Device and method for simultaneous sampling and time-sharing wheel measurement of NOx of SCR denitration system

A denitrification and sampling tube technology, which is applied to the structural details of measuring devices, sampling devices, gas analyzers, etc., can solve the problems of high-efficiency, stable and economical operation of ultra-low emission, uneven distribution of flue concentration field, and inability to effectively reflect Gas composition distribution and other issues to achieve the effect of reducing impact, reducing costs, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

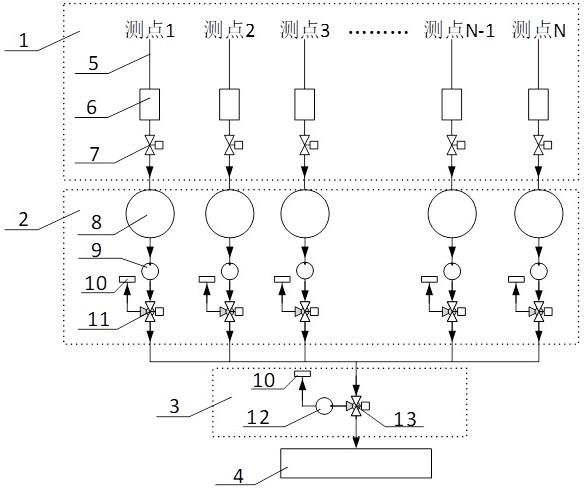

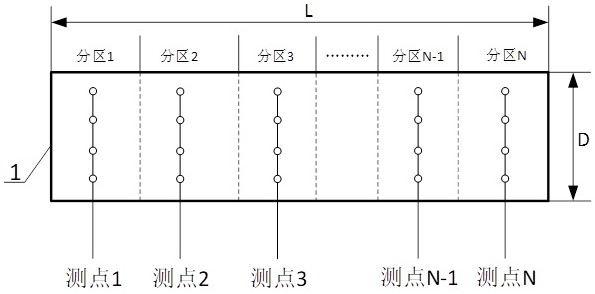

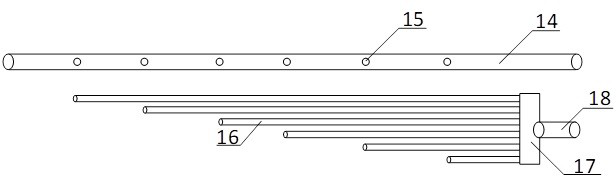

[0025] Such as figure 1 , a device for simultaneous sampling and time-sharing testing of NOx in an SCR denitrification system, comprising a simultaneous sampling system 1, a sample gas storage system 2, a time-sharing testing system 3 and a flue gas analyzer 4, a simultaneous sampling system 1, a sample gas storage system 2. The time-sharing wheel measurement system 3 and the flue gas analyzer 4 are connected in sequence, and the sampling system 1 simultaneously collects flue gas samples at multiple measuring points at the cross section of the flue through the sampling pipe 5, and then enters the sample gas storage system 2 for storage. Finally, enter the flue gas analyzer 4 for measurement and analysis through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com