Modified guar gum thickener for papermaking paints and preparation method thereof

A technology of guar gum and thickener, applied in paper coating, papermaking, textiles and papermaking, etc., can solve the problems of poor resistance to dielectric microbial degradation, inability to rapidly swell and hydrate, and high content of water-insoluble matter, and achieve low cost, Solve the effect of flocculation and growth of microorganisms and reduce heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

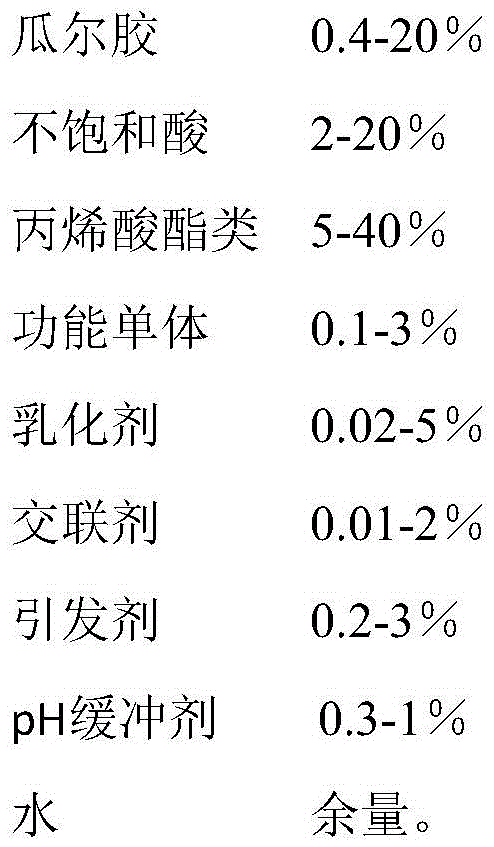

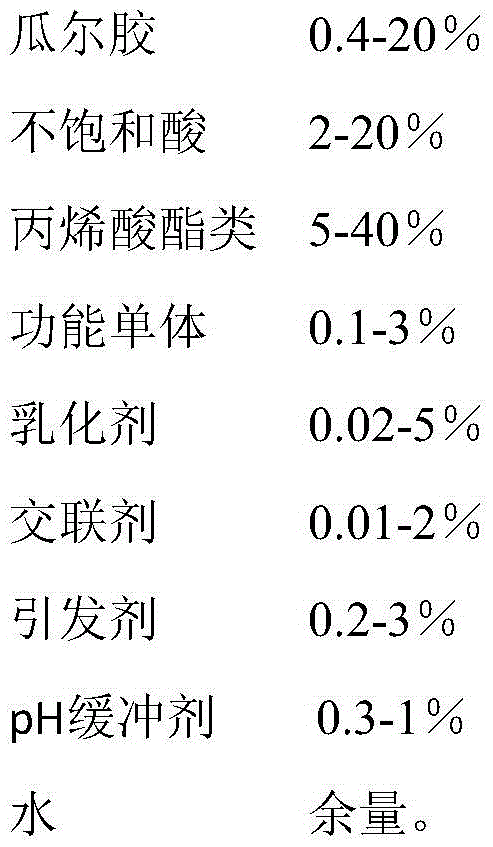

Method used

Image

Examples

example 1

[0025] Weigh 20g of deionized water, 10g of acrylic acid, 17g of butyl acrylate, 1g of fatty alcohol polyoxyethylene ether methacrylate, 3g of sodium lauryl sulfate, and 0.3g of DAP, mix evenly, heat slightly to dissolve, stir vigorously for 10 minutes and set aside. Weigh 0.4 g of potassium persulfate and dissolve it in 56 g of deionized water for later use.

[0026] Add 100g of deionized water, 20g of guar collagen powder, and 1g of potassium persulfate into a four-neck flask with a stirring and condensing device, start to heat up to 75°C, and after 3 hours of heat preservation, add 1g of acetic acid to the flask to adjust the pH value for 3-4.

[0027] Add the monomer mixture and potassium persulfate solution dropwise at the same time, and the dropwise addition is completed in 4 hours. After 3 hours of heat preservation, the temperature is lowered to below 30°C, and the milky white translucent liquid is discharged with a solid content of 26%. The viscosity is determined by ...

example 2

[0029] Weigh 20g deionized water, 6g methacrylic acid, 21g isooctyl methacrylate, 2g fatty alcohol polyoxyethylene ether methacrylate, 4g tristyrene polyoxyethylene methacrylate, 3g lauryl sulfate Sodium, 0.2g N,N-methylenebisacrylamide were mixed evenly, slightly heated to dissolve, stirred vigorously for 10min and set aside. Weigh 0.6 g of potassium persulfate and dissolve in 56 g of deionized water for later use.

[0030] Add 100g of deionized water, 20g of guar collagen powder, and 1g of potassium persulfate into a four-neck flask equipped with a stirring and condensing device, start to heat up to 65°C, and keep warm for 0.5h, then add 2g of acetic acid to the flask to adjust the pH The value is 3-4.

[0031] Add the monomer mixture and potassium persulfate solution dropwise at the same time, and the dropwise addition is completed in 3 hours. After 3 hours of heat preservation, the temperature is lowered to below 30°C, and the milky white translucent liquid is discharged,...

example 3

[0033] Weigh 20g deionized water, 13g acrylic acid, 14g ethyl methacrylate, 0.5g fatty alcohol polyoxyethylene ether methacrylate, 2g tristyrene polyoxyethylene methacrylate, 3g sodium lauryl sulfate, Mix 1g of OP-10 and 0.5g of N-methylolacrylamide evenly, heat slightly to dissolve, stir vigorously for 10min and set aside. Weigh 0.6 g of potassium persulfate and dissolve in 56 g of deionized water for later use.

[0034] Add 100g of deionized water, 30g of guar collagen powder, and 1g of potassium persulfate into a four-necked flask with a stirring and condensing device, start to heat up to 80°C, and after keeping the temperature for 0.5h, add 2.5g of acetic acid to the flask to adjust The pH value is 3-4.

[0035] Add the monomer mixture and potassium persulfate solution dropwise at the same time, and the dropwise addition is completed in 3 hours. After 3 hours of heat preservation, the temperature is lowered, and the discharge is milky white transparent liquid with a solid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com