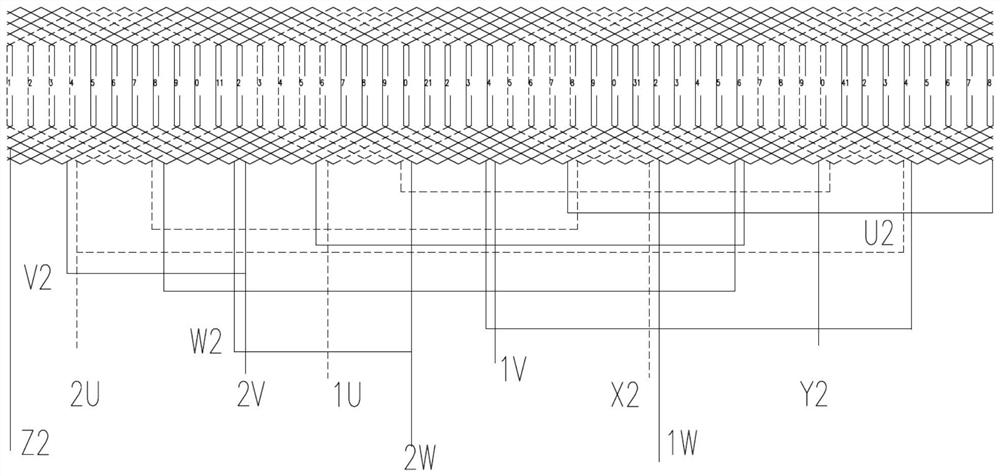

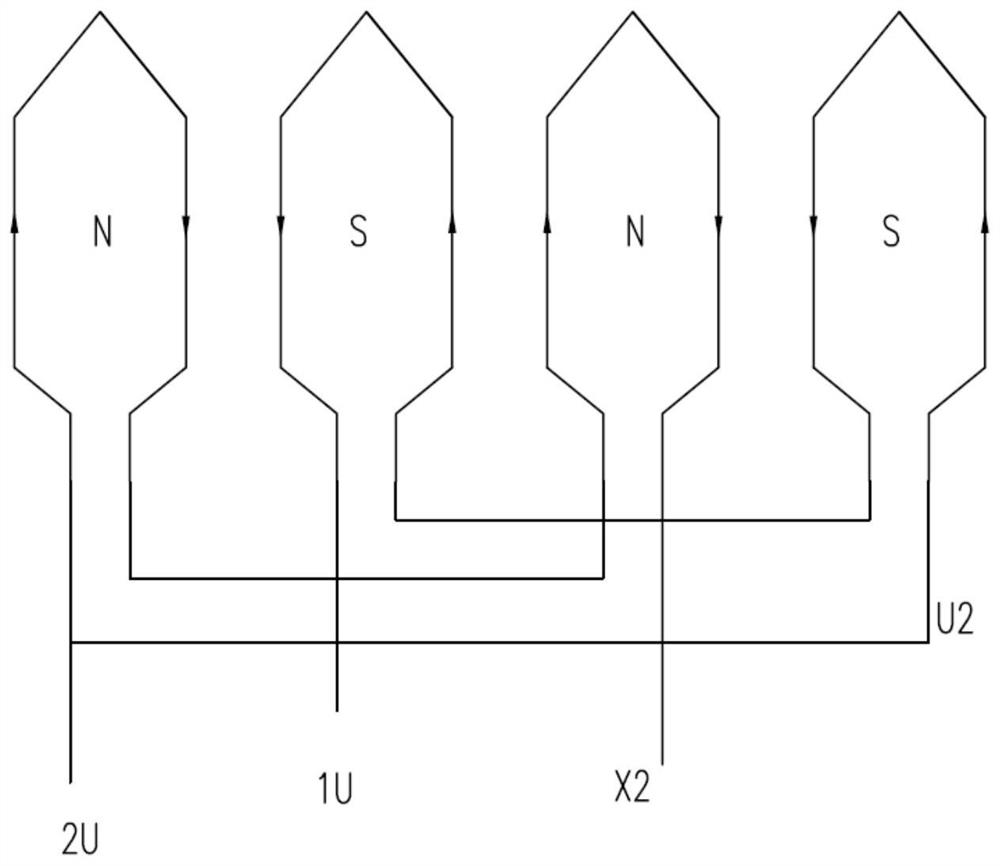

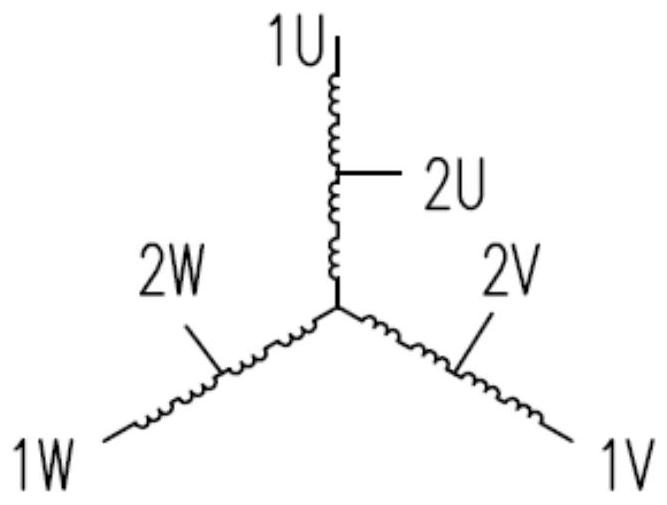

Double-layer lap winding winding structure for single-winding double-speed motor of nuclear power system

A technology of double-layer winding and winding structure, which is applied in the shape/style/structure of winding conductors, asynchronous induction motors, electrical components, etc., can solve the problems of poor material utilization, disadvantageous motor miniaturization, etc. , Conducive to long-term safe and stable operation, the effect of eliminating circulation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The number of stator slots is 48, the length of the stator core is 1060mm, the rotor adopts inclined slots, and when the motor adopts 4 and 8 poles, the corresponding synchronous speeds are 1500 rpm and 750 rpm respectively, and the corresponding rated power is 600kW and 95kW respectively The rated operating efficiencies at the two speeds are 80% and 68%, respectively. In the field application of a certain equipment, the steady-state current of the motor is 308A when the motor is running with 4 poles, and the steady-state current is 103A when the motor is running with 8 poles. The current amplitude is as follows: Figure 6 and Figure 7 Shown; when the motor is running with 4 poles, the speed is as follows Figure 8 As shown, when the motor is running with 8 poles, the speed is as follows: Figure 9 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com