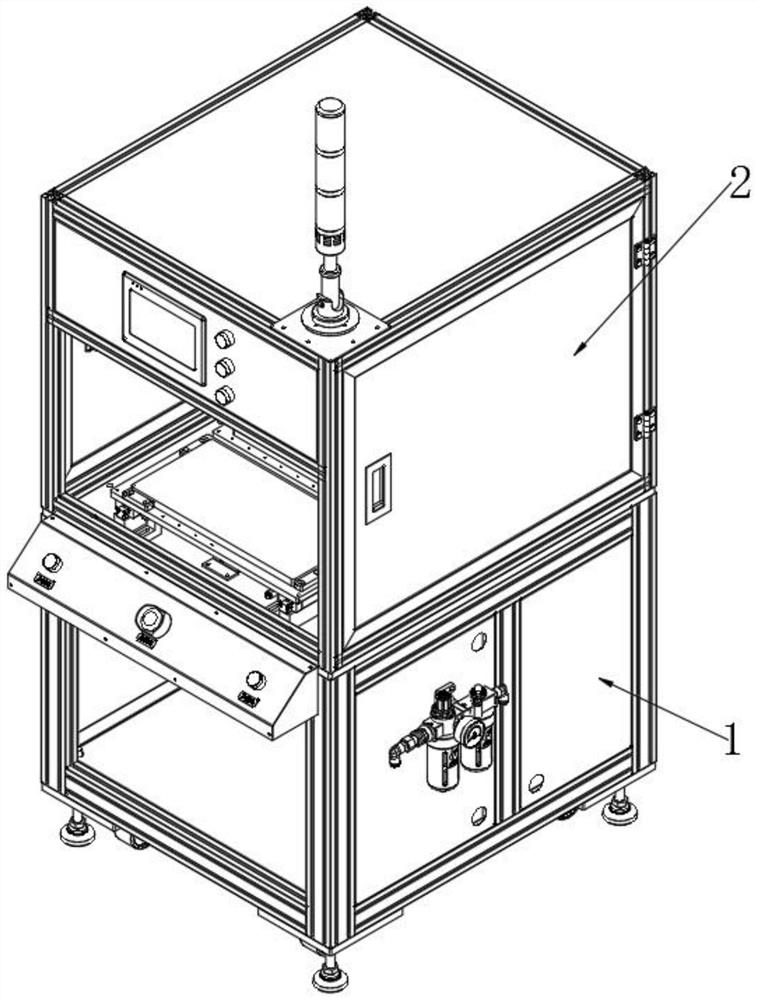

Thickness measuring device for lithium battery processing and working method thereof

A technology of thickness measurement and lithium battery, which is applied in the direction of measuring devices, instruments, etc., can solve the problems of deviation and inability to measure the thickness of lithium batteries separately, and achieve the effect of the same position and easy positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

