Universal cable payer

A pay-off and wire reel technology, which is applied in thin material handling, delivery of filamentous materials, transportation and packaging, etc., can solve the problems of fast take-up speed of small axis, easily disordered wire unwinding, interruption of wire supply process, etc. , to achieve the effect of high online tension adjustment efficiency, no messy thread draw-out line, and stable draw-out line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

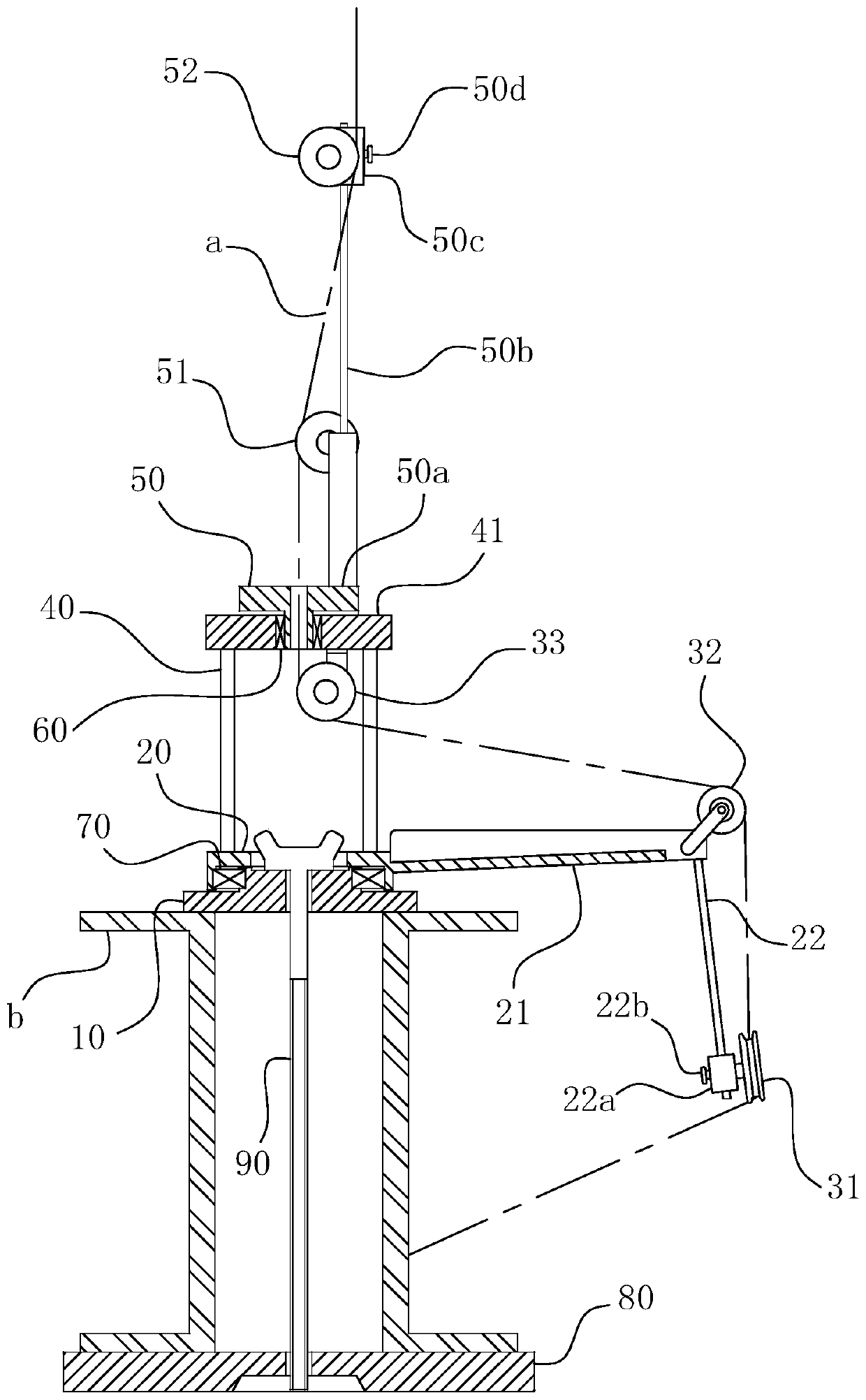

