Intermediate shaft structure of gearbox

A technology of gearbox and intermediate shaft, applied in the field of gearbox, can solve the problem of low NHV index, and achieve the effect of improving accuracy, shortening axial size and reducing axial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

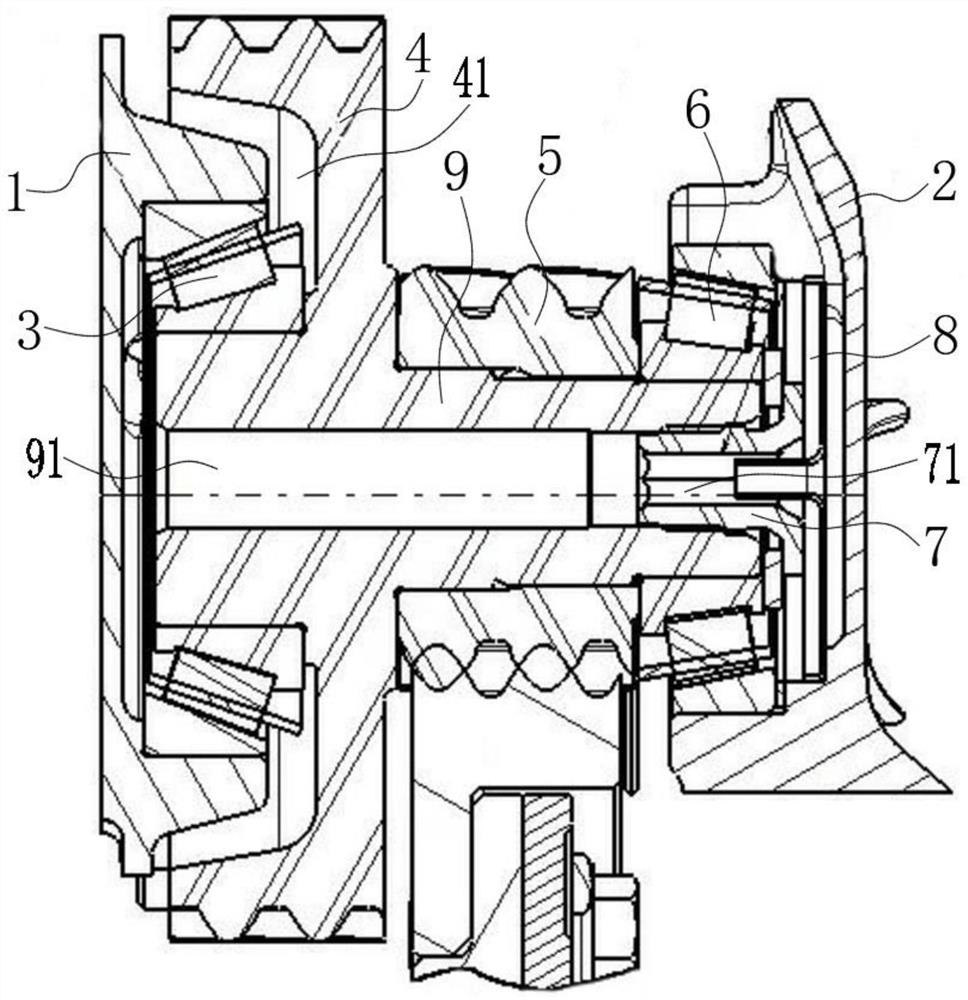

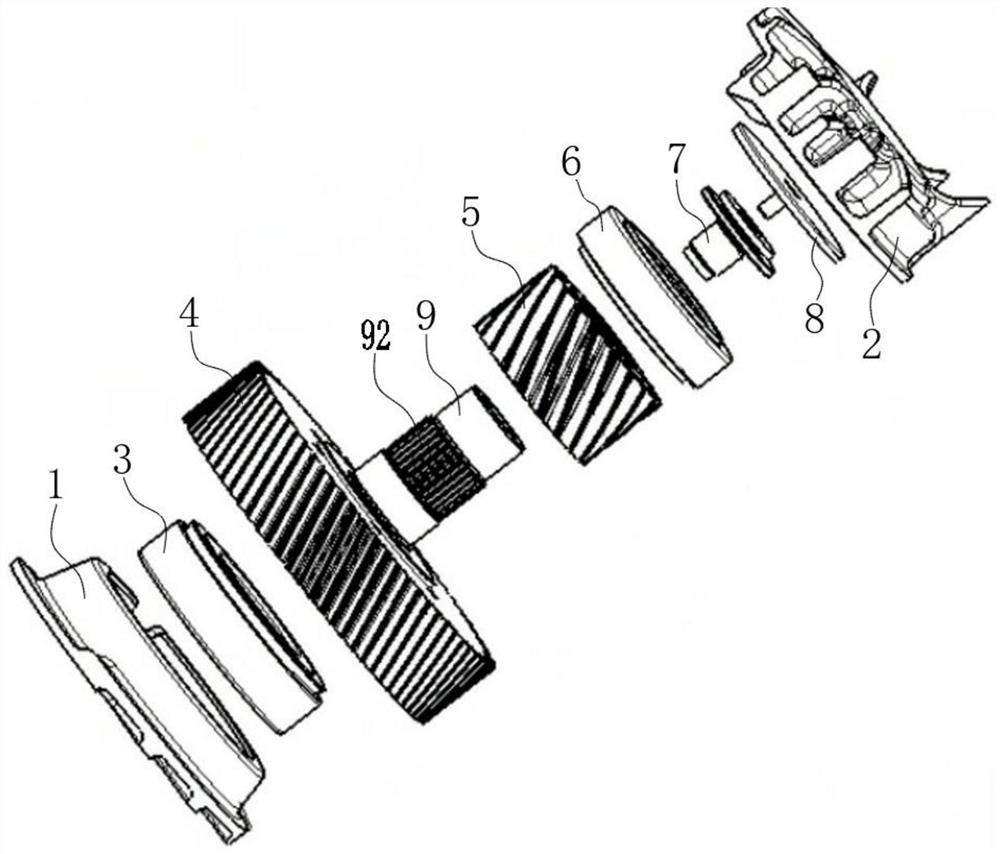

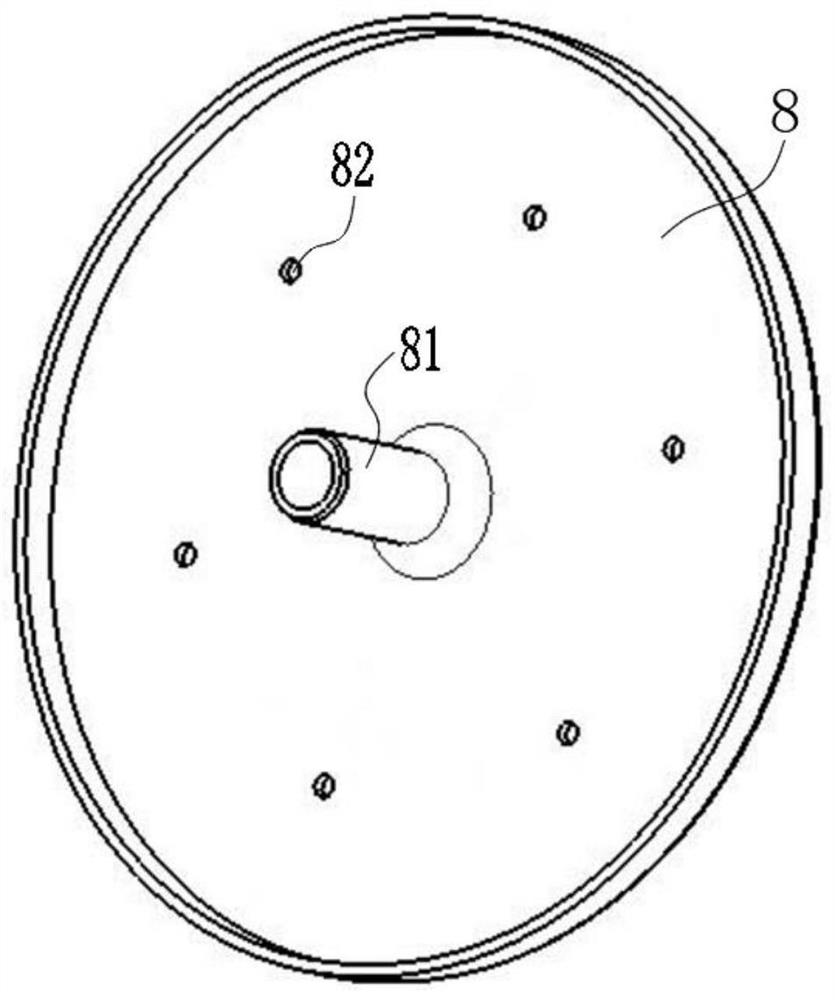

[0032] The invention provides a gearbox intermediate shaft structure, such as Figure 1 to Figure 3 As shown, it includes a gearbox housing, a first bearing 3 , a first gear 4 , a second gear 5 , a second bearing 6 , a nut 7 , an oil guide 8 and a shaft body 9 . The shaft body 9 is provided with an axially penetrating cavity 91 for guiding the flow of lubricating oil. The first gear 4 and the second gear 5 are arranged on the outer wall of the shaft body 9 , and the first gear 4 and the shaft body 9 are integrally formed. External splines are provided on the outer wall of the shaft body 9 , internal splines are provided on the second gear 5 , and the second gear 5 slides along the splines 92 to approach the first gear 4 .

[0033] Such as Figure 1 to Figure 3 As shown, a first bearing 3 on one side of the first gear 4 is connected between the shaft body 9 and the gearbox housing, and the first bearing 3 can make the first gear 4 rotate relative to the gearbox housing. A se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com