Creeper tread for track type moving implement

A crawler shoe and crawler type technology, which is applied to the crawler shoe field of crawler-type mobile implements, can solve the problems of increased labor cost, increased assembly cost, inconvenience, etc., and achieves the effect of quick and easy disassembly and assembly, convenient operation, and reduced manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

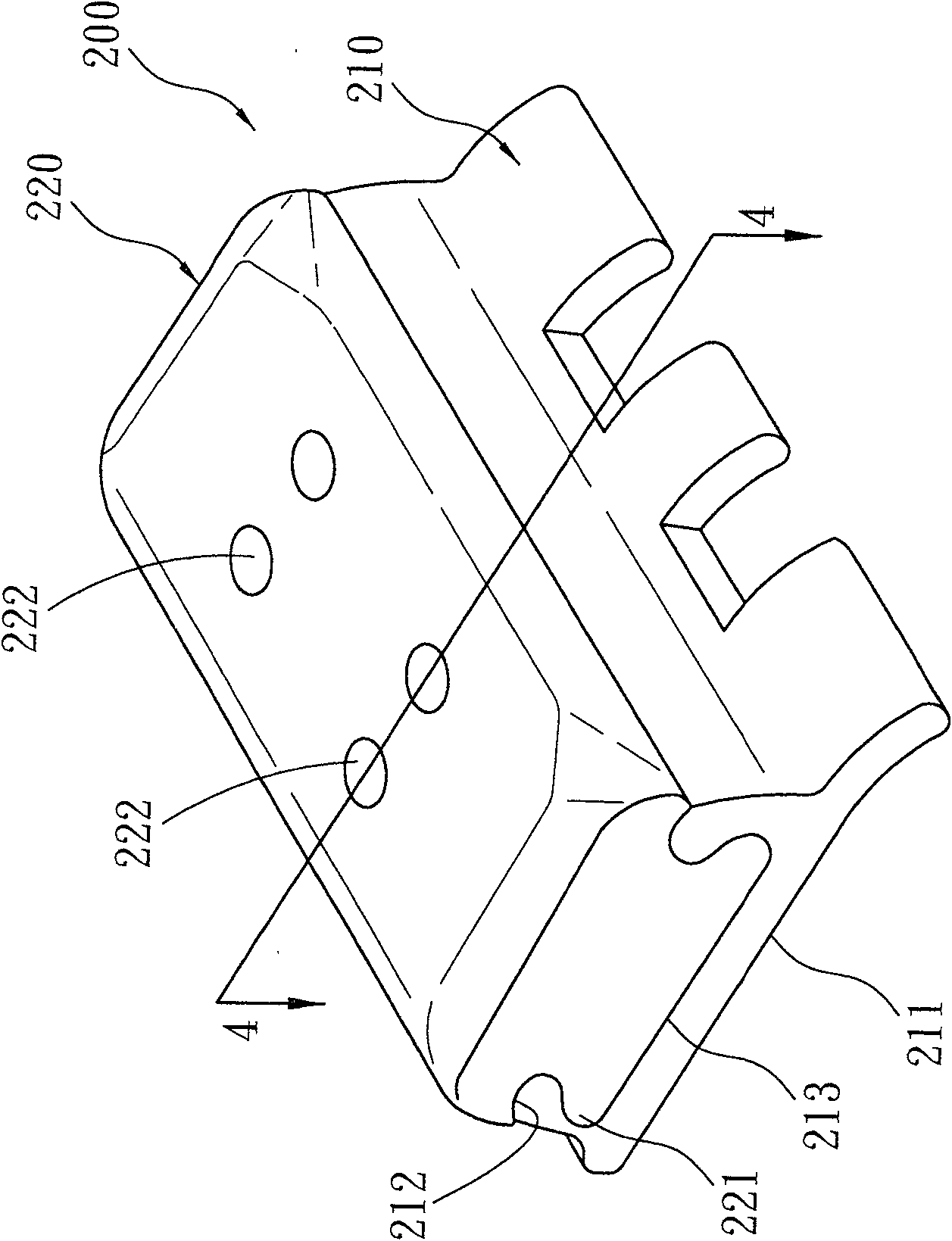

[0028] refer to image 3 and Figure 4 The track shoes 200 of the crawler-type mobile device shown are arranged in plural and locked on a chain (not shown) of the mobile device, and include a track shoe body 210 and a rubber block 220 .

[0029] The track shoe body 210 is a metal plate body, and the track shoe body 210 includes an upper surface 211 adjacent to the chain, a lower surface 212 opposite to the upper surface 211, and a recessed surface 212 on the lower surface 212. The embedding groove 213 and a plurality of through holes 214 .

[0030] Each of the perforations 214 passes through the upper surface 211 and the lower surface 212 of the track shoe body 210 respectively, and communicates with the embedding groove 213 .

[0031] The embedding groove 213 has an opening portion 2131 and a groove portion 2132 . The opening 2131 is smaller than the groove 2132. The peripheral cross section of the opening 2131 presents a convex bulging shape, while the peripheral wall cro...

no. 2 example

[0038] refer to Image 6 The track shoe of another crawler-type mobile device shown, the track shoe 200 includes a track shoe body 210 and a rubber block 220, and the track shoe body 210 and the rubber block 220 in this embodiment Figure 4 The structure of the track shoe body 210 in the first embodiment is the same, the difference is that the locking hole of the rubber block 220 is set as a blind hole 223 type, and a nut 224 is buried inside each blind hole 223 .

[0039] In this way, when the track shoe 200 is to be installed on the track shoe chain (chain), the locking element 300 from the track shoe chain (chain) is passed through the hole 214 of the track shoe body 210 and the rubber block 220 The blind hole 223 can be locked on the embedded nut 224.

[0040] To sum up the above, due to the track shoes of the crawler-type mobile equipment of the present invention, the rubber blocks 220 are combined on the track shoe body 210 by inserting cards, and there is no need to comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com