A track maintenance vehicle with fire protection function

A maintenance vehicle and track technology, applied in track maintenance, track, track laying and other directions, can solve the problems of large manpower consumption and huge manual maintenance work of the track, and achieve the effect of reducing labor consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, goals and effects realized by the present invention easy to understand, the following embodiments describe the rail maintenance vehicle with fire protection function of the present invention in detail with reference to the accompanying drawings. The description is used to help the understanding of the present invention, but does not constitute a limitation of the present invention.

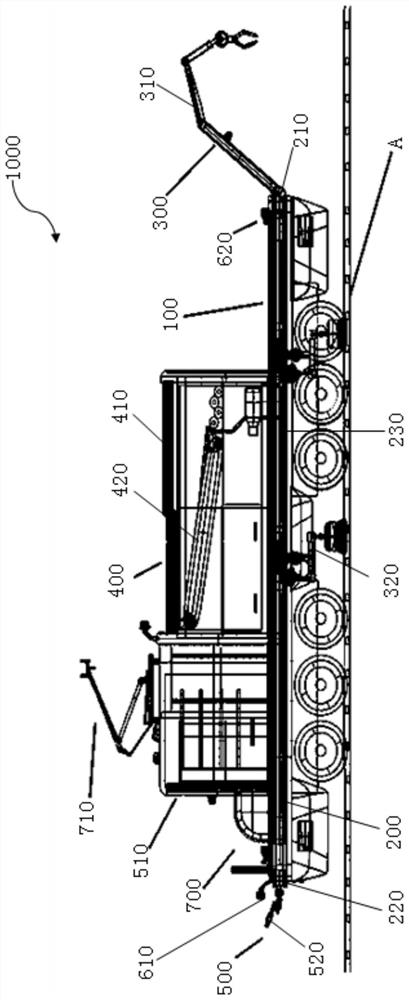

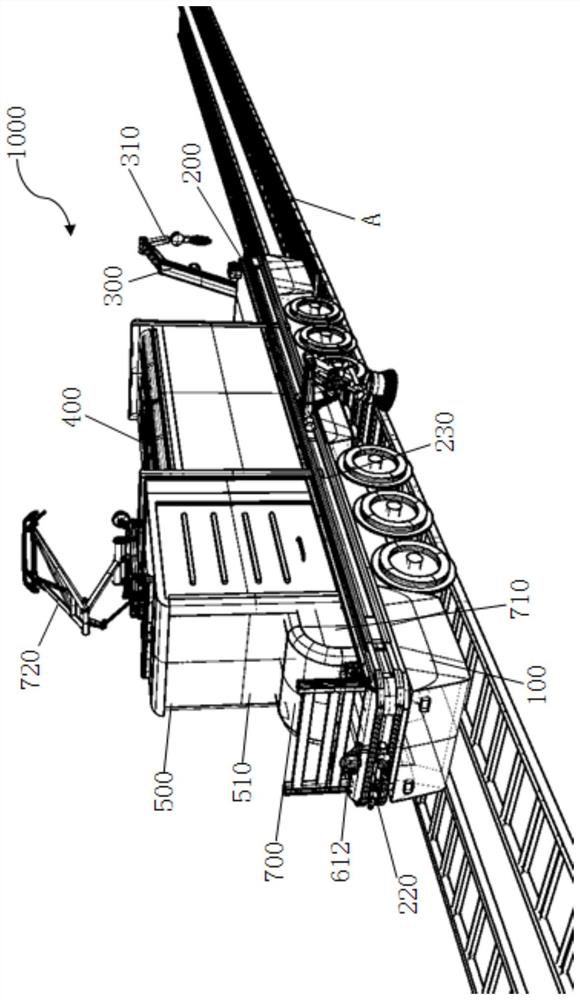

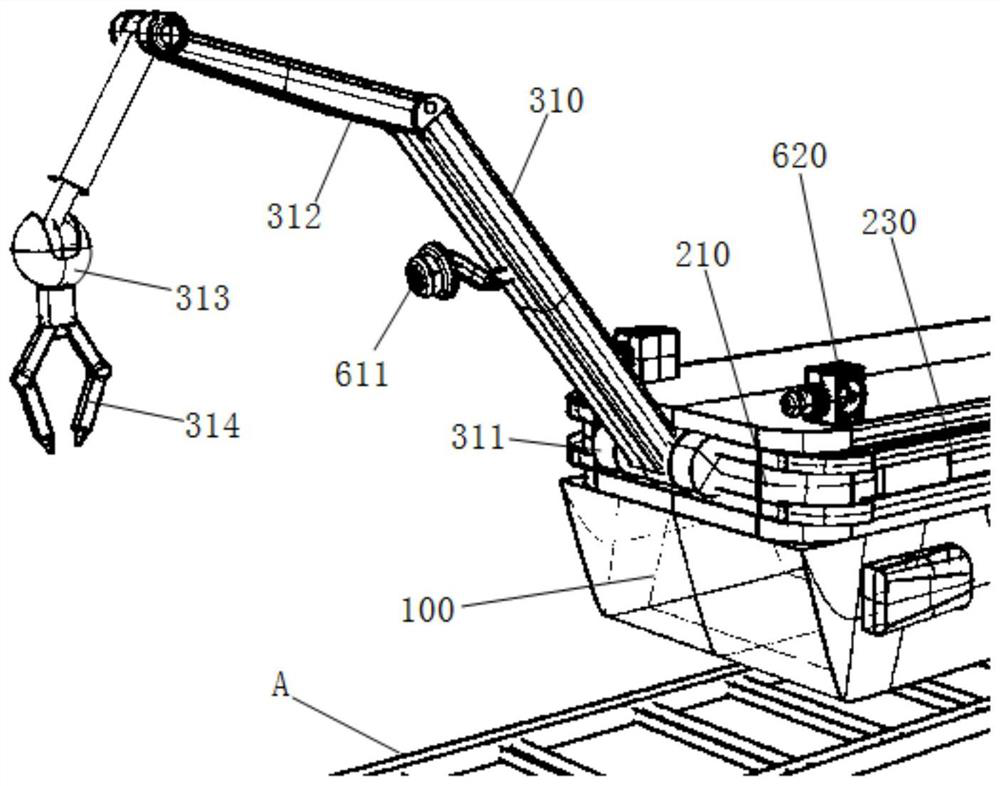

[0034] like Figure 1-2 As shown, the rail maintenance vehicle 1000 with fire fighting function in this embodiment includes a vehicle body 100, a lead screw assembly 200, a rail maintenance unit 300, a garbage disposal unit 400, a fire fighting unit 500, a control unit, and a power unit 700.

[0035] The vehicle body 100 has wheels for moving on the track A. In this embodiment, when the vehicle body 100 moves on the track A, its speed ranges from 14 km / h to 30 km / h.

[0036] The lead screw assembly 200 is arranged horizontally, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com