Battery module

A battery module and battery technology, applied in the direction of batteries, battery pack components, secondary batteries, etc., can solve the problem that the width and thickness of the connecting piece cannot be made large, the connecting piece exceeds the temperature inside the battery, and affects the discharge of the module. Power and other issues, to avoid early power limitation, optimize structure and performance, and shorten the temperature transfer path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

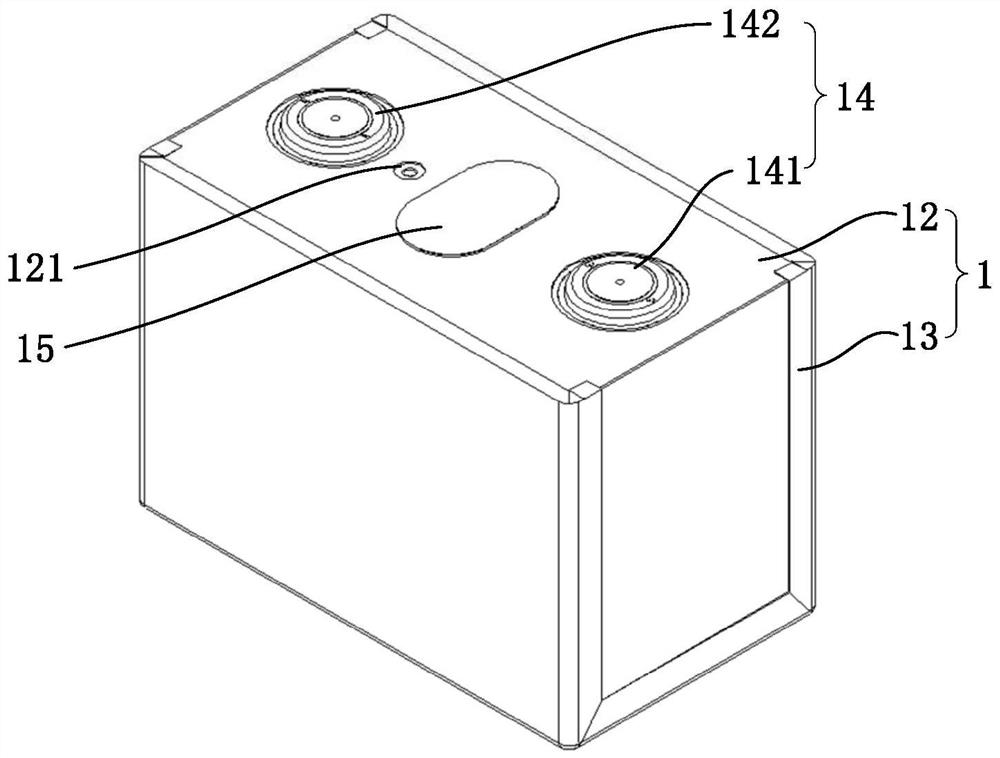

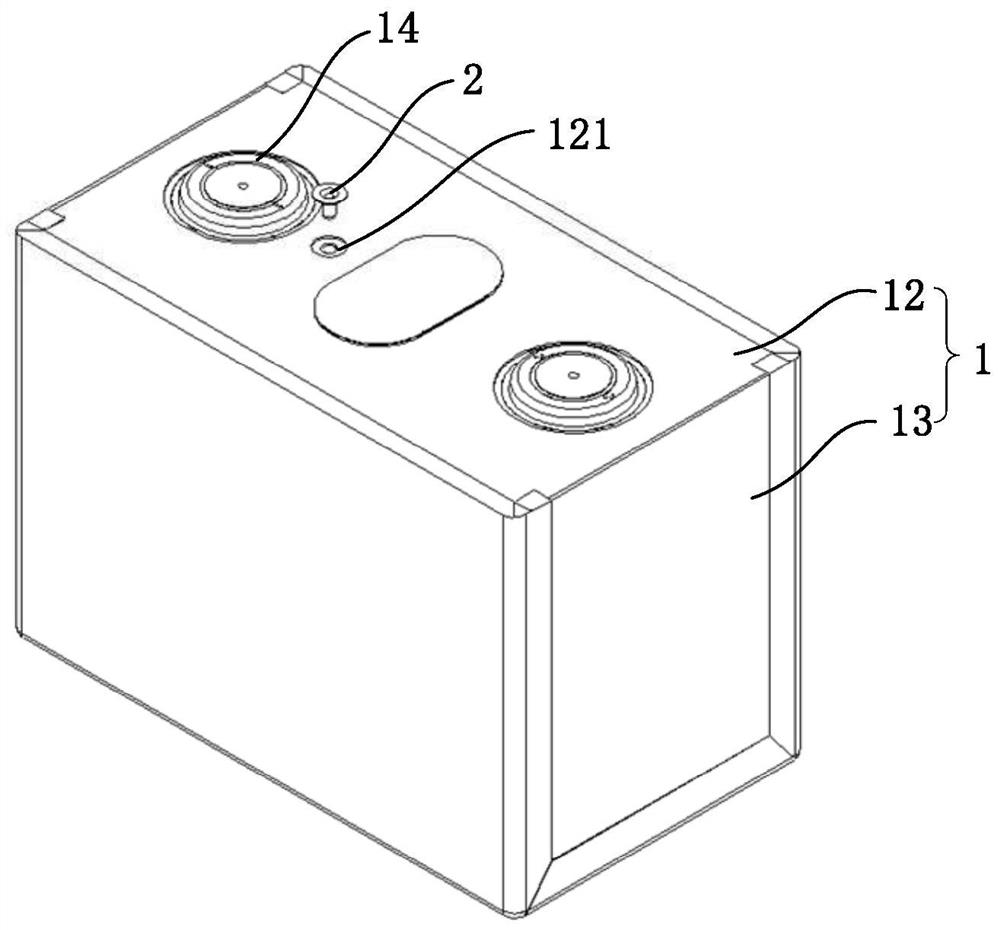

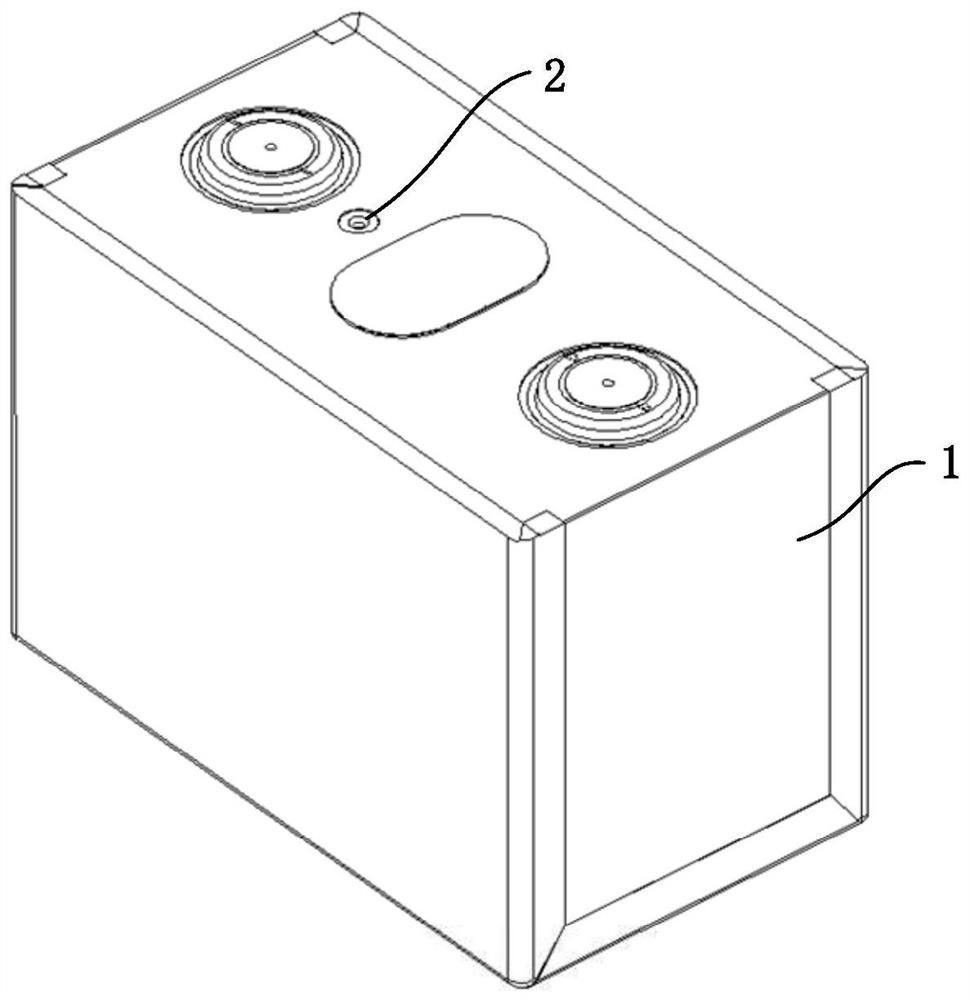

[0044] Combine below Figure 1 to Figure 17 The technical solution provided by the present invention is described in more detail.

[0045] see Figure 1 to Figure 5 , the embodiment of the present invention provides a battery module, including a battery 1 , a blocking member 2 and a heating component 3 . The battery 1 includes a casing 13 and a cover plate 12 connected to the casing 13 , and the cover plate 12 is provided with a temperature collecting hole 121 . The temperature collection hole 121 is, for example, a through hole, which can realize temperature collection on the one hand, and can also be used to inject electrolyte into the battery 1 . The blocking member 2 includes an insertion portion 21 which is installed in the temperature collection hole 121 and is used to block the temperature collection hole 121 ; The temperature collection component 3 includes a temperature collection part 31 installed inside the accommodating cavity 211 .

[0046] The optional struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com