Gemstone and manufacturing method thereof

A production method and technology of gemstones, applied in the field of diamonds or similar items, can solve the problems of insufficient anti-diamond fire and physical reflection effects, low directionality, close angles, etc., and achieve the effect of superior optical rotation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the purpose, technical solution and advantages of the present invention clearer, a solid stone and its manufacturing method of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

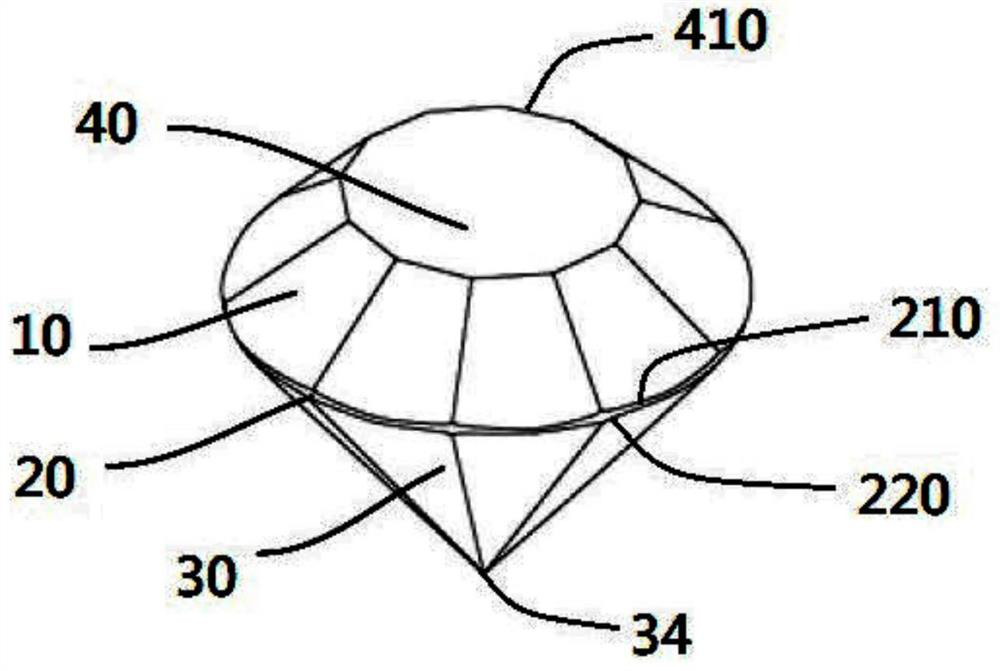

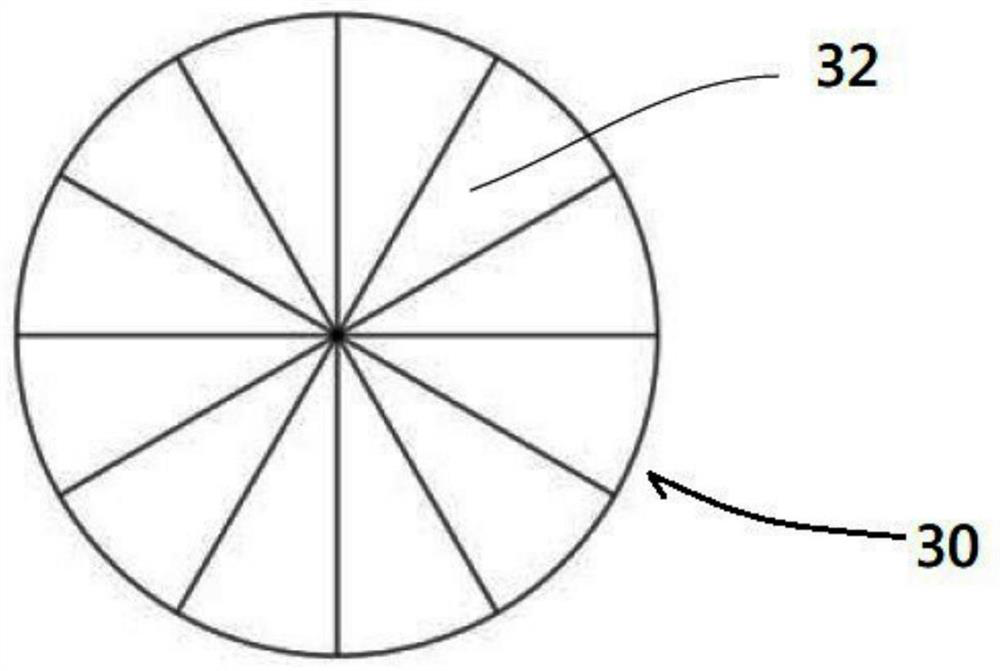

