Auxiliary device for aluminum profile pouring

An auxiliary device, a technology for aluminum profiles, which is applied to equipment for transporting molds, equipment for feeding molten metal into molds, and manufacturing tools, etc., can solve the problem of inconvenient assembly, inconvenient sand cleaning, unloading and size adjustment. and other problems, to achieve the effect of convenient unloading and size adjustment, convenient sand cleaning operation, and rapid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

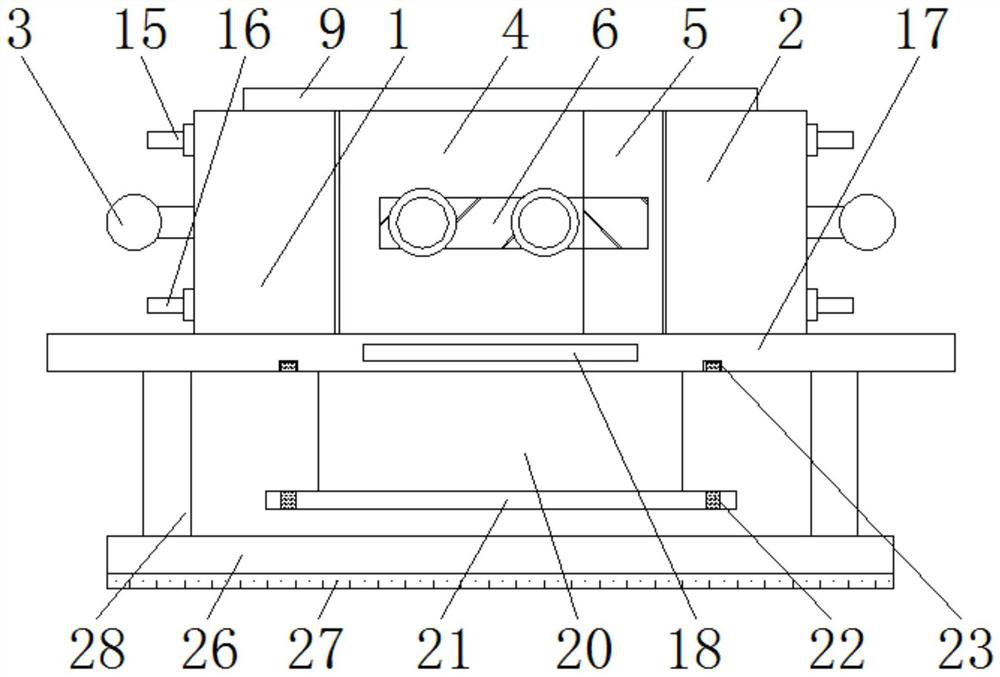

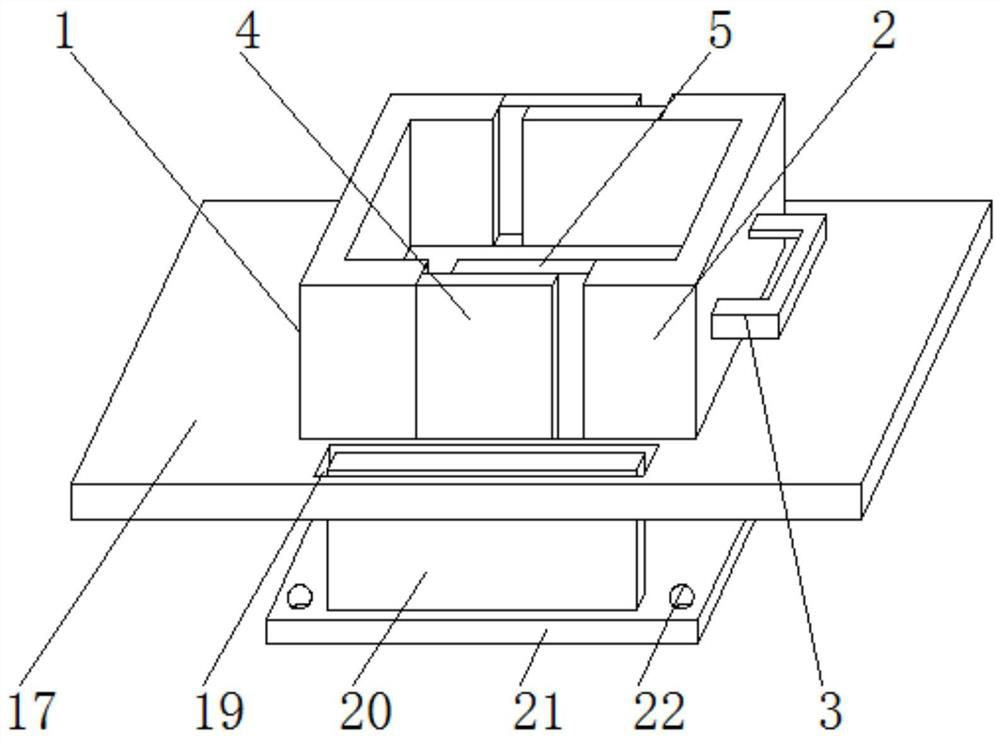

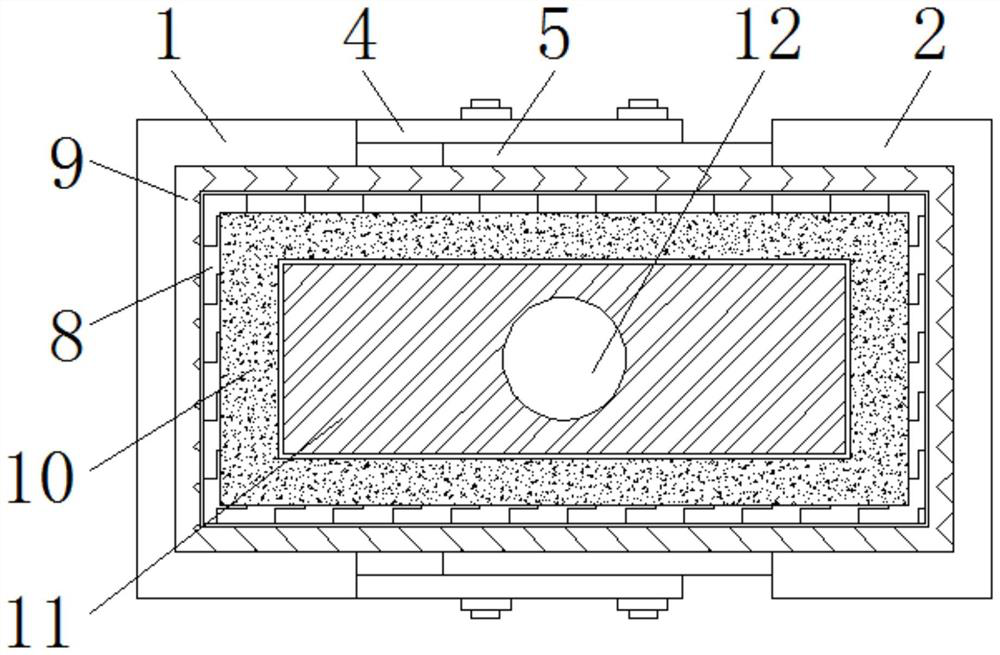

[0038] see Figure 1-6, the present invention provides an auxiliary device for pouring aluminum profiles, including a first clamping seat 1, a second clamping seat 2 and a base 26, the specifications of the first clamping seat 1 and the second clamping seat 2 are consistent, and the second clamping seat 1 A clip seat 1 and a second clip seat 2 are installed in reverse, the first clip seat 1 and the second clip seat 2 are combined into a frame structure, and the first clip seat 1 and the second clip seat 2 are away from one side of the outer wall The handles 3 are welded vertically in the middle position, and the outer wall positions on the side of the first clamping seat 1 and the second clamping seat 2 are respectively welded with a baffle plate 4 and a slide plate 5, and the number of the baffle plate 4 and the slide plate 5 is Both are two groups, the positions of the adjacent outer surfaces of the baffles 4 and the sliding plates 5 are in contact with each other, and the p...

Embodiment 2

[0040] see Figure 2-8 , the present invention provides an auxiliary device for pouring aluminum profiles, including a first clamping seat 1, a second clamping seat 2 and a base 26, the specifications of the first clamping seat 1 and the second clamping seat 2 are consistent, and the second clamping seat 1 A clip seat 1 and a second clip seat 2 are installed in reverse, the first clip seat 1 and the second clip seat 2 are combined into a frame structure, and the first clip seat 1 and the second clip seat 2 are away from one side of the outer wall The handles 3 are welded vertically in the middle position, and the outer wall positions on the side of the first clamping seat 1 and the second clamping seat 2 are respectively welded with a baffle plate 4 and a slide plate 5, and the number of the baffle plate 4 and the slide plate 5 is Both are two groups, the positions of the adjacent outer surfaces of the baffles 4 and the sliding plates 5 are in contact with each other, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com