A vacuum pumping valve for die-casting mold

A technology of die-casting molds and air extraction valves, which is applied in the field of vacuum air extraction valves, can solve the problems of complex maintenance, unclean air extraction, and inability to seal water, etc., and achieves the effects of simple manufacturing process, ingenious structural design, and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

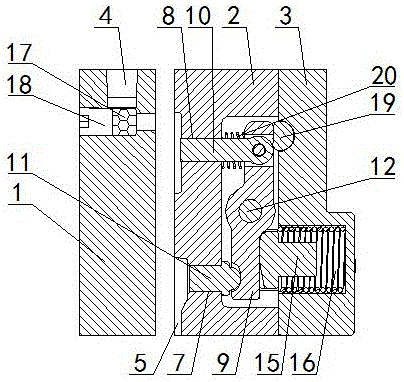

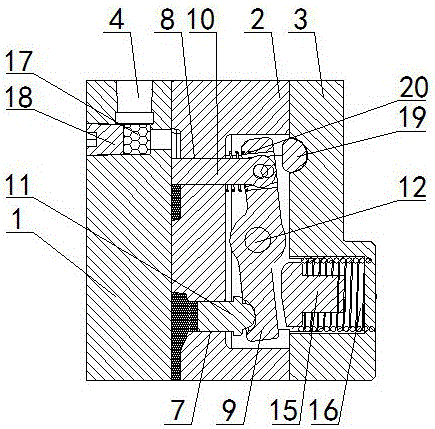

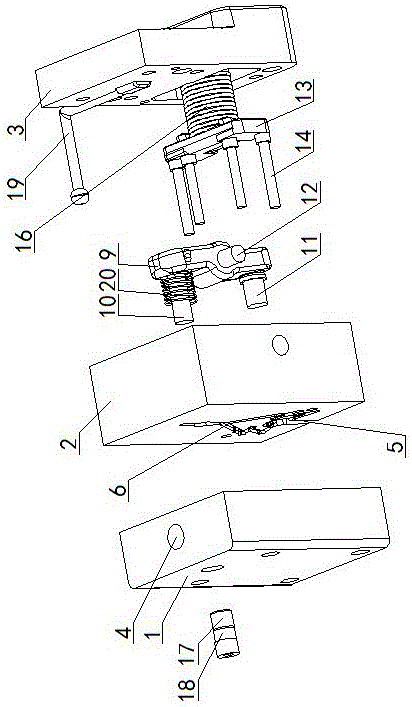

[0016] Embodiment 1: as figure 1 , 2 , 3, a vacuum pumping valve for die-casting molds, the vacuum pumping valve includes a moving valve body 1, a static valve body 2 and a back plate 3, the static valve body 2 is located on the moving valve body 1 Between and the back plate 3, an L-shaped exhaust channel 4 is provided on the upper part of the movable valve body 1; a cavity 6 with a feed port 5 is provided on the end face of the static valve body 2, and a The valve body 2 is provided with a link mechanism for controlling gas in and out, and the link mechanism is matched with the pressure hole 7 and the exhaust hole 8 arranged in the cavity 6, and the exhaust channel 4 is connected with the cavity 6 corresponds to the upper end; a ejection mechanism is provided on the back plate 3, the front end of the ejection mechanism penetrates into the static valve body 2, and the linkage mechanism is located between the ejection mechanisms.

[0017] Wherein, the above-mentioned link mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com