Vacuum sintering wax steam dewaxing device and dewaxing process

A technology of steam dewaxing and vacuum sintering, which is applied in the direction of using liquid separation agent, dispersed particle separation, chemical instruments and methods, etc. It can solve the problems of wax accumulation, leakage, and inconvenience of dewaxing in the inner cavity of the cooling tube, so as to reduce leakage risk, speed-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

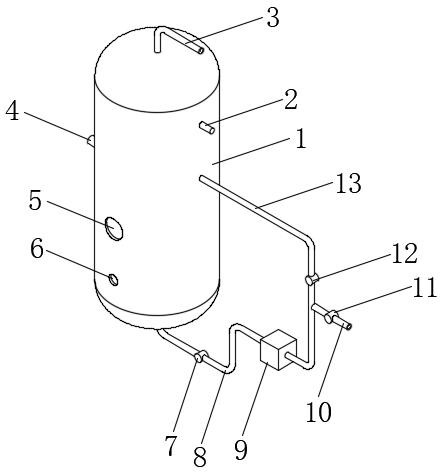

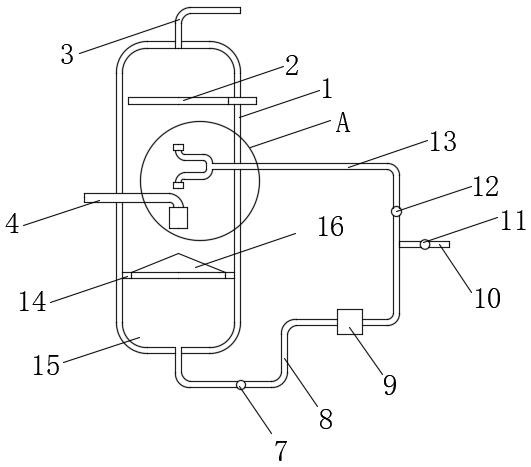

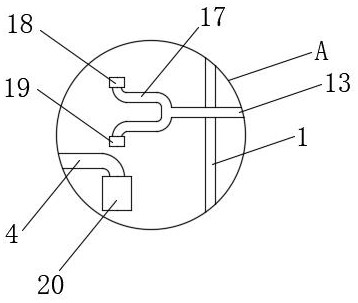

[0025] combined with Figure 1~3 The vacuum sintering wax steam dewaxing device includes a tank body 1, an air inlet pipe 4 is provided at the air inlet in the middle of the tank body 1, and an air outlet pipe 3 is provided at the air outlet at the top of the tank body 1, so that The inner end of the air intake pipe 4 extends to the inner cavity of the tank body 1, the inner end of the air intake pipe 4 is provided with a spray assembly 20, and the inner cavity of the tank body 1 is provided with a metal plate 16 at a position below the spray assembly 20 , the side of described metal plate 16 is provided with fixing column 14, and described metal plate 16 is fixed on the inner wall of tank body 1 by fixing column 14, and the top of described tank body 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com