Ultrasonic piezoelectric pump

a piezoelectric pump and ultrasonic technology, applied in the direction of pump components, positive displacement liquid engines, pump parts, etc., can solve the problems of affecting the efficiency of pumping, the cooling of electronic parts is becoming critical, and the conventional piezoelectric pump is not suitable for minimizing electronic products and medical equipment, so as to achieve smooth pumping and easy discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

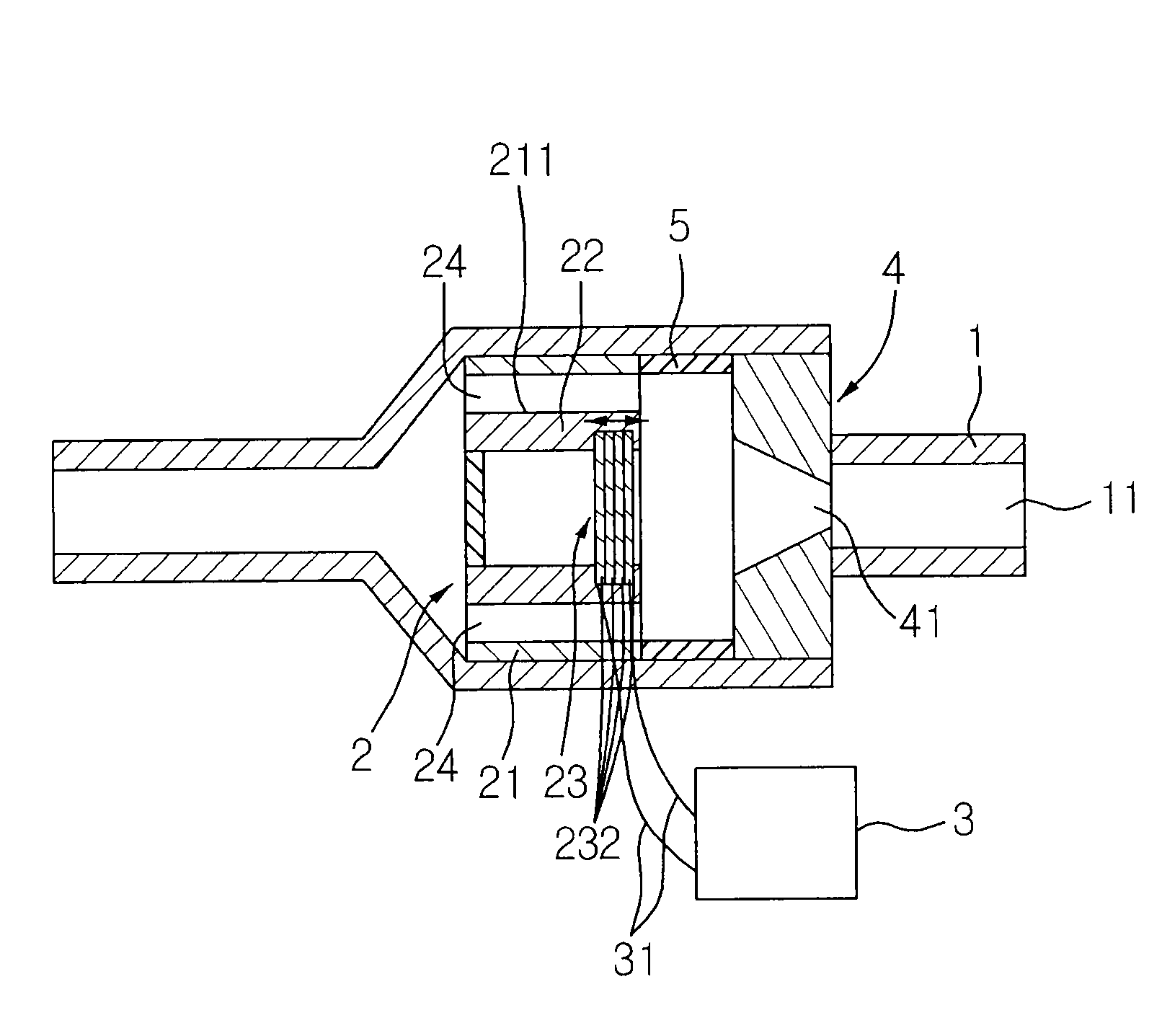