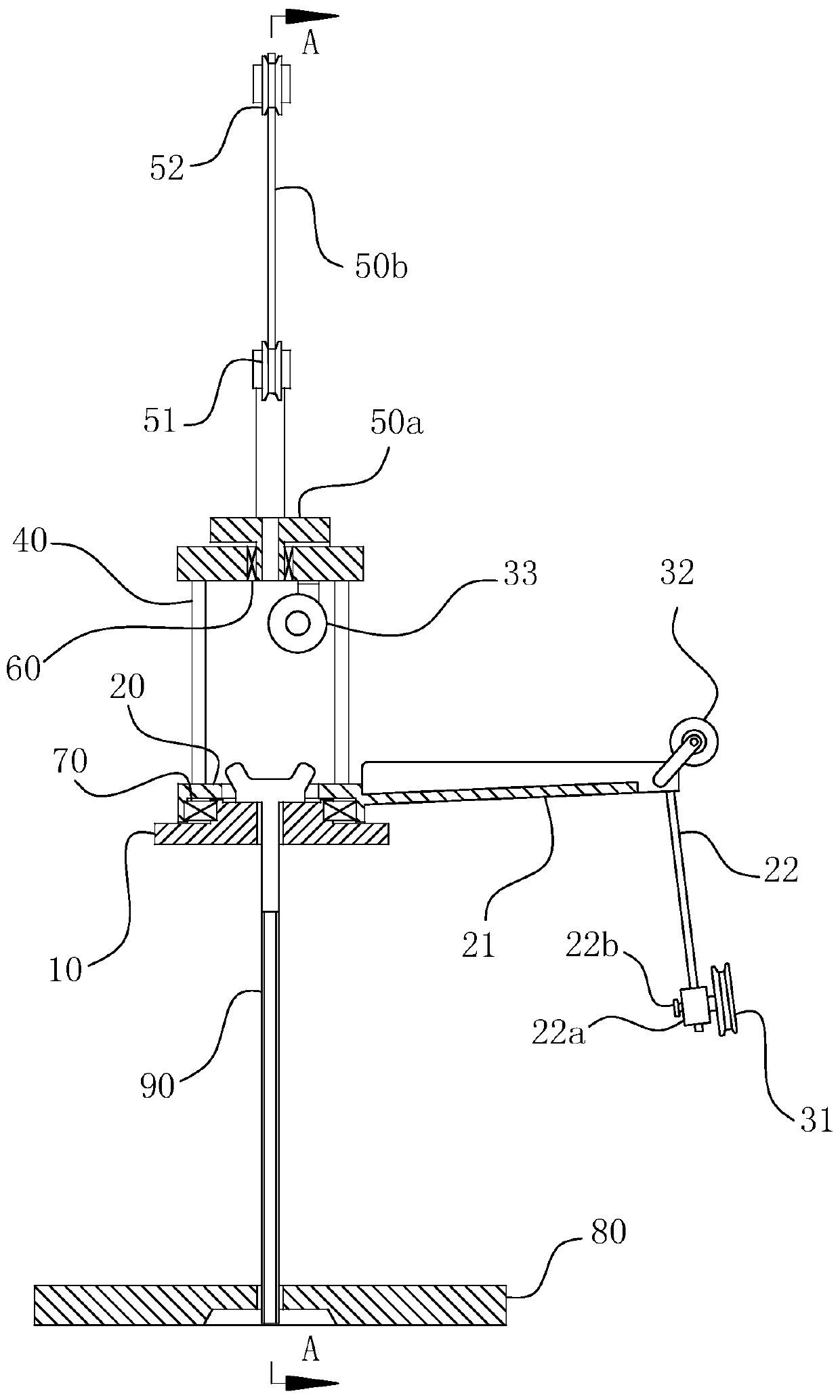

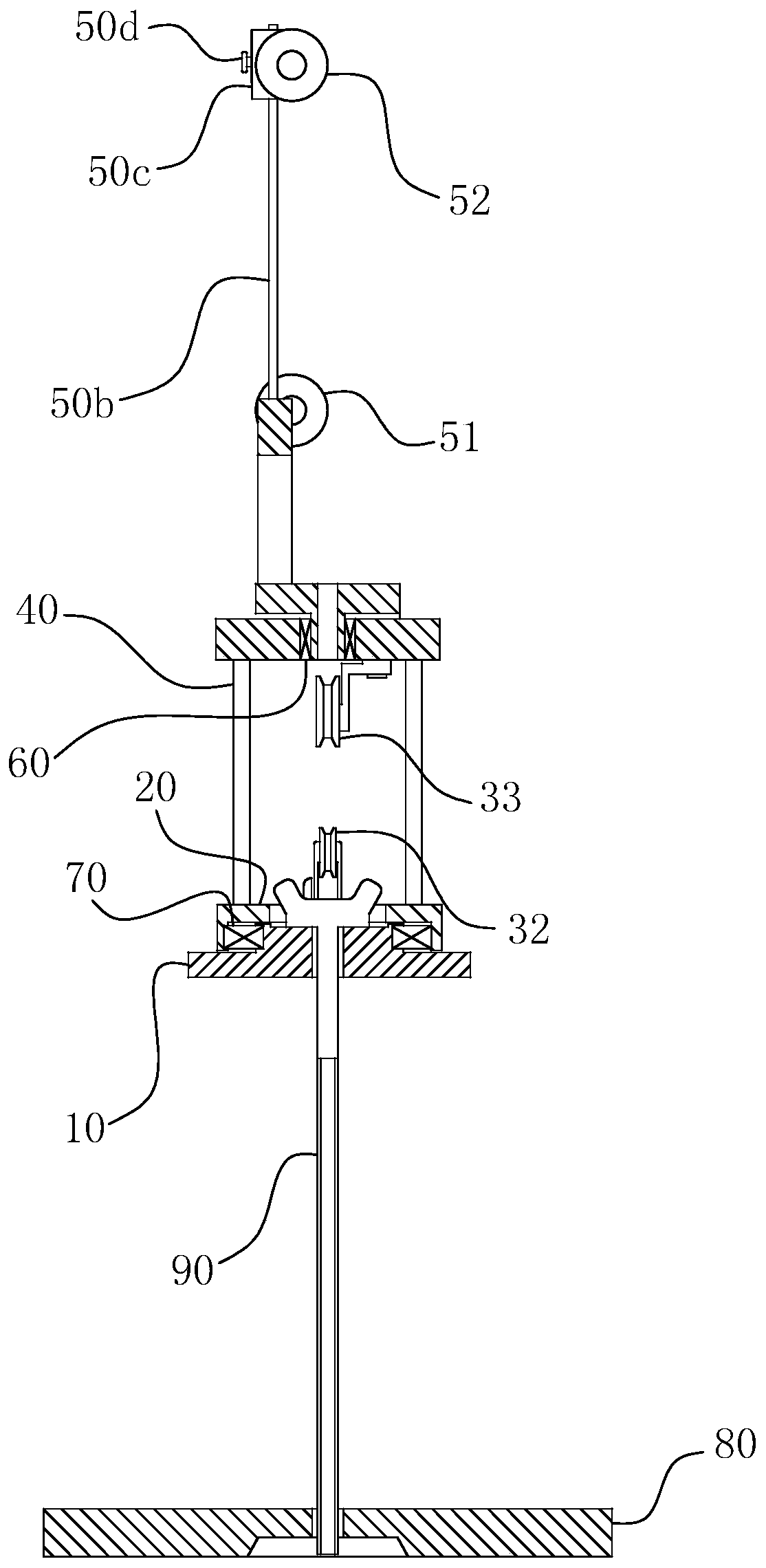

[0029] For ease of understanding, combined here Figure 1-3 Concrete structure of the present invention and working method thereof are described as follows:

[0030] The actual structure of the present invention can refer to Figure 1-3 As shown, it includes three major parts: the clamping and fixing assembly, the rotary drawing line assembly and the rotary force unloading assembly arranged sequentially from bottom to top. figure 1 The direction of the travel path of copper wire a and the function of in-line stress relief are shown. figure 1 In , the copper wire a is represented by a single dotted line to show the difference.

[0031] Clamping and fixing components such as Figure 2-3 As shown, it includes a bottom plate 80 , a top plate 10 and fixing screws 90 . The bottom plate 80 and the top plate 10 are parallel to each other, and they respectively face against the two ends of the coil b for winding the masterbatch. through as Figure 2-3 The passage of the fixing sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com