Compact valve box device for rotating upper sealing valve of blast furnace

A sealing valve and sealing box technology, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as no application of sealing valves and valve boxes, difficulty in installing sealing valves, etc., and meet the requirements of reverse U-shaped stacking , Reduce labor intensity, easy to make effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

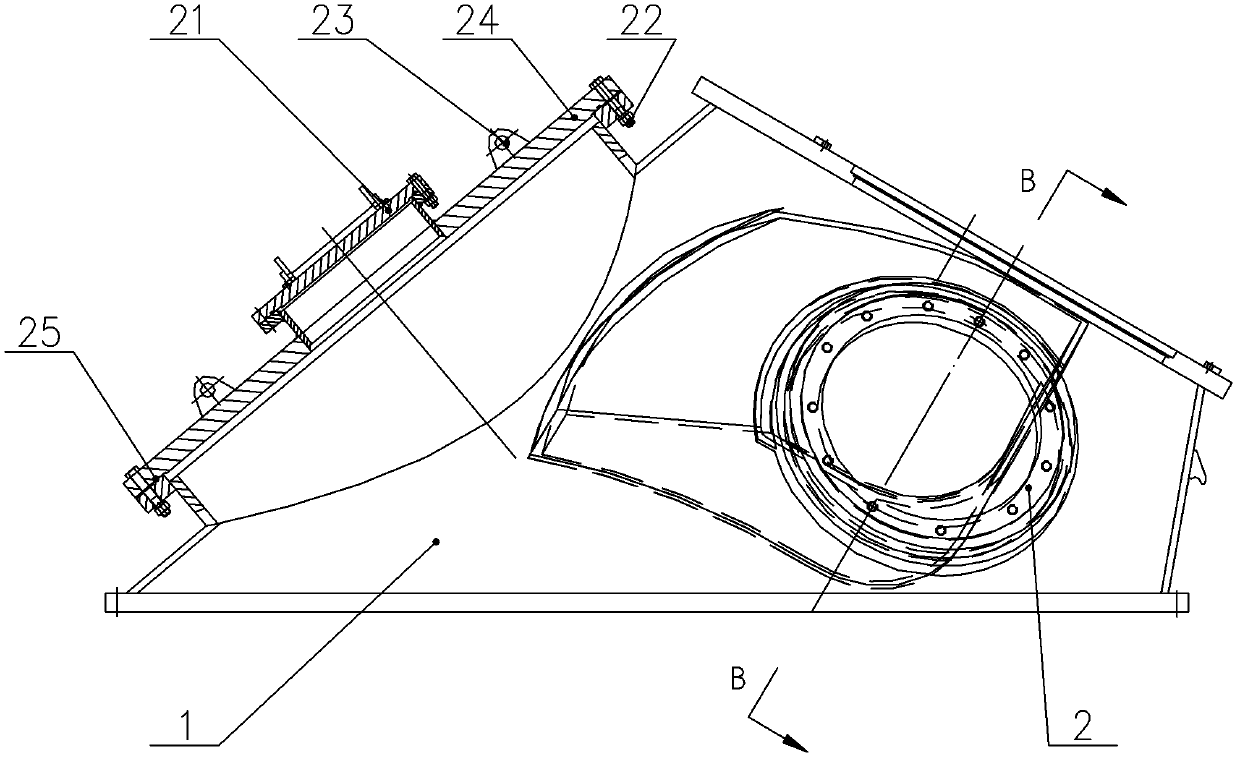

[0036] The following is attached Figure 1-8 The embodiment of the present invention is described further, but does not limit the present invention.