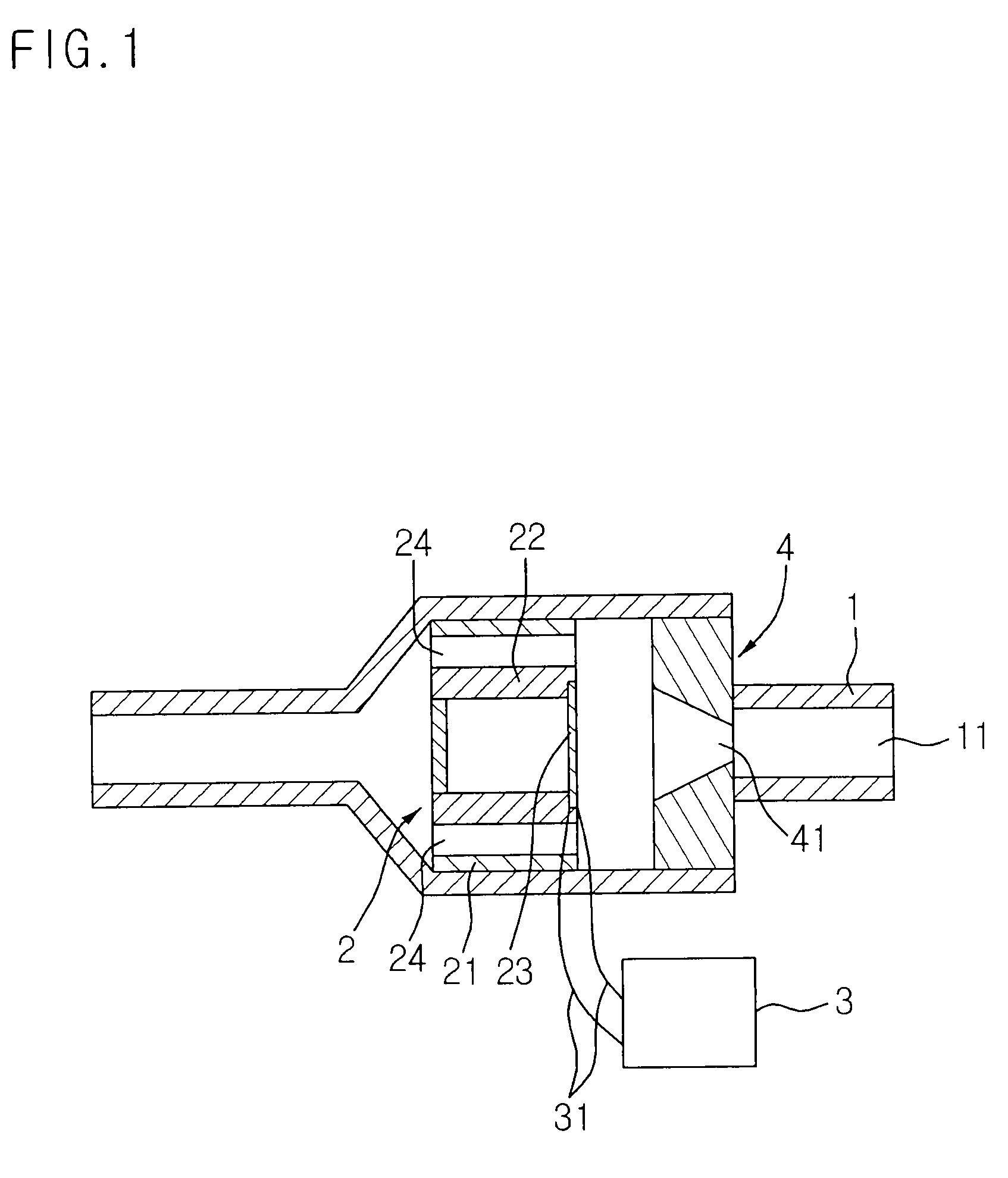

[0034]FIG. 1 is a sectional view illustrating an ultrasonic piezoelectric pump according to the present invention. The ultrasonic piezoelectric pump includes a fluid pipe 1, a piezoelectric pump 2, a controller 3, and a tapered nozzle 4.

[0035]The fluid pipe 1 has a hollow part 11 formed therein through which a fluid flows from a fluid source.

[0036]Moreover, the piezoelectric actuator 2 is inserted into the hollow part 11 and includes a piezoelectric device 23 and a plurality of fluid holes 24.

