Connecting rod length real-time active adjusting method and active anti-side-rolling torsion bar system

A technology of anti-rolling torsion bar and adjustment method, which is applied in the field of rail transit, can solve the problems of fixed and unadjustable connecting rod length, and achieve the effect of increasing operating speed, improving speed and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below by specific embodiment and in conjunction with accompanying drawing, the present invention will be further described:

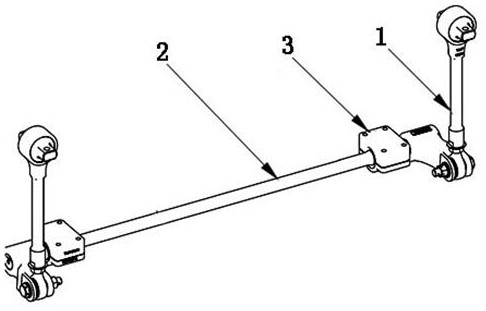

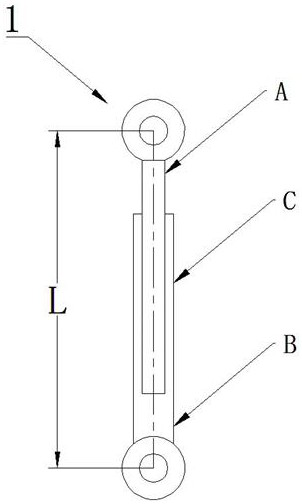

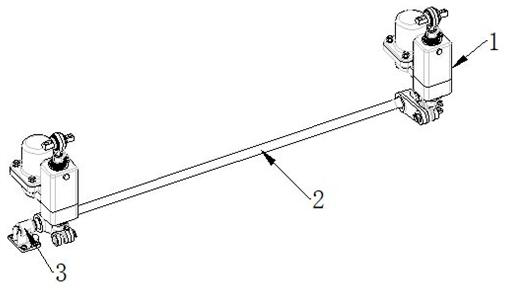

[0031] Existing torsion bars such as figure 1 As shown: including: connecting rod 1, torsion bar 2 and support seat 3, torsion bar 2 is fixed on the bogie through support seat 3, and the two rotating arms of torsion bar 2 are respectively connected to the two sides of the car body through two connecting rods 1 When the car body is tilted, the connecting rods 1 on both sides of the car body respectively drive the two pivoting arms of the torsion bar 2 to rotate in the opposite direction, so that the torsion bar 2 is torsionally deformed, thereby producing an anti-side movement in the opposite direction to the car body tilt. The rolling moment is used to balance the gravitational moment generated after the car body is tilted, so as to ensure driving safety.

[0032] Since the centrifugal force of the train turning has a tendency to cause the car b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com