Mechanical fault monitoring and diagnosis system establishment method based on SDAE-RCmvMSE

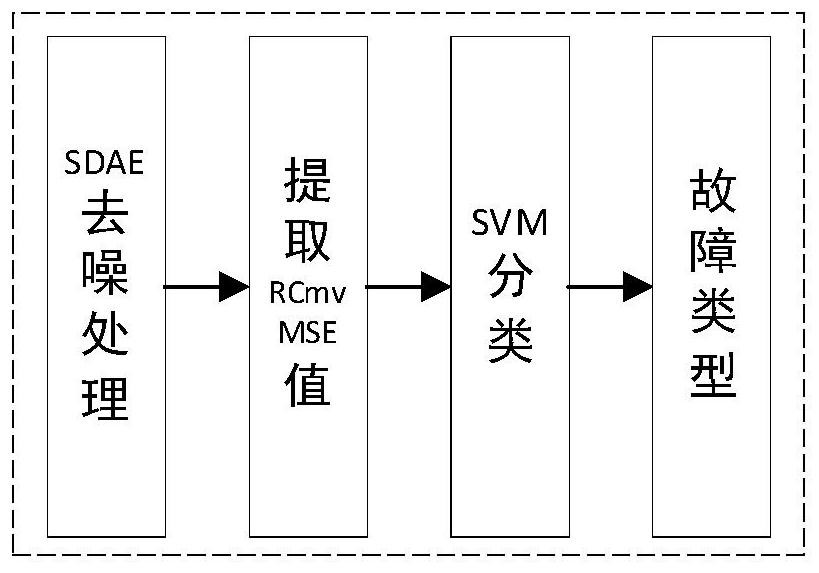

A diagnostic system and mechanical failure technology, which is applied in the establishment of SDAE-RCmvMSE-based mechanical failure monitoring and diagnosis system, can solve the problems of large signal noise, difficulty in extraction, poor stability of vibration signals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

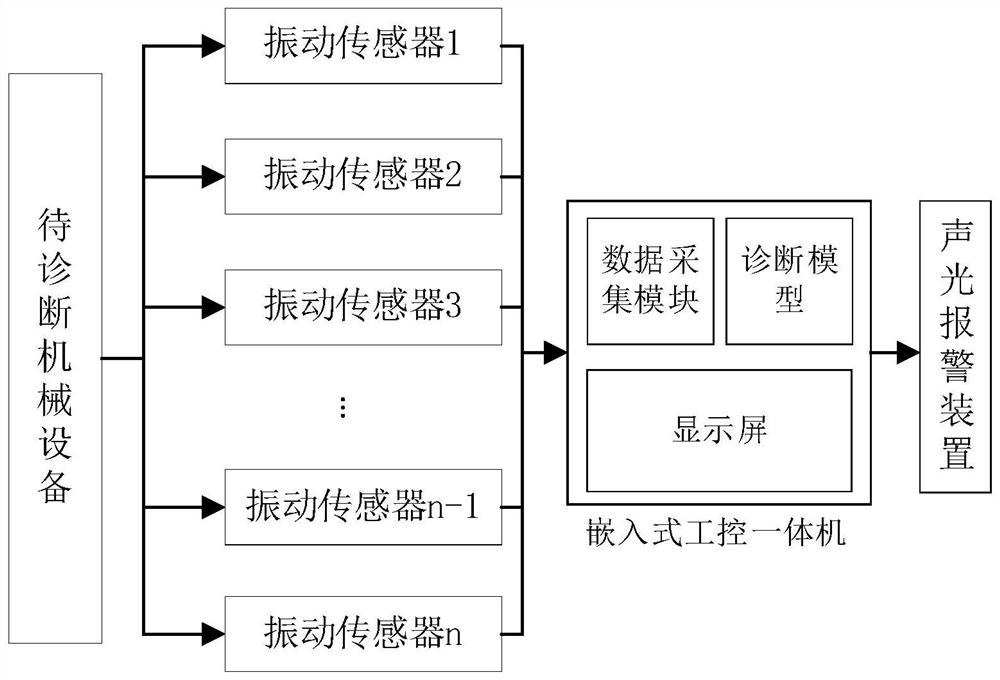

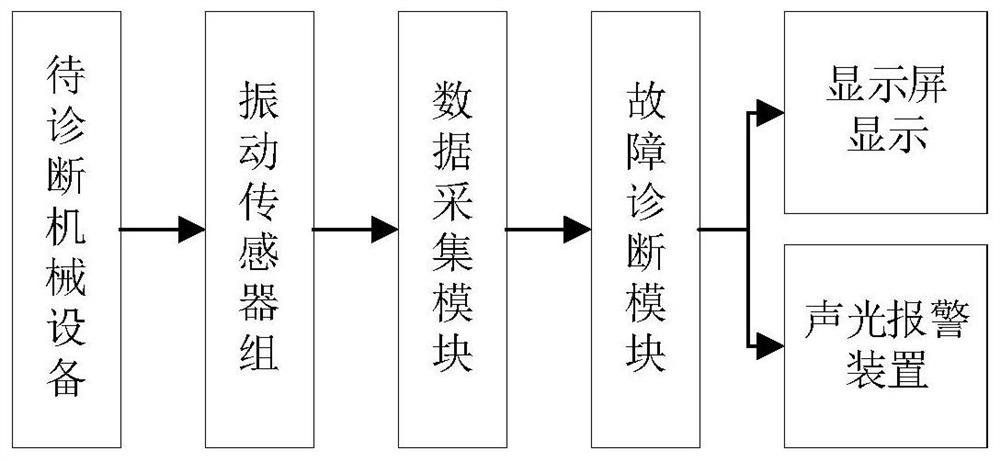

[0063] 1. System composition

[0064] This project uses a mechanical fault monitoring and diagnosis system based on SDAE-RCmvMSE, which includes an acceleration sensor unit, an embedded industrial control machine and an audible and visual alarm device. The embedded industrial control all-in-one machine is composed of industrial computer, data acquisition module, diagnostic model, display screen and other functional modules. The system composition is as follows: figure 1 shown.

[0066] Install the acceleration sensor in the appropriate position of the mechanical equipment to be monitored. After the system is started, the embedded industrial control all-in-one machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com