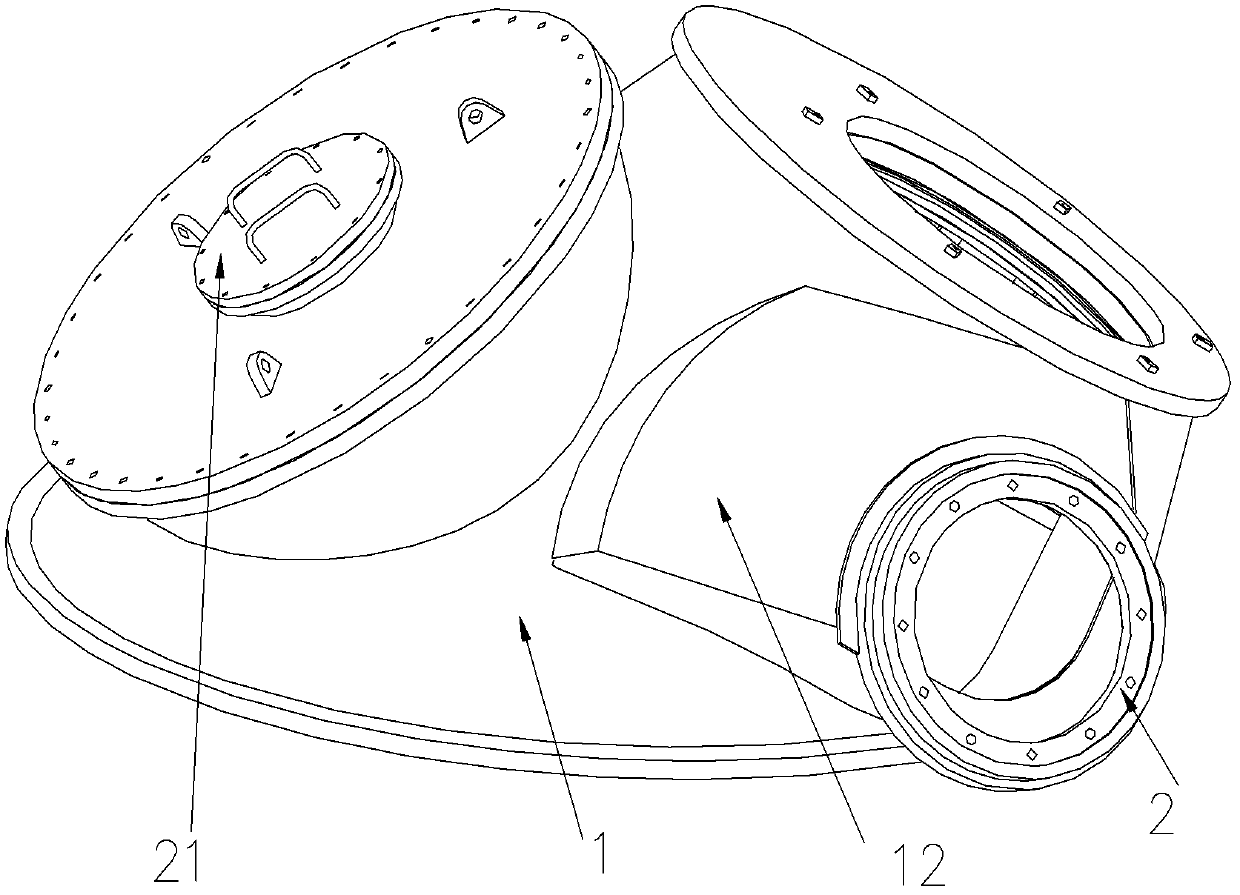

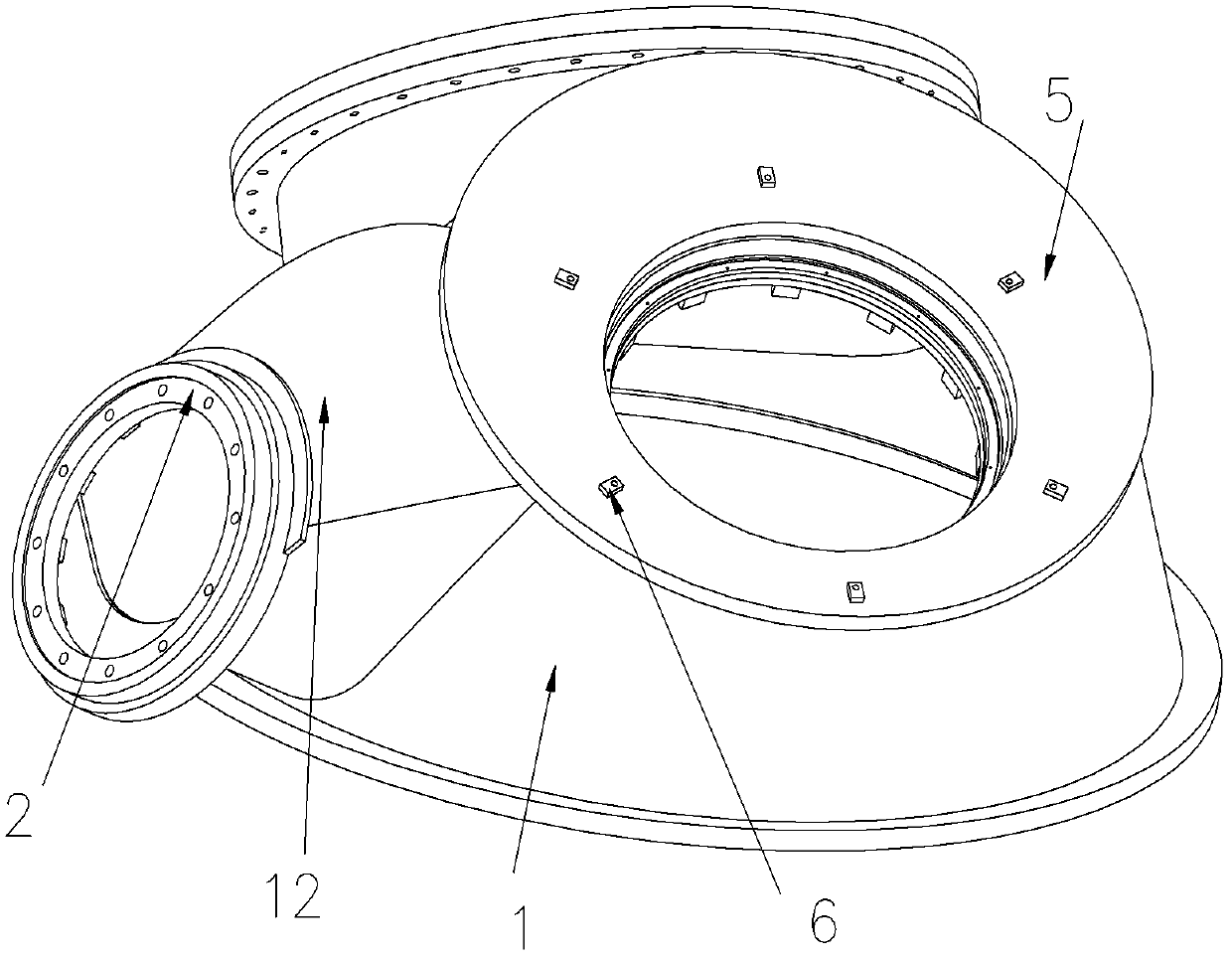

[0037] The valve box device is composed of two parts, one part is an open flange valve box connecting frame 2 connected with the rotary sealing valve, and the other part is a sealing box body 1 adapted to the working space of the rotating upper sealing valve. Such as figure 1 and 2 shown.

[0038] Seal box body 1 is mainly made up of manhole, seal box shell 8, feed inlet, as figure 1 and 2 shown.

[0039] The sealing box housing 8 adopts the shape of a positive conical frustum, such as Figure 5 and 6 As shown, the top is small and the bottom is large, and the central axis is inclined at an angle of 60 degrees to the horizontal direction. The bottom horizontally arranged material tank connecting flange 10 is along the bottom end of the busbar on the upper side of the positive conical frustum of the sealing box shell 8 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com