Self-propelled proportioning, stirring and pumping vehicle

A stirring pump and self-propelled technology, which is applied to cement stirring devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of low production efficiency, time-consuming installation and debugging, large floor space, etc., and achieve high production efficiency. , Small footprint and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

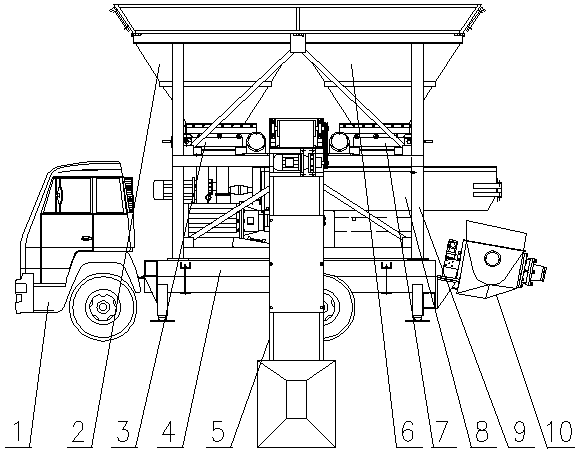

[0007] attached figure 1 As shown, the present invention installs a complete machine support 9 on the chassis of the truck 1, and the complete machine support 9 is integrated with a gravel bin 2, a sand bin 6, a cement feeding device 5 and a concrete pumping device. The chassis of the truck 1 is provided with a hydraulic support device to ensure the stability of the equipment during operation.

[0008] The gravel bin 2 and the sand bin 6 are placed side by side on the top of the whole machine support 9, respectively connected to the feed port of the mixer through the gravel belt 3 and the sand belt 7, and a bidirectional screw device is installed in the feed port of the mixer to ensure uniform feeding. The sand bin 6 top is provided with a sand screening device to remove sundries.

[0009] Before the mixing operation starts, the cement feeding device 5 is placed in a suitable position after other equipment is in place. The cement hopper of the cement feeding device 5 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com