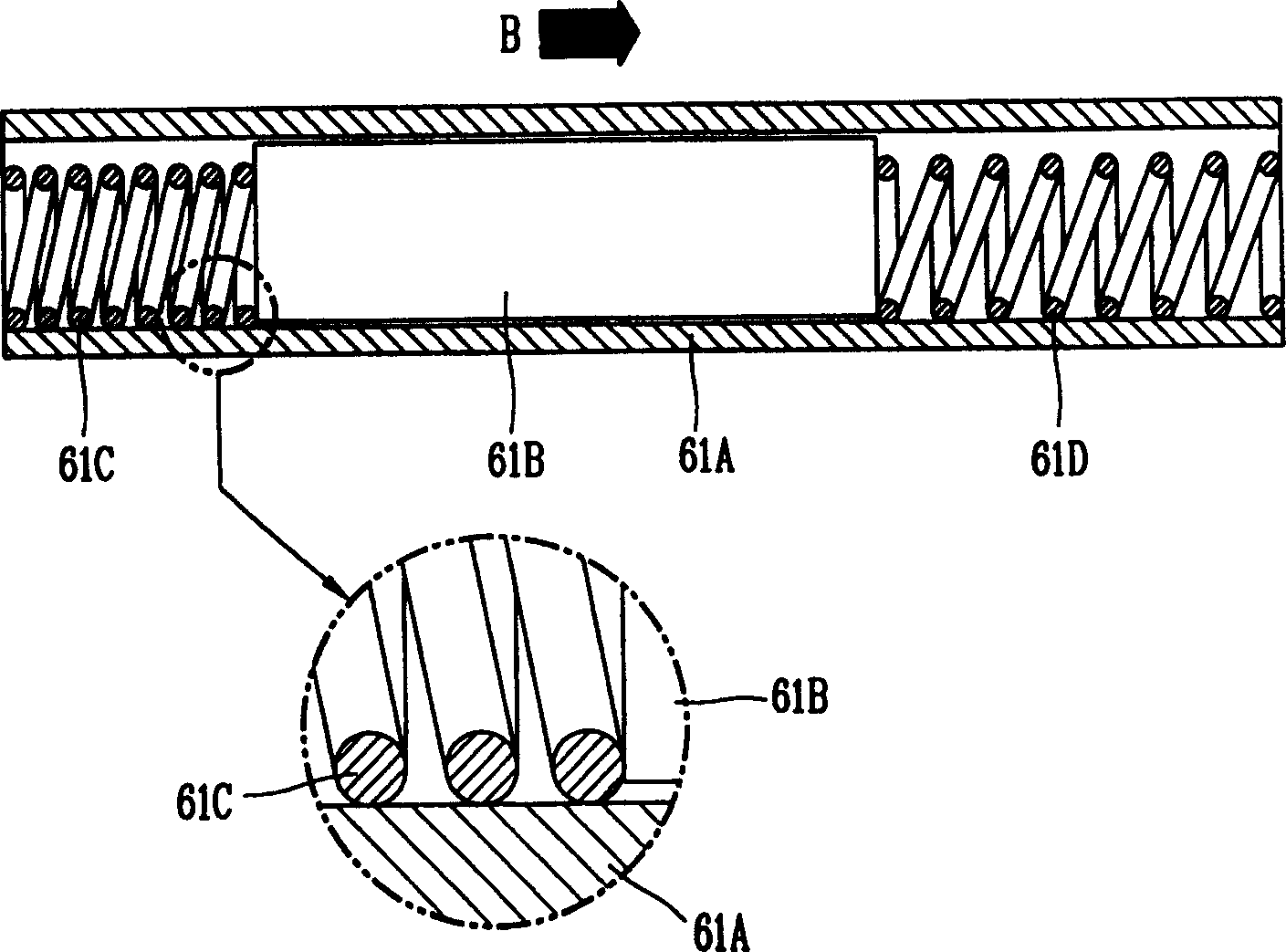

[0037] image 3 is a longitudinal sectional view of an example of the reciprocating compressor of the present invention, Figure 4a and Figure 4b It is a longitudinal sectional view of the operating state of the lubricating oil supply device of the present invention, Figure 5 It is a longitudinal sectional view of a modified example of the lubricating oil supply device of the present invention.

[0038] As shown in the accompanying drawings, the reciprocating compressor equipped with the lubricating oil supply device of the present invention is composed of the following parts, namely: the casing 10, which contains a certain amount of lubricating oil; the frame assembly 20, which maintains a certain degree of elasticity. Installed inside the casing 10; the reciprocating motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com