A cleaning unit for a cleaning device for cleaning teatcups of a milking apparatus, and a cleaning device

A technology for cleaning units and cleaning devices, applied in milking devices, dairy products, applications, etc., can solve problems such as milking cup pollution, deterioration of cleaning device hygiene conditions, particle aggregation, etc., to achieve the effect of ensuring effective impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

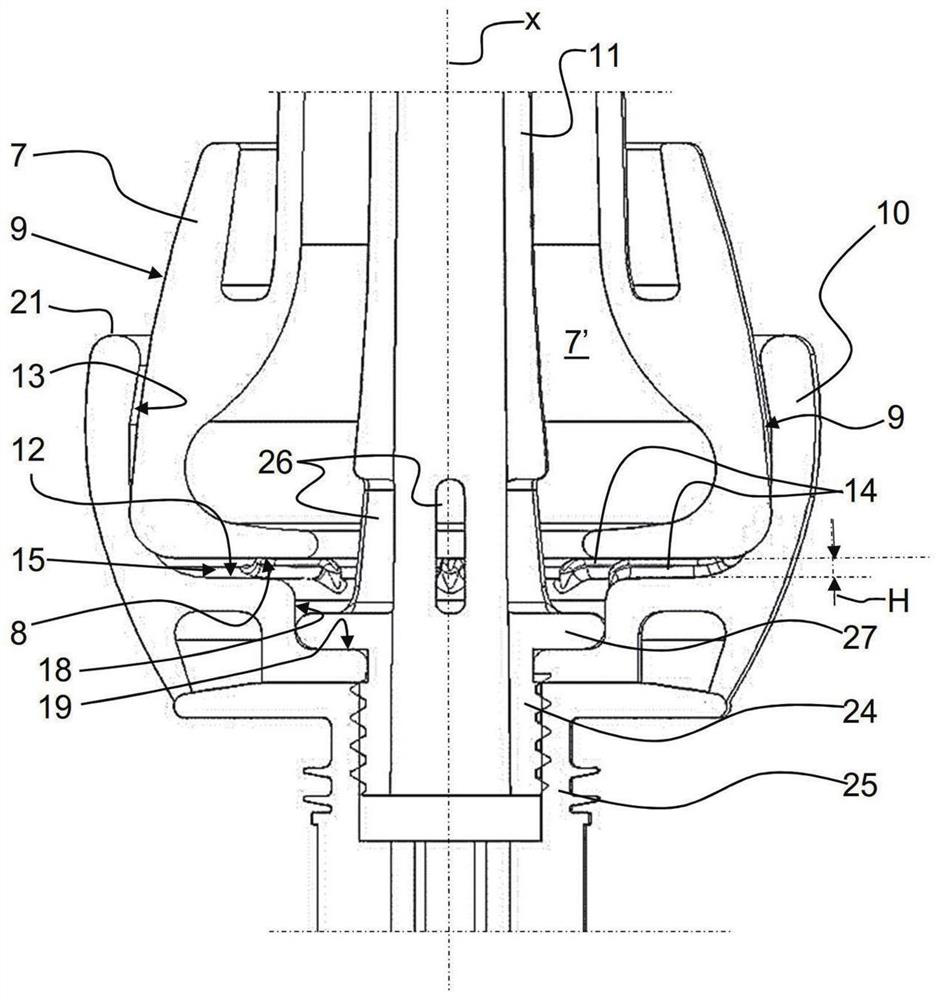

[0052] According to a first embodiment, the annular bottom surface 12 is perpendicular or substantially perpendicular to the longitudinal central axis x.

[0053] see image 3 and Figure 7 , each rib 14 may have a constant or substantially constant height H above the annular bottom surface 12 along its direction of extension. The height H may be of the order of 1-2 mm. The height H also forms the height of the gap 15 .

[0054] Each rib 14 may define an upper surface U. see Figure 7 , when viewed from a radial plane, the upper surface U may be straight or substantially straight to allow the upper surface U of the rib 14 to form a corresponding abutment with the upper end surface 8 of the teat cup 7 received by the cleaning unit 3, see image 3 . As mentioned above, each rib 14 and the extension of the upper surface U may be curved when viewed in the direction of the longitudinal central axis x, see Figure 6 .

[0055] As shown, especially in Figure 5-7 , each rib ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com