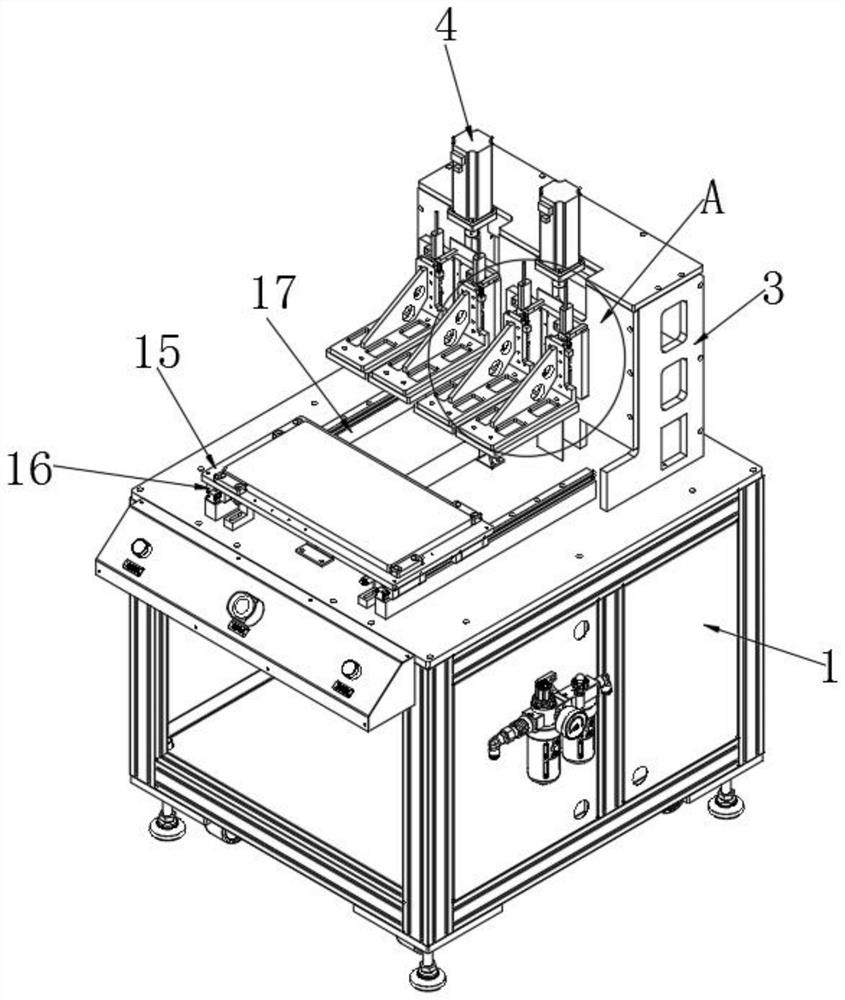

[0038] As an embodiment of the present invention, both sides of the top of the mounting plate 15 are provided with sliding seats 16, both sides of the top of the stand 1 are provided with second slide rails 17, and the slide seats 16 are slidably mounted on the second slide rails 17. The second threaded rod 13 and the second slider 14 are threadedly connected, and the second servo motor 12 works to drive the second threaded rod 13 to rotate. At this time, the second slider 14 drives the mounting plate 15 to translate along with the rotating second threaded rod 13 . Moreover, the slider 16 slides on the second sliding rail 17 to play the role of limiting and guiding.

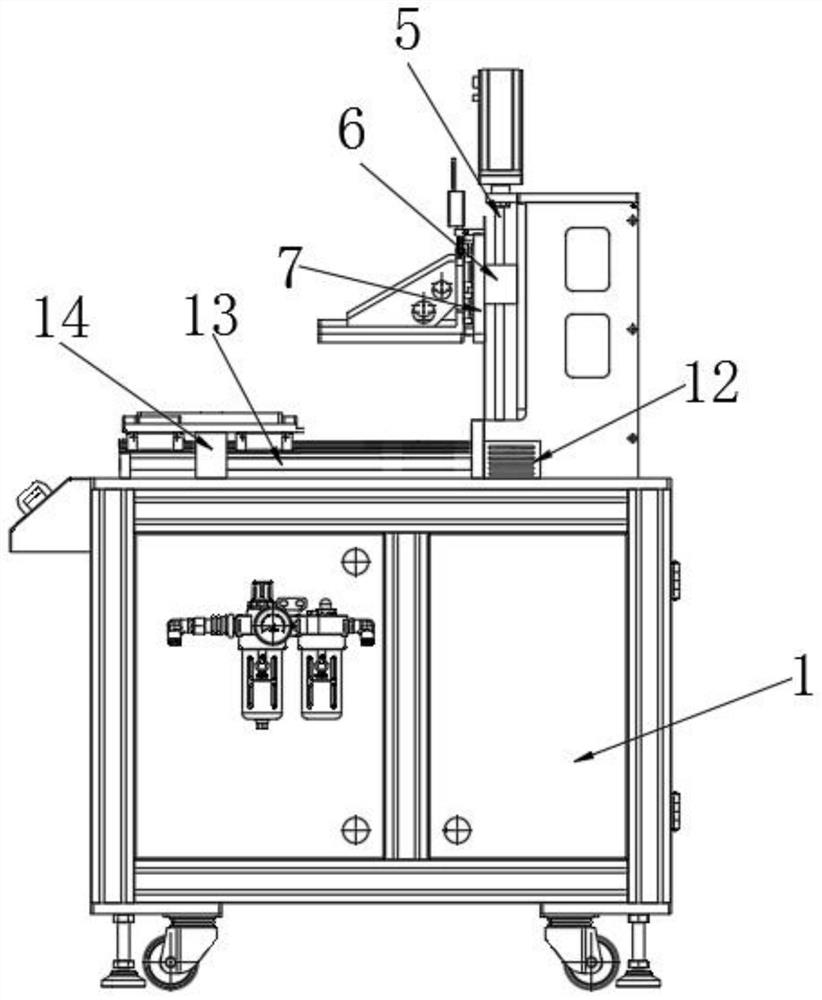

[0039]As an embodiment of the present invention, the third threaded rod 24 is threadedly connected with the threaded sleeve 25, the lifting seat 22 is matched with the lifting groove, and the third servo motor 23 works to drive the third threaded rod 24 to rotate. At this time, the threaded sleeve 25 Along with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com