Special concrete pumping agent for ultra-high buildings and preparation method thereof

A concrete and super high-rise technology, applied in the field of building materials, can solve problems such as concrete bleeding, concrete segregation, and pump blockage, and achieve the effects of avoiding water, reducing initial viscosity, and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

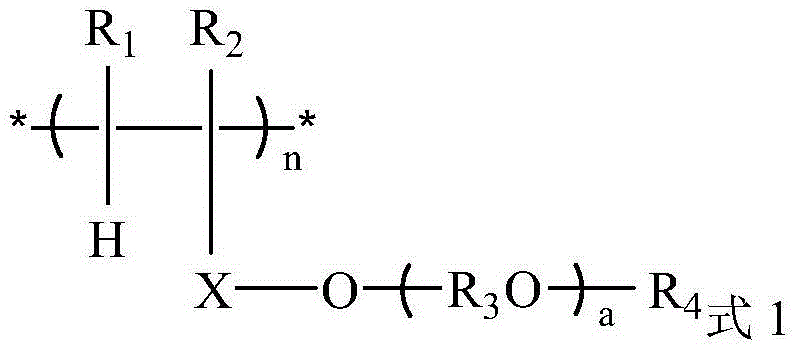

Method used

Image

Examples

Embodiment 1

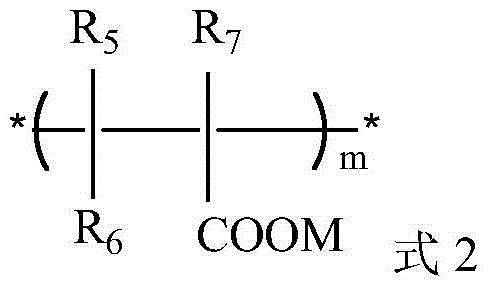

[0028] A special pumping agent for super high-rise building concrete, which is prepared from the following raw materials in solvent water, and the dosage of each raw material is as follows:

[0029]

[0030]

[0031] The preparation method of the above-mentioned special pumping agent for super high-rise building concrete comprises the following steps:

[0032] 1) With the above proportioning ratio, take each raw material for subsequent use;

[0033] 2) Carboxylic acid A, methyl acrylate and mercaptoethanol are dissolved in 80g water to form aqueous solution A, and ammonium persulfate is dissolved in 80g water to form aqueous solution B;

[0034] 3) Under the protection of nitrogen, in a 500ml four-neck flask equipped with a thermometer, a stirrer and a dropping funnel, add 100g of deionized water, polyether A and starch acrylate in sequence, heat and stir in a water bath, and control the temperature at about 40°C ; After the polyether A and starch acrylate are fully dis...

Embodiment 2

[0038] A special pumping agent for super high-rise building concrete, which is prepared from the following raw materials in solvent water, and the dosage of each raw material is as follows:

[0039]

[0040] The preparation method of the above-mentioned special pumping agent for super high-rise building concrete comprises the following steps:

[0041] 1) With the above proportioning ratio, take each raw material for subsequent use;

[0042] 2) Sodium carboxylate B, ethyl acrylate, and 2-hydroxypropanethiol were dissolved in 80g water to form aqueous solution A, and ammonium persulfate was dissolved in 80g water to form aqueous solution B;

[0043] 3) Under the protection of nitrogen, in a 500ml four-neck flask equipped with a thermometer, agitator and dropping funnel, add 100g of deionized water, polyether B and starch acrylate in sequence, heat and stir in a water bath, and control the temperature at about 40°C ; After the polyether B and starch acrylate are fully dissolv...

Embodiment 3

[0045] A special pumping agent for super high-rise building concrete, which is prepared from the following raw materials in solvent water, and the dosage of each raw material is as follows:

[0046]

[0047]

[0048] The preparation method of the above-mentioned special pumping agent for super high-rise building concrete comprises the following steps:

[0049] 1) With the above proportioning ratio, take each raw material for subsequent use;

[0050] 2) Calcium carboxylate C, isobutyl acrylate and mercaptoacetic acid were dissolved in 80g water to form aqueous solution A; the potassium persulfate was dissolved in 80g water to form aqueous solution B;

[0051] 3) Under the protection of nitrogen, in a 500ml four-necked flask equipped with a thermometer, a stirrer and a dropping funnel, add 100g of deionized water, polyether C and acrylamide monomer in sequence, heat and stir in a water bath, and control the temperature at 40°C About; After the polyether C and acrylamide mon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com