[0043] figure 1 A gemstone according to the invention is shown, consisting of a crown 10, a girdle 20 and a pavilion 30, wherein a table 40 is provided at the top of the crown.

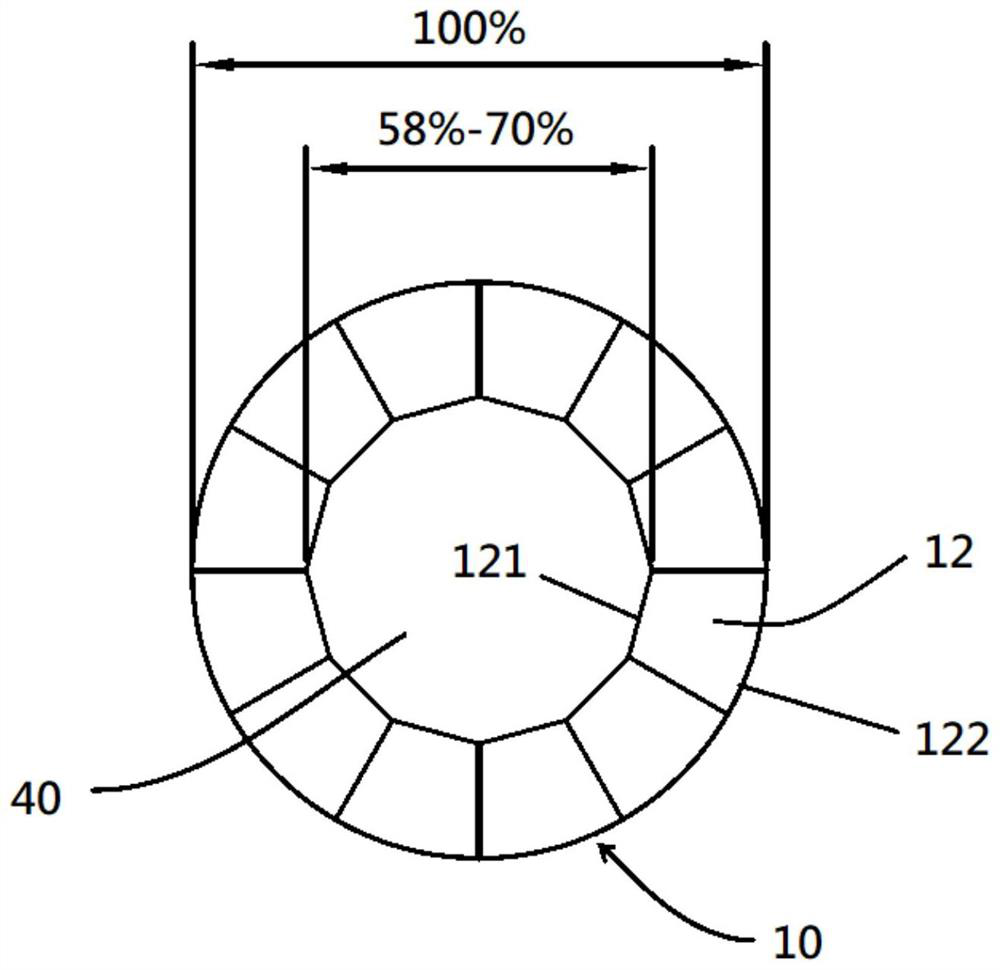

[0044] see Figure 1 to Figure 4 , the crown 10 has twelve equally divided beveled surfaces 12 , which are disposed between the table top 40 and the waist 20 , and are inclined from the table top 40 toward the waist 20 . The inclination angle of the beveled surface 12 relative to the horizontal plane, that is, the angle between the beveled surface 12 and the waist plane, is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com