battery module

A battery module and battery technology, which is applied in the direction of batteries, battery components, secondary batteries, etc., can solve the limitation of the internal space size of the battery module, the width and thickness of the connecting piece cannot be too large, and affect the battery module. Discharge power and other issues to achieve the effect of avoiding power limit in advance, optimizing structure and performance, and optimizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

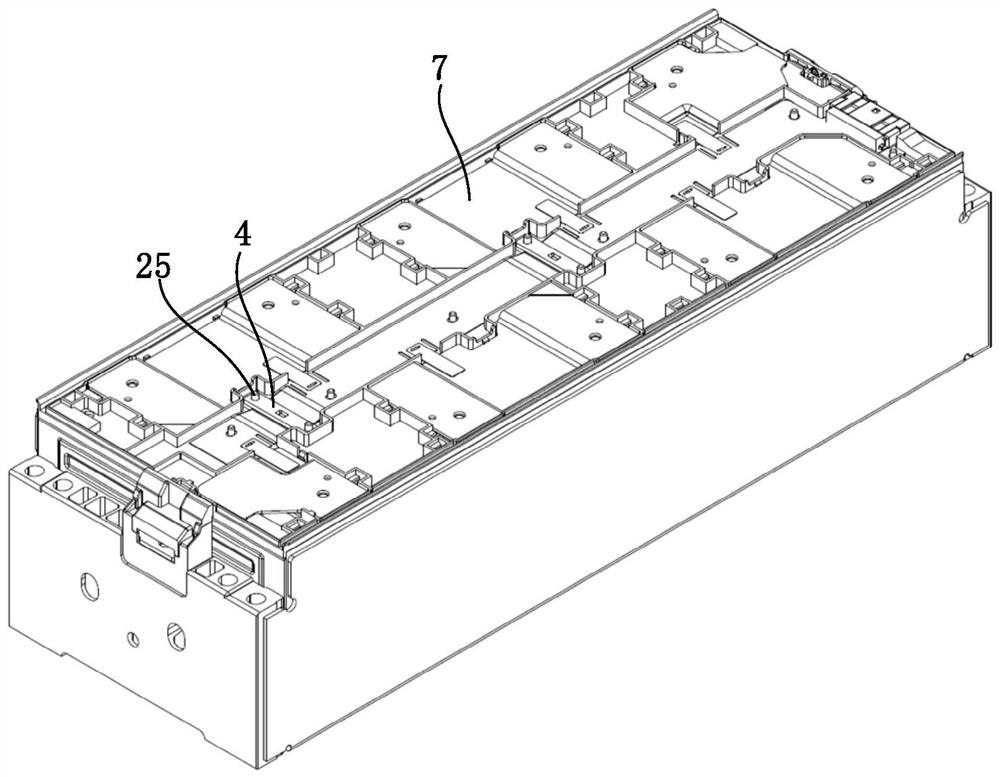

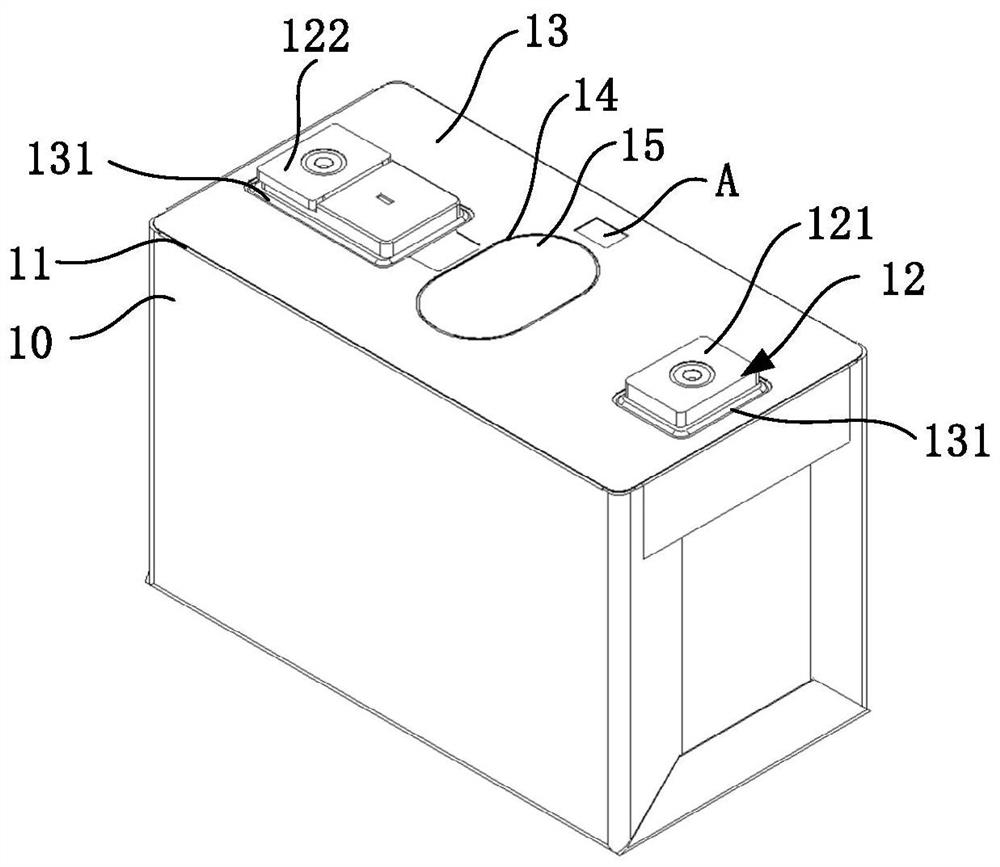

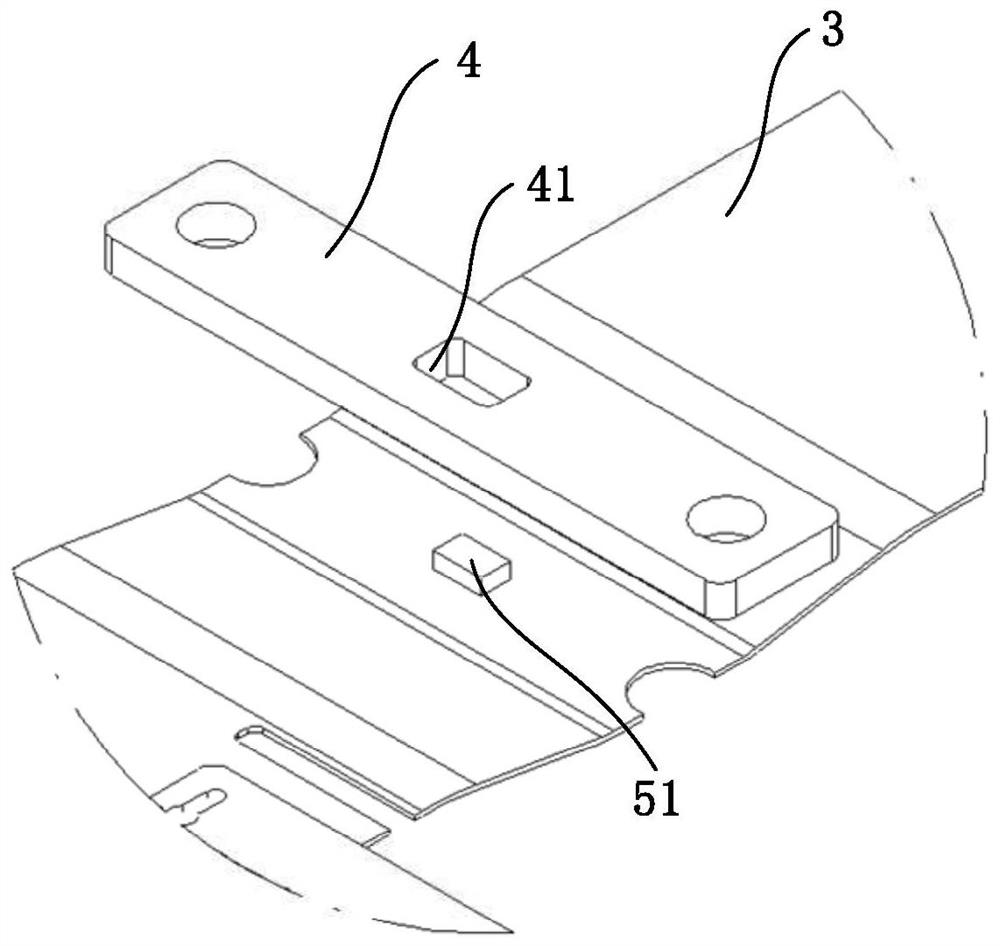

[0050] Combine below Figure 1 to Figure 14 The technical solution provided by the present invention is described in more detail.

[0051] see Figure 1 to Figure 14 , the embodiment of the present invention provides a battery module, including a battery 1 , a wiring harness board 2 , a circuit board 3 , a pressing member 4 and a temperature collection assembly 5 . The battery 1 includes a top cover 11 . The wiring harness plate 2 is disposed on the top outside of the top cover 11 . The circuit board 3 is arranged on a side of the wiring harness board 2 away from the battery 1 . The pressing part 4 is installed on the wiring harness plate 2 . The temperature collection component 5 includes a thermistor 51 , and the thermistor 51 is electrically connected with the circuit board 3 . The pressing part 4 presses the thermistor 51 of the temperature collection assembly 5 , so that the thermistor 51 is pressed against the top cover 11 .

[0052] The optional structure of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com