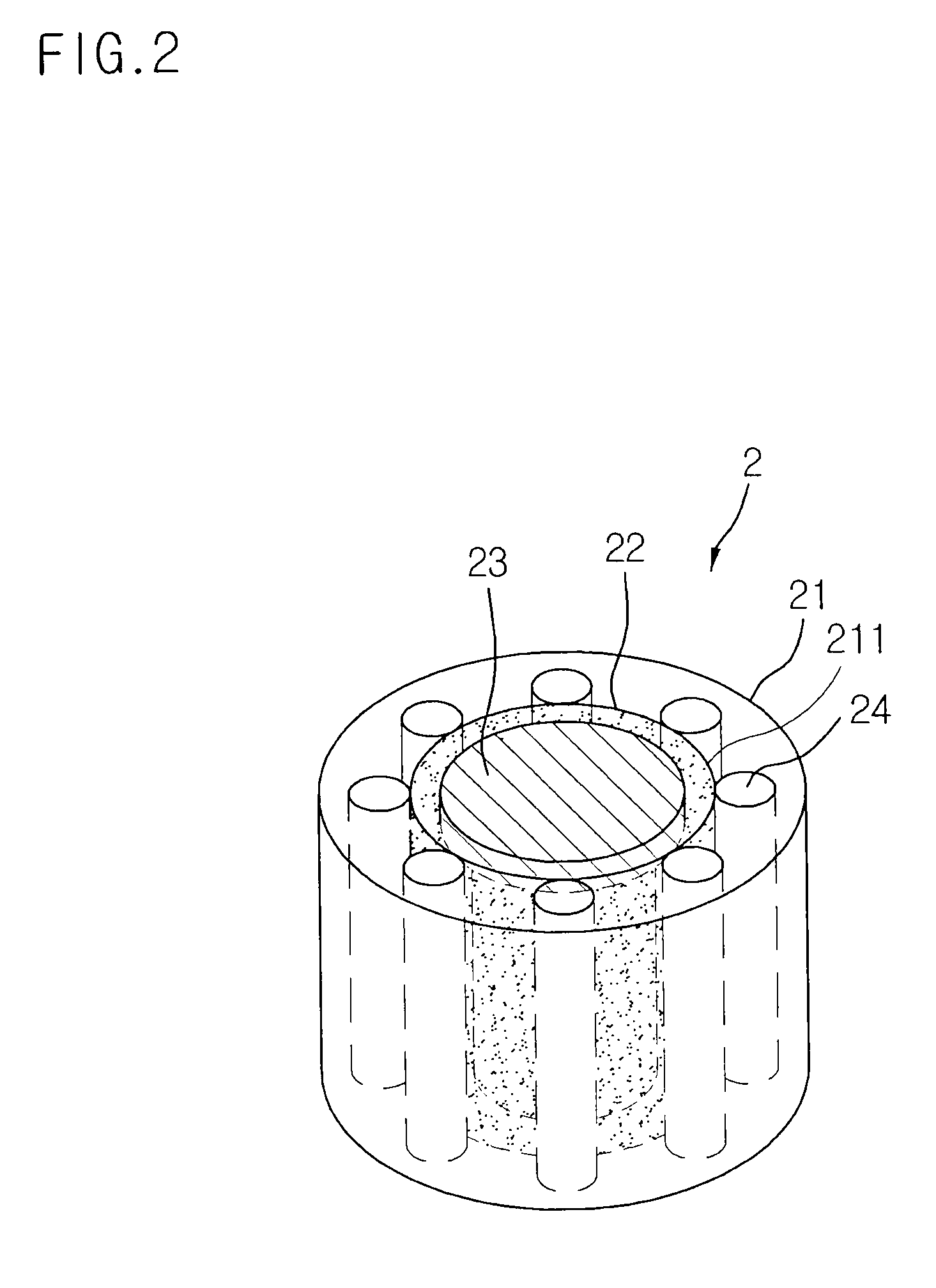

[0037]FIG. 2 is a perspective view illustrating the piezoelectric actuator of FIG. 1. The actuator 2 includes a case 21 with through-holes 211 formed at the center thereof, a frame 22, inserted into the through-holes 211, in which the piezoelectric device 23 is installed to the front side of the frame 22, and the plurality of fluid holes 24 formed in the vicinity of the frame 22 to penetrate the front side to the rear side of the case 21 and to permit the fluid supplied to the fluid pipe 1 to f...

second embodiment

[0041]FIG. 5 is a sectional view illustrating an ultrasonic piezoelectric pump according to the present invention. Hereinafter, structures and operations of the same components as those of FIG. 1 will be omitted.

[0042]Referring to FIG. 5, a distance adjusting circular ring 5 is provided in the hollow part 11 of the fluid pipe 1 between the piezoelectric actuator 2 and the tapered nozzle 4 to adjust a distance from the piezoelectric actuator 2 and the tapered nozzle 4.

[0043]In this case, the distance between the piezoelectric actuator 2 and the tapered nozzle 4 is preferably adjusted by the distance adjusting circular ring 5 to optimize the transmission of kinetic energy of the fluid.

[0044]FIG. 6 is a sectional view illustrating an ultrasonic piezoelectric pump according to a third embodiment of the present invention, and structures and operations of the same components as those of the first and second embodiments of the present invention will be omitted.

[0045]According to this embod...

fourth embodiment

[0060]FIG. 10 is a sectional view illustrating an ultrasonic piezoelectric pump according to the present invention. The ultrasonic piezoelectric pump includes a piezoelectric pump 1, a piezoelectric actuator 2, a controller 3, and a tapered nozzle 4.

[0061]The fluid pump 1 has a hollow part 11 formed therein through which a fluid flows from a fluid source.

[0062]Moreover, the piezoelectric actuator 2 is inserted into and fixed in the hollow part 11, and has a piezoelectric device 23 and a plurality of fluid holes 24.

[0063]Here, the actuator 2 includes a case 21 having a through-hole 211 formed at the center, a frame 22, inserted into the through-hole 211, to which the piezoelectric device 23 is installed, and a plurality of fluid holes 24 formed in the vicinity of the frame 22 to penetrate the front side to the rear side of the case 21 and to permit the fluid supplied to the fluid pipe 1 to flow therethrough.

[0064]The piezoelectric device 23 may include a multi-layer piezoelectric dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com