Intelligent production line cloud auxiliary self-organizing dynamic reconstruction method and application thereof

A dynamic reconstruction and production line technology, applied in data processing applications, instruments, manufacturing computing systems, etc., can solve problems such as poor flexibility, difficulty in achieving global performance optimization, and difficulty in adapting to a fast and dynamic manufacturing environment, so as to improve scheduling efficiency and effect, reduction of invalid competition, effect of efficient dynamic refactoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

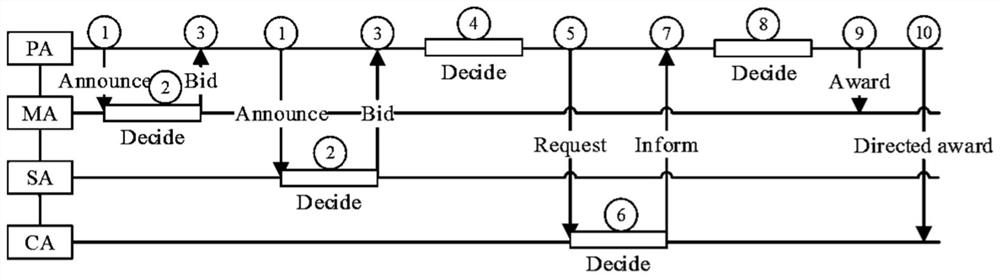

[0056] In this embodiment, a cloud-assisted self-organization dynamic reconfiguration method of an intelligent production line is provided. By building a dynamic reconfiguration mechanism of manufacturing resources in the flexible production process of an intelligent production line, the self-organization is mainly supplemented by cloud-level global feedback and Coordinated to obtain an organic combination of flexibility and high efficiency.

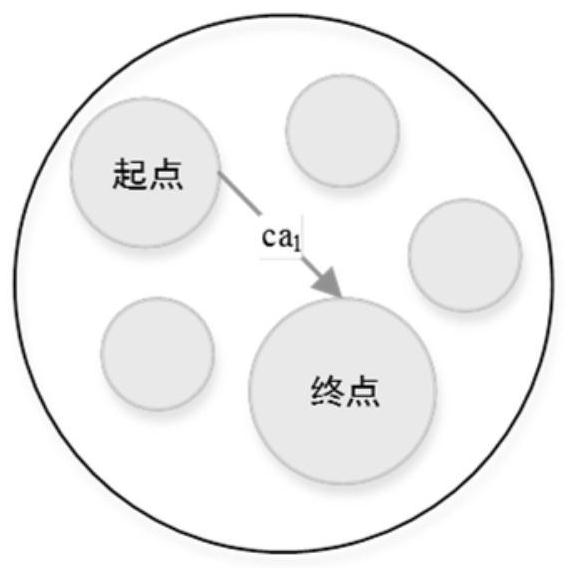

[0057]The intelligent production line cloud-assisted self-organization dynamic reconfiguration method in this embodiment divides physical manufacturing resources into four categories: 1) manufacturing agents (MA), representing equipment such as processing and testing; conveying agents (CA), such as conveyor belts and manipulators , AGV, etc., are used to move the workpiece; the workpiece agent (PA) represents the processed raw materials and parts; the cache agent (SA) represents the container for temporarily storing the work in progress. ...

Embodiment 2

[0086] This embodiment provides a cloud-assisted self-organizing dynamic reconfiguration system for an intelligent production line, including: a physical manufacturing resource division module, a manufacturing agent, a delivery agent, a workpiece agent, and a cache agent;

[0087] In this embodiment, the physical manufacturing resource division module is used to divide physical manufacturing resources to obtain manufacturing agents, transport agents, workpiece agents and buffer agents;

[0088] In this embodiment, the artifact agent is used to specify a specific operation sequence and initiate a task notification message;

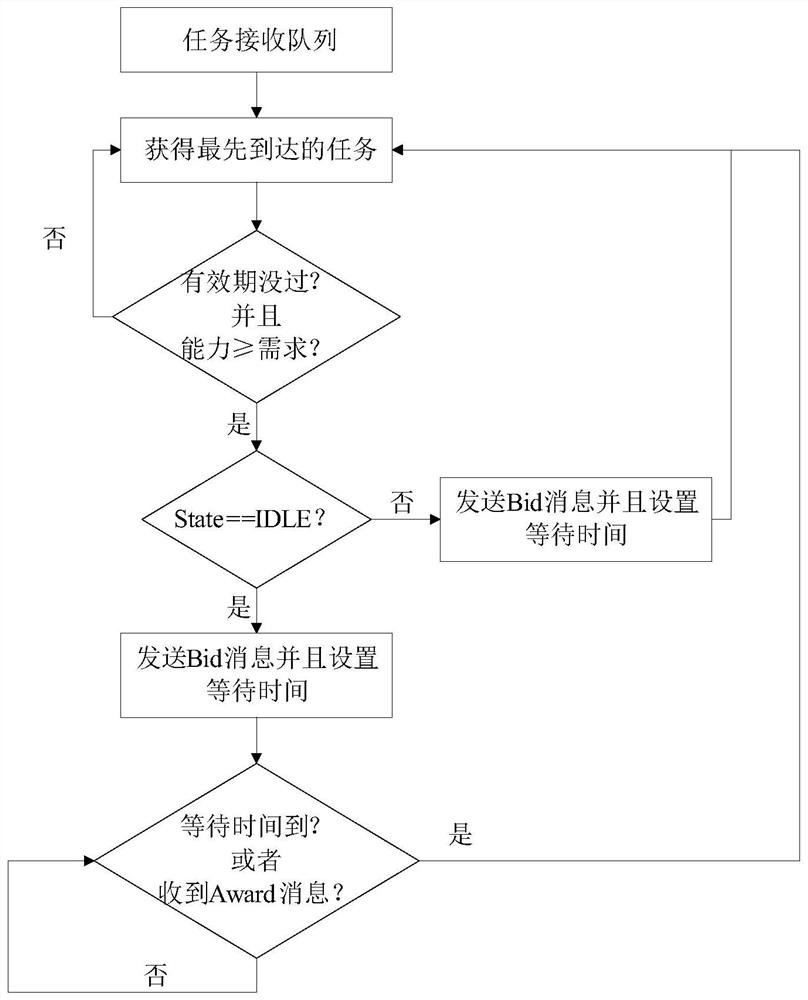

[0089] In this embodiment, the manufacturing agent and the cache agent are used to receive task notification messages and evaluate their own capabilities;

[0090] If the task can be performed and is currently idle, the manufacturing agent or cache agent sends a bid message to the workpiece agent; if the task can be performed and is currently busy, the manu...

Embodiment 3

[0096] This embodiment provides a storage medium, the storage medium may be a storage medium such as ROM, RAM, magnetic disk, optical disk, etc., and the storage medium stores one or more programs. When the programs are executed by the processor, the above-mentioned embodiment 1 is realized. Cloud-assisted self-organizing dynamic reconfiguration method for intelligent production line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com